As gluten-free bakery is decisively increasing its foothold into the mainstream market, growing by about 25% each year, research seeks to improve product taste, texture and nutritional profiles. In the absence of gluten, this has been a challenge. It takes exact science and technology to define and improve digestive wellness.

It all starts with the dough. Monitoring and thorough testing for ingredient variations will enable close control of the dough processing and, ultimately, the product’s quality; this is especially important when dealing with different types of gluten-free flour with varying characteristics. The goal is to reach the ideal dough viscosity, which is unique to each, from corn-based dough to chickpea-based dough, for instance. Baking trials will help determine optimum values in each case. Also, a fundamental understanding of the ingredients and their individual physicochemical characteristics, such as solubility, gelling and emulsification properties, can help to predict their impact on viscosity – a key indicator of the dough and the quality of the final baked good.

From the start of the process, the dough’s kneading properties offer useful information that can support formulation development. As single ingredients are added or changed, their effect on the whole dough system can be measured, necessary steps when developing products made by gluten-free flour. The International Association for Cereal Science and Technology (ICC) recently held a joint webinar with guest experts Aylin Sahin, a postdoctoral researcher at University College Cork (Cereal and Beverage Science Research Group), and specialists from Brabender – Stefan Jansen (application engineer) and Jessica Wiertz (manager Applications). We spoke with the specialists to further delve into the science explaining and supporting high-quality gluten-free bakery. “The right water absorption is one of the main important criteria for a proper crumb and a good product. Measuring the flour or the whole gluten-free formulation during kneading provides a helpful indication of how a gluten-free raw material acts during production. Moreover, different types of mixers cause different energy input during kneading which has a great impact on the development of any network,” they elaborate.

Viscosity control ensures quality

Consistent, quality gluten-free products begin with the incoming raw materials. Water absorption is an indicator that should be monitored from the start, as specialists recommend, to ensure the quality of incoming flour is as expected. In the R&D stage, when dough formulations are developed, the ideal viscosity is trialed or a certain viscosity can be targeted. For example, the target consistency for a chickpea flour will be 44 BU (Brabender Units), while corn flour will have 150 BU – vvalues based on dough systems including 2% hydroxypropyl methyl cellulose (HPMC, gluten replacer). Not only do the different types of gluten-free flours differ quite a lot, but there is also notable variation between different types of corn flours, the experts say. They illustrate that the particle size distribution is one of the factors responsible for this, e.g., if finely ground corn flour or corn grits are used; the target application for the flour analyzed also gives an indication for the right level of water absorption.

The International Association for Cereal Science and Technology

Today ICC is one of the foremost international organizations in the field dedicated to international cooperation, the dissemination of knowledge, and the improvement in safety and quality of cereal-based foods. The Association has its headquarters in Vienna, Austria with members from all five continents represented.

While raw materials may have varying characteristics, they should be within acceptable ranges to obtain constant quality gluten-free products, as each set of qualities may be suitable for certain applications. There are weak glutens and strong glutens, and several qualities in between; weak gluten flour is good for wafer production, for example, while wheat bread loaves are a better match for strong gluten flour. The specialists underline that protein content should be paid attention to, as it is a rough indicator for the flour’s performance, but protein quality is getting more and more into the focus: “Nowadays, it’s getting more common to describe the flour quality by protein quality instead of protein content.”

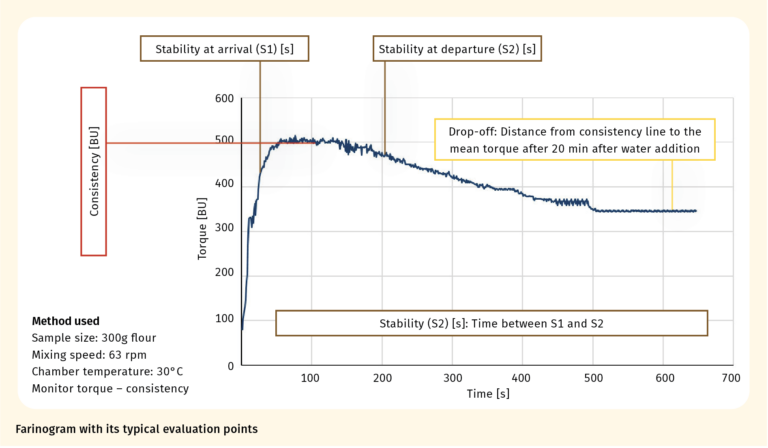

To differentiate among gluten qualities, the Brabender GlutoPeak offers methods for pure gluten analysis and for gluten-containing flour analysis. Within minutes, a characteristic gluten aggregation curve is recorded, and the quality and end use of the gluten or flour can be assessed. To optimize the water addition level, Brabender’s Farinograph, a rheometer with a sigma-blade-mixer, is well-established within the milling and baking industry. For the gluten-free flours, a modification of the existing mixer is necessary, the specialists note: “A tool called FarinoAdd-S300 is attached to the mixer and keeps the gluten-free dough in the mixing area.” This tool can be used to develop products with lesser-known raw materials, including hemp flour, buckwheat and quinoa.

Ingredients and recipes

The most important functional ingredients of a gluten-free dough and bread are the hydrocolloids and proteins. Both play an important role in terms of water binding, and also improve the visco-elastic properties of the system. Furthermore, sourdough can be added to the formulation to improve the baked good’s quality, the specialists highlight. Lowering of the pH value this way has several benefits, from increasing shelf life to reducing staling and lowering the pH of the system.

When formulating gluten-free products with additional ingredient claims, dietary fibers are a popular choice. They mainly influence the water absorption; however, they also physically affect the dough network. It might be therefore necessary to take countermeasures, e.g. by a pre-treatment of the fiber, which can be done by milling, hydration or functionalization, Brabender’s experts recommend.

To further enhance the nutritional profiles of gluten-free goods, plant proteins are a good place to start. In this scenario, the maximum level of protein content in the range of an acceptable sensory profile has to be determined, first of all. To further improve sensory characteristics, the combination of different protein types as well as the addition of enzymes can help. The specialists also recommended assessing the maximum level that can be added as they can affect the product’s mouthfeel. To optimize sensory characteristics, pre-milling, pre-hydration or heat treatment can be used. The addition of hydrocolloids together with the fiber as a premix can be suitable; alternatively, enzymes can be used.

In conclusion, accurately monitoring the process and the ingredients supports the further developments for all characteristics of gluten-free products, from working with functional

replacers to improving the product’s taste and shelf life.