Spiral mixer or wendel mixer? The decision as to which kneading system a company invests in is dependent on many influencing factors. The application engineers at Diosna allowed us to look over their shoulders during a series of tests and to document the results.

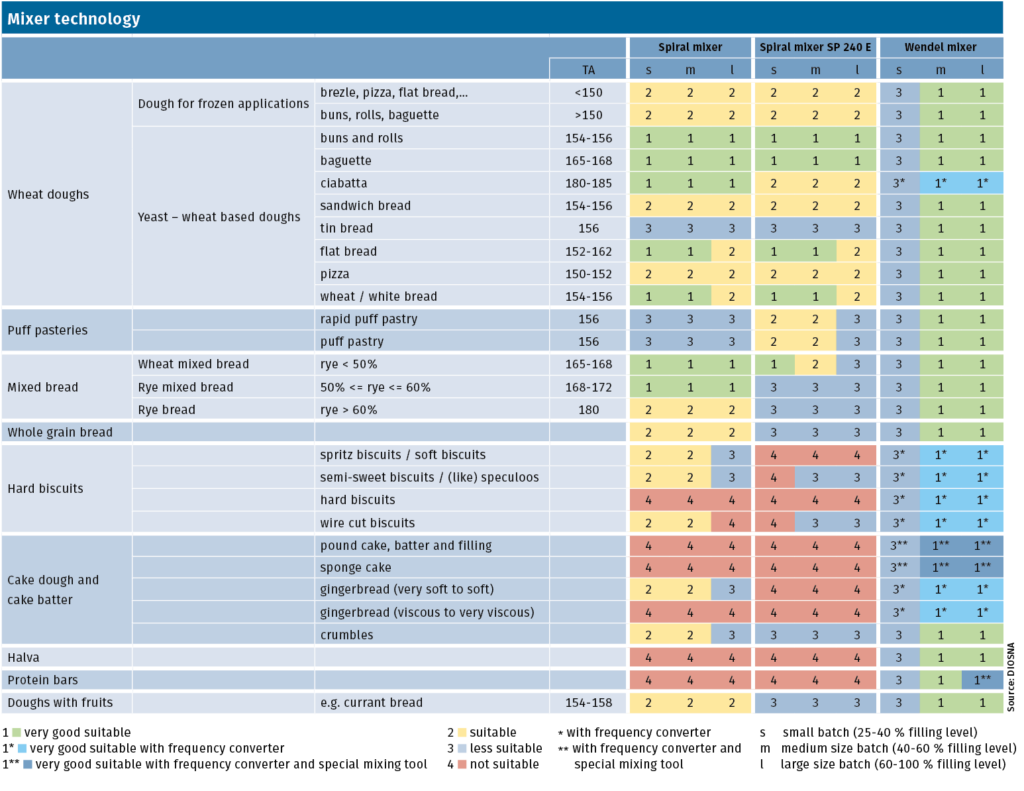

Spiral mixers are regarded as a universal solution for all yeast-raised doughs, while wendel mixers are more of a powerhouse, mixing and kneading large quantities in a short period of time. The wendel mixer also keeps the dough temperature within limits and often allows the dough to have a higher water content. Diosna’s application engineers have presented their assessments in a table generated by practical experience.

Diosna Spiral Mixer

Diosna Premium Wendel Mixer

This means that the choice between spiral and wendel mixer is highly dependent on product and batch size. Medium and large batches of bread roll dough with a TA between 154 and 156 are equally successful in both systems, as are baguette doughs with a water content of 65 to 68 % measured on the flour quantity. The wendel mixer requires a larger minimum filling quantity for kneading the doughs than the spiral mixer, and so application engineers advise against the wendel mixer for small quantities of dough. The rule of thumb for the wendel mixer applies: 30% minimum filling quantity should be reached.

In the case of Ciabatta pellets with a high-water content, the applicability of wendel mixers is improved by the use of frequency converters, which control the speed of the bowl and the tool differently and independently of each other. The targeted control enabled by the frequency converter improves water absorption and dough structure.

Spiral mixers are the second choice for most cookie and cake doughs and are also unsuitable for Halva or protein bars. Wendel mixers, however, are very suitable for these dough groups, especially if they are equipped with a frequency converter and, if necessary, special tools.

According to practitioners, the advantages of kneading systems also depend on the stickiness of the respective dough. This can be clearly seen in the category of mixed breads with a rye content of more than 60% and a TA of 180. For medium and large batches, experts recommend the wendel mixer, while for small doughs the spiral mixer is more suitable, namely specifically the one without center discharge. If the dough sticks, dough residues remain stuck during emptying and manual reworking is required.

Further factors for kneader selection

Filling quantity or batch size of the dough: Wendel mixers should have approx. 30-50 % of the maximum filling quantity per batch in order to achieve a good kneading result. Less than 10% of the filling quantity is sufficient to achieve a proper result in a spiral mixer.

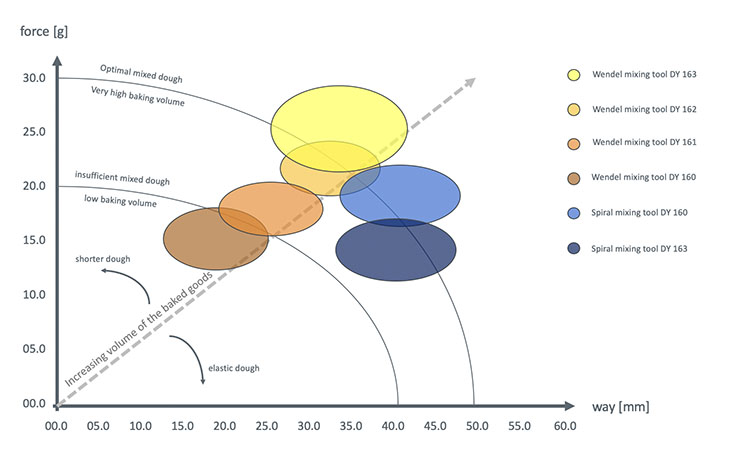

Kieffer Rig dough analysis for different mixing tools

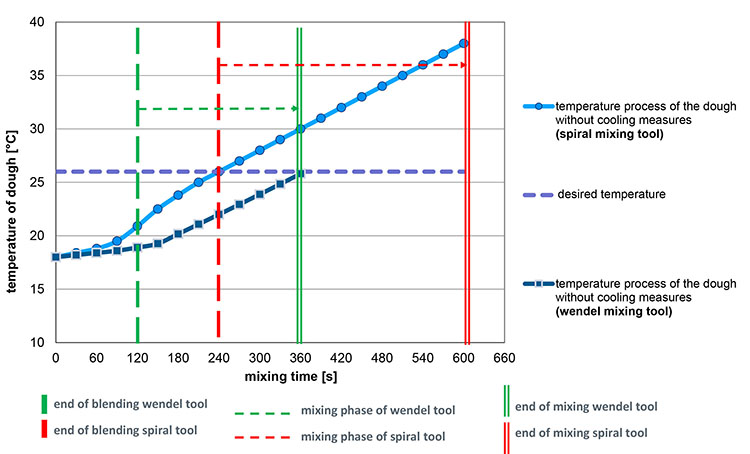

Pouring temperature of the water: It must be increased in the wendel mixer to reach the same dough temperature as in the spiral mixer. The efficiency of the two kneading systems in this respect is very different. While a Diosna spiral mixer without a center test bar adds approx. 1.5-2.5 °C/min to the dough heating during the high-speed kneading process, the special technical features of the wendel mixer allows only 0.5-1.5 °C/min to be achieved. In addition, it is advisable to knead the wheat doughs a little longer, since the gluten in the wendel mixer draws more strongly. For most doughs, a higher water absorption of 2-5% must be considered, at least when using European flours.

The viscoelastic properties of a dough are largely based on the hydration of the gluten. The protein fraction Gliadin contained in wheat ensures viscosity and flowability and the Glutenin provides elasticity. Their interplay or linkage during dough formation defines the elasticity and thus the gas retention capacity of the dough and is therefore decisive for the size and porosity of the pastry.

The Kieffer Rig test allows statements about the strength and elasticity of a dough. In trials, kneader manufacturer Disona has investigated the effects of spiral mixer and wendel mixer tools on different water/flour ratios under otherwise standardized conditions and uniform flour quality.

The graph shows that a dough in the wendel mixer with a TA of 163 has the same strength as a dough with a TA of 160 from the spiral mixer. The wendel mixer binds more water and thus has the capacity to produce a larger volume of dough. The same dough with TA 163 from a spiral mixer would tend to be too soft to retain structure.

Warming of the dough: spiral vs. wendel mixer tool

The wendel mixer offers better kneading, higher water absorption and less dough heating in a shorter time than a spiral mixer. Heat and energy input are higher with the spiral mixer than with the wendel mixer, not least because both the mixing phase and kneading phase of the spiral mixer takes up considerably more time.

Anyone believing they can make a qualified decision based on technical or technological differences alone could be mistaken, as it is not only the individual kneader type that counts, but the interaction with the entire process chain. Capacities of the individual process steps should be coordinated with each other as well as with the product range to be produced on this line.

Diosna Wendel Mixer

For example, does it make sense to produce large batches that may not be processed quickly enough, so that the dough quality changes during this process step? This requires either an ongoing adaptation of the control system of downstream equipment, which is hardly feasible, or the acceptance of fluctuating qualities of the end product. The problem can be limited with several, but smaller batches. However, if the same hourly output is to be ensured, more kneaders may be required. This is where the conflict between technology and economic efficiency may arise.

Dough resting times, proofing times, and interruptions in proofing, in turn, are reflected in the entire duration of the process and thus influence the batch size together with the selection of the subsequent process steps. The final temperature of the kneaded dough can also be of importance if the end product is not a ready-baked, but an unbaked frozen pastry. A low final temperature of the dough saves cooling energy.

Which kneading system is ultimately technologically and economically advantageous is not only dependent on selecting the right kneading tool, but needs to be assessed in conjunction with all the individual factors of the respective production system.

When selecting a kneader, the raw materials as well as the recipe, the end product including desired properties and the overall process must be considered.

B. Sc. Ing Florian Paschen,

Head of Technology Bakery at DIOSNA, Osnabrück/Germany.