By means of invasive mechanical and electrical impulses, the dough resting time of wheat doughs after mechanical energy input can be drastically shortened and dough properties equivalent to those of rested doughs can be achieved quickly in seconds.

The mechanical/electrical stimulation for the optimization of the dough resting time for wheat pastries is an AiF/FEI funded research project, which was carried out at the TU Munich, Chair of Brewing and Beverage Technology in the working group Grain Technology and Process Engineering. The project aims to reduce the time-consuming and process interrupting rest periods in bakery production to a minimum, so that the process steps of dough relaxation can be integrated in-line into existing processes and process interruptions due to rest periods, can be eliminated. Although some engineering-based solutions are already available for continuous dough processing without relaxation phases (e.g. extrusion processes), these are often unsuitable due to the size of the plant. Alternatively, they often represent special solutions for specific applications [1] and, in some cases, result in products with modified textural properties [2]. Consequently, the solutions currently available on the market are unsuitable for most products and companies. As a result, more complex processes with the intermediate step of dough resting have to be observed for most baked goods.

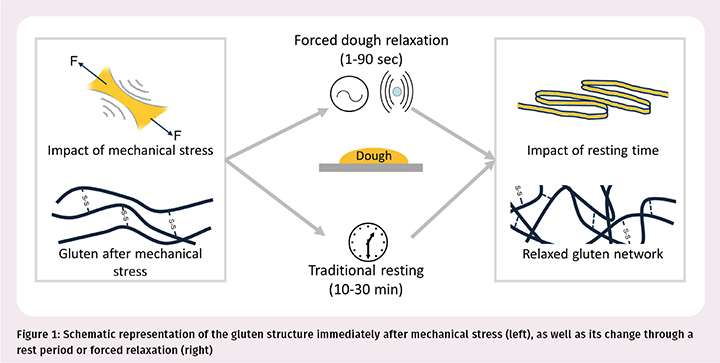

This is due to the structural properties of wheat dough. After a mechanical energy input, such as kneading, the gluten network is very elastic. This limits the dough’s ability to be processed by machine. In the subsequent resting phase, the gluten network is restructured, which changes the mechanical properties of the dough. Relaxed doughs are more plastic and have a higher extensibility and yielding. This change in the dough properties is an absolute prerequisite for successful further processing. Without them, perfect dough division or shaping by machine would be drastically impeded [3]. Depending on the kneading technique and gluten quality, these resting times range from 10 to 30 minutes [4]. Depending on the product, many companies also use rest periods between the rounding and long molding, as otherwise the surface could burst open due to the excessive stress during baking. The sequence of mechanical loads with subsequent relaxation phases is therefore essential in order to develop the desired structural properties in the end product. A method that enables dough properties corresponding to those of rested doughs to be achieved in just a few seconds therefore represents a significant potential for process optimization and shortening for all doughs containing gluten. Particularly in view of the fact that every German household on average consumes just under 58.9 kg of bread and baked goods per year and 67% of these baked goods come from bakeries of an industrial character [5], the integration of dough resting in the ongoing process (in-line solution) would be associated with a high potential for increasing efficiency. However, regardless of the size of the company and the degree of automation, shortening the dough resting time basically allows for a simplification and shortening of the process sequences.

Invasive impulses, mainly electrical, but also partly mechanical, have proven to be suitable to accelerate the restructuring processes of the gluten network during the resting period. The electrical pulses are applied in the form of alternating voltage in a voltage range between 110 and 260 V for application times of 1-5 seconds. For the application of mechanical pulses, high-energy sound (20 KHz) with amplitudes of 5 to 30 µm and application times of 30 to 120 seconds are used. The experimental setups are shown in figure 2 a) for alternating voltage and 2 d) for ultrasound. Immediately after kneading, the doughs are subjected to forced relaxation and compared with the properties of unrested and rested wheat doughs via various laboratory analyses and baking tests. Forced relaxed (voltage treatment) doughs in particular show the same behavior as rested doughs in all measured properties (extensibility, yielding, relaxation behavior). Figure 2 b) shows that the elongation of a forced relaxed dough (200 V, 2 sec) corresponds approximately to that of dough that has been rested for 25 minutes. Looking at the softness, the potential of forced relaxation becomes even clearer: here, the softness of the forced relaxed dough corresponds to that of dough rested for 50 minutes. For the ultrasonically treated doughs, the effect on the extensibility is similar to the effect of a voltage treatment (Fig. 2 e)). Here, too, elongation is achieved that corresponds to dough that has been rested for 15 to 20 minutes. However, ultrasound shows no effect on the extensibility. In this case, the ultrasonically treated dough corresponds to the dough that has not been rested (Fig. 2 f)). These corresponding viscoelastic dough properties between forced relaxed dough, especially voltage treated dough, and conventionally rested dough show that the restructuring processes of the gluten network can be forced and controlled by electrical or mechanical impulses.

Since the impulses used for forced dough relaxation are invasive applications that actively modify biological structures, it is essential to assess the vitality of the yeast and the baking capability of the dough. Standard baking trials with tin loaves of white bread serve this purpose. Doughs that rest for 0, 10 or 20 minutes between kneading and processing are used as a reference. The forced relaxation is also carried out between kneading and processing by means of alternating voltage (260 V 1 sec) or ultrasound (amplitude 18.9 µm 60 seconds). The remaining process steps (kneading, proofing and baking) are kept identical in order to allow a comparison of the two processes. After baking, the breads are analyzed by measuring the volume, crumb hardness and pore pattern. As already indicated in the results of the dough analysis, the identical properties of the forced relaxed and conventional rested breads can be confirmed with regard to their volume and crumb hardness, especially for voltage treated doughs (results not shown). Likewise, after baking, there are also effects equivalent to resting time for ultrasonically treated doughs with regard to volume and crumb hardness. However, the effect of ultrasonic treatment is significantly lower compared to stress treatment. This also becomes apparent when the pore pattern of the reference breads with 0 and 10 minute rest time between kneading and processing is compared with the pore pattern of the forced relaxed breads (Fig. 3 a)). The 10 to 20-minute rest period between kneading and processing gives the breads a coarser-pore structure. This can also be seen from the decrease in the number of pores with a simultaneous increase in the proportion of pores in the total area of the bread slice (Fig. 3 b)). The pores are thus reduced in total by the resting period, but become larger. A nearly identical effect as a 20-minute resting period becomes apparent for the voltage treatment. This can be seen visually as well as via the non-significantly different number and area of pores. The ultrasound treatment also shows a resting time equivalent effect on the pore pattern, but this corresponds to a resting time of about 10 minutes. With the results of the baking tests, the effects of forced relaxation on structure and/or yeast damage can be excluded and bread properties (volume, crumb hardness, pore structure) can be demonstrated to be equivalent to those of dough that has been left to rest.

The easy applicability and short application time (1-60 sec) of the electrical/mechanical impulses allows the integration of the dough resting step into the running process. This leads to a simplified and more effective process in terms of plant effort and time. The detailed micro- and macrostructural analyses, some of which are presented here, consisting of rheological analyses, strain measurement, microscopic methods and baking tests, have clarified the underlying functional mechanisms of forced dough relaxation for different flour qualities. Based on the presented shortening potential, existing process sequences in bakeries were evaluated with respect to their suitability (dwell time for application of the impulses) for the integration of the relaxation methods: Conveyor and transport belts in particular proved to be suitable application points. In summary, the forced dough relaxation is a method that allows for the elasticity, softness and resilience of wheat doughs in a few seconds without significantly changing the gas release and holding capacity of the products.