With over 8,000 new patisserie product launches every year, the challenge for industrial bakers is to diversify their offers by developing innovative creations that also pass nutritional checkpoints and provide an exciting eating experience, through an efficient manufacturing process.

Patisserie products may represent only 6% of the bakery market in volume but they represent 22% in value. Equipment is essential in supporting efficient production and high product quality over a diverse range of specialties. Flexible lines can accommodate a generous product variety, with a wide range of customization options to choose from for various steps (e.g., filling, cutting, or decorating). Patisserie lines can be flexible at every step of the process, considering that the recipe has its own requirements. For example, various mixing techniques are needed to obtain doughs and batters with different characteristics, to ensure ingredients are hydrated or dissolved, evenly distributed, or aerated – requiring different tools and mixing settings. The same goes for batter dosing or dough depositing on the trays and for the key step to perfecting the product, baking. Each step contributes to the quality of these delicate products. In addition, efficiency is a requirement along the line, to optimize industrial performance.

In a recently published white paper on industrial patisserie, MECATHERM outlined ‘The three commandments of baking industrial patisserie products’:

1. ‘Produce your perfect patisserie product’ – All variables pertaining to the baking process need to be controlled and synchronized to support the simultaneous development of complex physical, chemical and biochemical transformations. Baking tools able to ensure accuracy are required. Some products are particularly challenging and are unforgiving to deviation from precise parameters; lava cakes are such an example of a complex product, firm on the outside, with a creamy heart.

2. ‘Be more flexible’ – Modular ovens, with independently configurable baking zones, can flexibly manage different baking curves across a wide range of patisserie product.

3. ‘Control your consistency’ – Automation can help optimize consistency in production. The benefit of having industrial ovens with a huge baking surface brings its own challenges, too: controlling the airflow is key to obtaining uniform products, regardless of where they are placed inside the oven. To achieve this, homogenous hot air circulation within the oven’s zones must be ensured.

All in one: the MECAPATISSERIE line

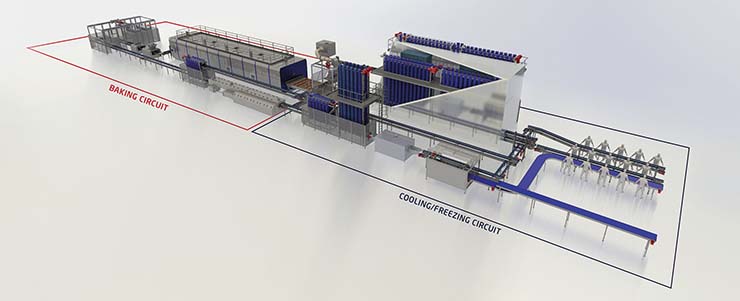

The French company’s answer to all these production challenges is the MECAPATISSERIE line, designed to produce a wide range of patisserie products, simple or complex, fresh or frozen, in multiple configurations.

At the heart of this system is the M-TA oven, MECATHERM’s latest, award-winning oven technology, in itself a flexible machine, equipped with compact, independent heating modules reaching up to 25 sqm. Each zone features six different baking modes. Moreover, its patented mobile system can double the energy transfer modes available on the top and on the bottom of the baking chamber, with convection technology (air streams) and/or radiation. Each baking zone has a dedicated steam injection system. These heat transfer modes allow bakers to establish tailor-made baking curves.

Marie Laisne, Product Marketing Manager for Ovens, explains: “The R&D teams have worked on the oven’s reactivity for its temperature to adapt very rapidly and precisely when changeovers happen. The use of a specially created highly modulating burner, as well as the rate of air renewal being extremely high, allow rapid raises and drops in temperature.” Computerassisted flow simulations contributed to the oven’s precision over flexible baking settings, as they helped to define and redimension the airflow circuits, to obtain a homogenous flow throughout the width of the oven. In addition, especially noteworthy in current circumstances, the M-Ta is an energy-efficient oven: its entry and exit zones are completely integrated to reduce heat loss, and the process accuracy and fast changeovers contribute to reducing energy consumption.

The MECAPATISSERIE line also incorporates an MVD cooler, including a buffer system, and an MVS freezer with dual infeed, to be able to receive products coming from the line while still available as standalone equipment. Depanning solutions can work with several types of tools, such as needles, vacuum, or fingers. Additional equipment can be integrated upstream, for mixing and dosing, downstream for packaging, or for personalization at any stage of the process. Production management tools are also incorporated: the M-Plan simulates and optimizes production scenarios to obtain the best line availability rate and the shortest changeover times, with the M-Pilot interface facilitating operation, production monitoring and traceability on the line.

How to innovate: cake texture

Experts at Puratos and MECATHERM worked together on perfecting cake texture, step by step. In a live stream event, they focused on working with two of the eight textures developed by Puratos: cream textures (‘Panda’ cake) and castella textures (‘Passion goes nuts’ castella cake). Participants received samples of each, to experience a tasting session with the experts. During each stage of the baking process (expansion, stabilization and coloring), the heat transfer method also influences the product’s characteristics, MECATHERM specialists explained. The Panda cake is round, with a hole on the top meant to be filled, and a flat bottom to contain the filling, with a golden-brown external coloration and homogeneous texture with no crust. The impact of different heat transfer modes was analyzed: with 100% radiant heat, the baking time needed to be increased, as there was not enough energy for the product; with 100% convection, there was too much energy, which impacted the cake’s shape. To obtain the desired result, “We mixed convection and radiant heat with adjusted intensities

inside each of the zones of the Mecatherm M-TA oven. The precise baking parameters of this oven allowed the texture, shape and coloration of the product to be controlled,” explained Marie Laisne.

Starting from each texture, they demonstrated how bakers can expand and develop new creations; setting the different baking profiles available on MECATHERM’s ovens helps support the process. Further customization with fillings or toppings provides even more unique selling points for patisserie products.