Before the Dutch Kaak took over the Italian System and Oven manufacturer from Ala Italy in 2005, it was rarely a company contacted by pizza manufacturers. This takeover was the first step into a new market for Kaak. From this initial step, the company has grown to be a modern full-service provider for industry and semi-industry, and today builds systems for every form of pizza worldwide.

Kaak continues to supply swingtray proofers, pizza presses and tunnel ovens for industrial manufacturers as well as machines for the decoration of pizzas. The subsidiary in Nieuwkuijk, which has been part of Kaak for a long time and contributes alongside with the classical dough divider, rounder and pre-proofer, its wash-down capable two-shaft extruders and dough dividers that work without oil and control the size of the dough piece via the speed of the shafts.

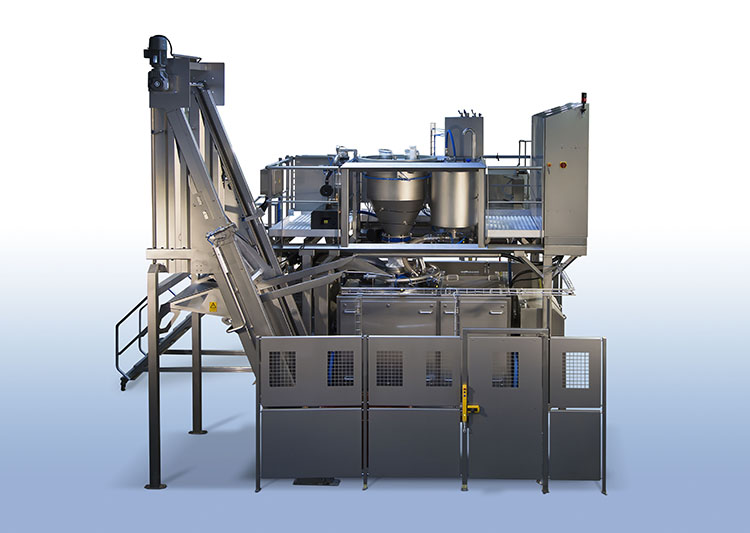

For large quantities of dough, however, Kaak also offers the “Mechanical Dough Developer”, a high-speed mixer that was developed as part of the so-called ‘Chorleywood Bread Process’. If necessary, the mixer can knead under vacuum or pressure and delivers up to 385 kg of dough within 4 to 5 minutes. The mixer, which is provided with a cooling jacket, can be combined with an automatic weighing and dosing system and offers a patented clean-in-place system.

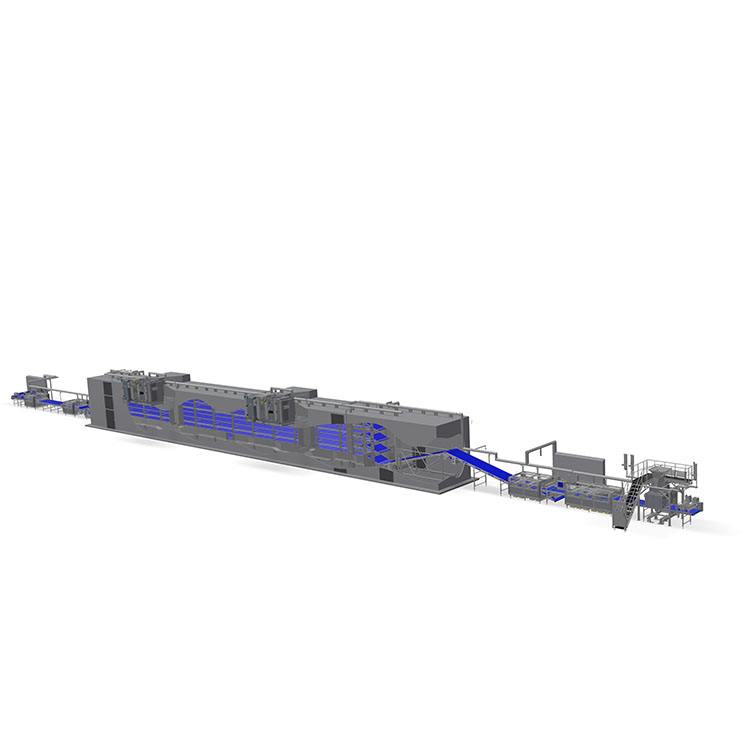

Pizza sheeting line with inline proofer

Kaak lines are used both for dough balls, which can be stored chilled until they are shaped in production or in the store for some days, as well as for complete lines that either press dough portions to the base using the hot or cold process or from the ‘cut out’ of a dough sheet. The technology of dough sheet production has been part of Kaak`s scope since 2009. New innovations include the combination of the dough sheet technology with the proofing system technology. The dough band of 50 to 60 m in length is sent through the proofer for 30 to 40 minutes and only then ‘cut out’ and baked on a belt. The rework dough goes straight back into the dough production. The process allows hourly outputs of up to 6,000 kg/h and enables a quick and easy product change.

MDD – the high-speed mixer that delivers up to 385 kg of dough per batch in 4 to 5 minutes

Up to 60 m long strips of dough are proofed on the belt, from which the pizza is then punched

According to Kaak, over the past few years, they have designed and built many lines for Italian-style pizzas (thin dough sheets). Dough balls are pressed with heated pressing heads directly onto the belt to the desired shape and baked on a stone belt after the tomato sauce has been applied, following which they are transferred to the oven.

In addition to the sauce nozzles and classic waterfall systems for sprinkling, Kaak has recently invented a special system that garnishes the edge of pizzas, so that it develops a

particularly strong aroma.

Kaak has also significantly expanded its range of spiral freezers for the pizza industry. They are designed with cleaning systems that fully automatically foam, wash and dry the entire freezer including the spiral – and, according to the company, in half the time that manual cleaning would require. All in all, the Kaak Group provides a full scope of bakery equipment for pizza manufacturing. From silo to truck, everything in one hand.

Pressing heads