This year, KAAK celebrates its 175th anniversary. Lodewijk van der Borg (CEO) and Theo Lammers (COO) granted us an interview with this occasion at the forefront and shared how the Group was shaped around the silo to truck’ concept, the defining moments in its impressive timeline, changes old and new, and how its member companies build on each other’s expertise to advance in their field and provide comprehensive solutions.

Picture above: From left to right: Lodewijk van der Borg, CEO, Koos Frowein, CFO, Aart-Jan Hartman, CCO, and Theo Lammers, COO.

Mihu: The year marking the Group’s 175th anniversary is also when Silowacht further enhances KAAK’s ‘from silo to truck’ know-how. What does this motto represent for the company?

Lodewijk van der Borg: Over the past 50 years, if there was an opportunity to add a company that filled a gap within our portfolio, we took it. With Silowacht we now provide a complete project, starting from the silo up to the crate, and fully commit to our ‘silo to truck’ slogan that has represented us for the past 20 years. We have been building on this concept by acquisitions and incorporating areas of specialization into our offers so that we could be a one-stop-shop for our customers.

As supermarkets started baking their own bread, especially in the West European markets, they welcomed our approach; they were not originally bakers and were very receptive to finding solutions to all burdens of such projects with the KAAK Group and automating their processes.

Mihu: Going back to KAAK’s beginnings, how has it developed from a single company to the comprehensive Group with all the related services it is now?

Lodewijk van der Borg: The company started in 1846 as a roofing business. Jan Hendrik Weenink then passed it on to his son Jan, who changed its focus to metalwork. Bernard Kaak took over the company next (1881) when he married Weenink’s widow, Bernadina, and the business went on to produce sheet metal bakeware. He was the great-grandfather of today’s owner, Mr. Jan Kaak. Sometime around WW2, KAAK started building the first straps for local bakeries. At the time it was one of the few who was able to produce them, so more bakers became customers. In the 1960s, the company started to automate its equipment and became a supplier for a large company called Benier.

At the beginning of the 1990s, Benier found itself in rough waters and went bankrupt and consequently became the first addition to the company turned Group. In 1997, Daub (part of Krupp) was acquired into the Group. Dough preparation was covered by Benier, the proofers and handling systems were provided by KAAK, and the ovens by Daub. This is how the motto ‘from silo to crate’ began. MCS joined next, in 2005, specializing in ovens, proofers, and pizza lines. In 2007, we bought Lhotellier – which meant adding coating expertise to our bakeware. In 2009, we launched DrieM, a start-up for sheeted production lines, and in 2016 JAWS (the English word for ‘KAAK’) followed, our recruitment firm to help us find the right employees in the Netherlands and abroad. In 2019, we started K3D and went into 3D printing. This brings us to this year when Silowacht was added to the Group.

Theo Lammers: Going forward, we have ambition for growth and the possibiltites are also there, we believe. When the right train comes along, we get on board.

Mihu: The company has grown a good deal recently despite the challenges. How did KAAK overcome such hardships?

Lodewijk van der Borg: The company was relatively small until the 1960s; and up until that time, there were at most 25 people working at KAAK. During WW2, the company was closed. The financial crisis in 2008 was a more difficult period than the current COVID situation, because we were already very well prepared to work remotely before the travel bans. All our lines and equipment were able to cope with people not working on-site so we could very easily shift to everyone working from home. We started making working cells (‘bubbles’) as soon as March 2020. The bread market was not affected by COVID-19 dramatically; there was a shift in convenience food, but production for supermarkets and packaged bread is performing well. This helped to balance our turnover a bit; it was slightly less in 2020, but profitability was good and we were mostly unaffected by COVID.

On the other hand, production was never halted over the past year and a half for projects in Netherlands, Germany, France, Belgium as we were able to arrange complete, isolated working bubbles together with the customers. We proved that this works, as we have had almost no cases of COVID within these groups.

Theo Lammers: When COVID started, we reacted quite fast. Our engineering department started working from home, with only about 20% of our engineers left on-site. We invested in home workplaces and we still have about 75% of our staff working from home at present. Within our production, we instated distinct cells of team members with largely isolated facilities, which were not allowed to overlap. This workflow helped us adjust to working with customers without visiting them, to sell and support lines from a distance.

Mihu: After the steep learning curve brought on by COVID-19, how is 2021 shaping up to be?

Theo Lammers: This year, government measures will still be in effect in several countries. We are expanding our workforce with local specialists to perform installations at the customer’s sites.

Lodewijk van der Borg: Five years ago, when we were anticipating what the future would be like for the next 10-15 years, we agreed that environmental issues will drive business. We then took some steps in this direction – the first one was commissioning at a distance. We were already on this path when COVID hit, which gave us an advantage. COVID is, in a way, the first test for how the world should behave to comply with measures for environmental issues. We feel that, in the next 10 years, taxes on the carbon footprint and similar environmental markers, will influence businesses and will drive us in the direction in which COVID has already brought us. In a way, this has been a prelude to how we should keep working in the future – to favor video calls over travels unless it’s absolutely necessary, and to support local production. We will otherwise be channeled in this direction by various taxes.

Mihu: How do your customers perceive working remotely, one year in?

Theo Lammers: Working this way is progressing very smoothly because they could not do anything else. Before COVID, maybe 20% of people used video calls, and now everybody is doing it. The upside? The sky has never been this clean.

Mihu: Because such a landmark anniversary is an opportunity to look not only into the past but also towards the future, what are the next steps for KAAK?

Theo Lammers: What we learned from our experience with COVID is that we can do more from a distance than before. In the past, when an issue occurred, we would get a team of four-five people to travel and work on solving the issue on-site. Now, we send in cameras instead and try to solve everything at a distance. Our last smoking room was repurposed into a ‘cockpit’ from where we support lines remotely. Last year, we even started a line in Kenya from Terborg, with just a small team physically on location. The entire process was safe and the operational costs were significantly lower. This will continue in the future, with more software, more electronics, more IoT, and data know-how to help. We developed a platform, I-Bakecare, that gets data from our lines to analyze the mechanical and electrical performance and the process at the same time. This is also how our R&D is supporting our customer base with process improvements on anything from energy to product quality.

We are also focusing on servitization to answer requests from our customers so they can focus on their core business instead of managing the technology on the line for maintenance. This will be a driver for KAAK in the future.

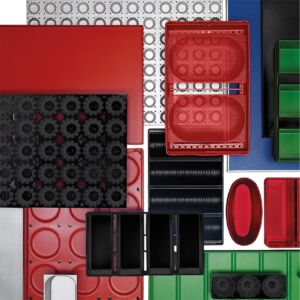

Bakeware is still part of our core business, in addition to developments in coatings in France, based on new technologies.

Lodewijk van der Borg: We try to approach our business in terms of SDGs (sustainable development goals). We adopted six to contribute in a positive way to our world: feeding the world is among them, which we try to do with our products, and diversity inclusion – our goal is to provide all our

employees worldwide with a safe environment. Sustainability is high on our priority list, managing carbon footprints, as we try to make our lines as energy-efficient as possible utilizing IoT, but also ‘greener’ logistics. For example, we try to get local specialists involved in projects to minimize traveling.

One of the main items we are developing to fulfill these goals are electrical ovens; we have invested heavily in this area over the past few years. In the past, a baker and a windmill were one – to mill the grains and start baking. We emphasize that we would like to return to using a windmill again – this time, for electricity instead of milling for sustainability.

Dough preparation is another area we are focusing on and provide to the market.

Mihu: What are the criteria guiding R&D at KAAK, when developing new solutions?

Theo Lammers: Energy efficiency for our proofers and our ovens is an important aspect. And sustainability of the materials we use is a priority. Looking at our bakeware, for example, we are always looking for new coating possibilities to minimize wear and tear and their impact on the environment. Of course, our developments have to always benefit our customers to lower production costs.

Lodewijk van der Borg: Hygiene is also an important issue, and this is where automatization helps greatly. In the context of sustainability, for example, we developed a 3D-printed knife blade that doesn’t get dirty while cutting dough. This saves a significant amount of production time and prevents product loss.

Mihu: How is the Group combining the joint efforts of its companies?

Lodewijk van der Borg: Every company has its own profit and loss records, but also its unique role in the products we market. Between the two, they each need to get a percentage of standalone sales. For example, if our bakeware is not able to sell standalone products anymore, we know the product is not competitive enough – and this is valid for all our equipment ranges.

Theo Lammers: We combine all the know-how within the Group. Every company has its sales, engineering, production and service departments, but we have also organized ourselves in a matrix – all our facilities have their service departments, for example, but we oversee all these service organizations, to combine these teams, learn from best practices, and set a standard. We do that for service, for operations, for sales, engineering, for product management, and also for development. R&D is centralized: we work on new developments with a dedicated R&D team.

Mihu: Looking at turnkey solutions beyond their installations, how are these projects coordinated between the Group’s companies?

Theo Lammers: Good question. We centralized turnkey projects here, in Terborg, where KAAK is based. KAAK is the biggest company in the group, and it specializes in spirals and proofers, robots and vision systems – but it also has the role of the integrator. Here, we have the project managers handling integrated projects, engineers who make the concept of the whole line and gather the information from the companies. The customers see the benefits in this way of working, as they eliminate any risks they would meet in putting lines together themselves. We have several interesting lines in Germany, for example, for which Benier provided the dough preparation components; proofers, robots, and handling solutions are coming from Terborg, the ovens come from Italy, trays and carriers are supplied by KAAK Bakeware, knives by K3D, and the electrical integration is done by Terborg’s team. This is presented to the customers as one quote from one big company with all its members supplying parts of it. We take responsibility for all the connections between various parts, which brings added value to customers.

Mihu: How is KAAK celebrating this important milestone this year?

Lodewijk van der Borg: On June 24, we will introduce our new logo and our new names to the world. We have all kinds of local activities planned within the companies, and, on November 5, assuming that COVID is no longer an issue, we are organizing a festivity here in Terborg.

Mihu: What will the future bring? And what will drive innovation?

Lodewijk van der Borg: Quality, safety and price will drive innovation. Bread will continue to sell. Wheat is the most sustainable choice in the long run, compared with rice, for example, which needs 10 times more water for cultivation. What’s more, global warming has made it impossible to grow rice anymore, in some areas. Industrialized production will increase by necessity. COVID has proven that, even when things go dramatically wrong in this world, the baking industry is quite vivid and needed – a very sound feeling for all of us, towards the future.

Mihu: Thank you very much for our dialogue, and congratulations on the anniversary!