As the highly-anticipated Baking Expo is approaching, exhibitors are preparing their stands to once again welcome visitors to the trade fair in Las Vegas. We asked some of the industry’s big players for a glimpse into the novelties we can expect. Here are some of the stands worth exploring, listed by booth numbers.

Booth 209 – EnSight

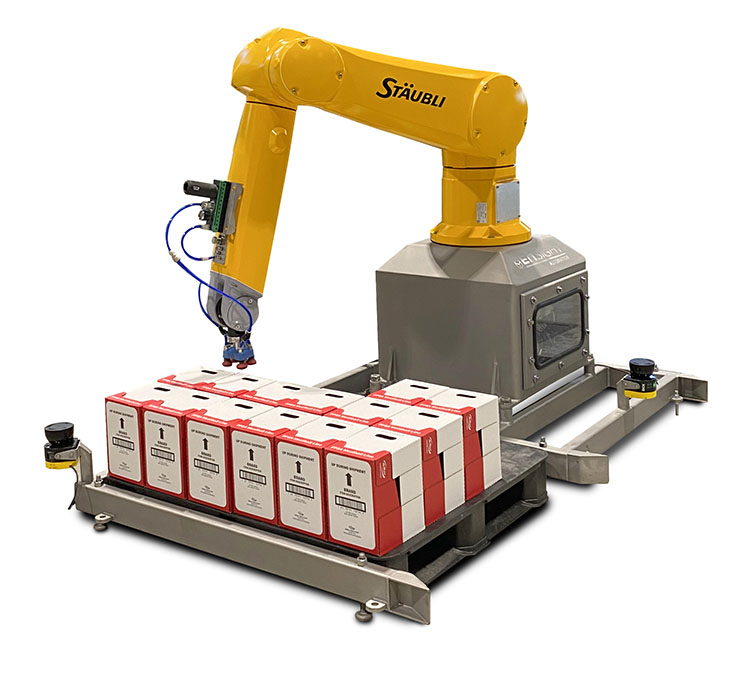

EnSight is presenting its heavy capacity Fenceless palletizing in a washdown environment, high-shear mixing equipment – Likwifier (formally Breddo Likwifier) – batch mixers, jacketed, icing systems, and Inline mixers for continuous applications. Among new developments, a Stäubli TX2-160HE hygienic robot is featured, with wash-down properties and area scanners that will make it slow down and come to a stop when an operator enters the work area. “This allows us to fit the palletizer in smaller areas that couldn’t usually fit palletizing,” EnSight explains. The Stäubli robot can lift up to 75 pounds of product at a time. A new, more hygienically designed frame for high-shear mixers will also be highlighted.

Booth 301 – FRITSCH

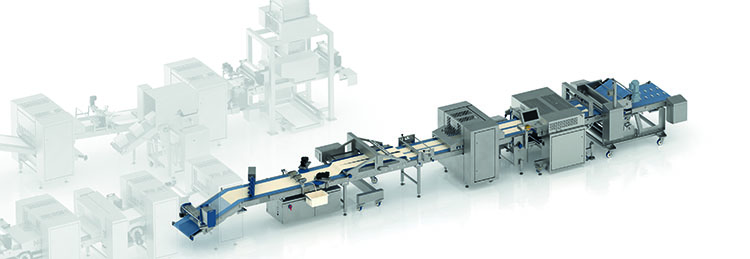

FRITSCH will introduce the new ROLLFIX 3.0, the DOUGHLINER, the MULTIVAC R 105 Thermoforming packaging machine with printing and inspection, and the new compact bread line, the PROGRESSA bread – shown virtually by popular demand.

Launched earlier this year, the PROGRESSA bread was designed for easy accessibility with toolless parts removal and no motors, sensors, or other electrical components in the drive compartment of the line for quick and thorough cleaning with a steam jet. Two weighing units, ensures weight accuracy throughout the entire process. The compact bread line also features our new SDS nano, adapted from the FRITSCH industrial line dough sheeter, which applies flour to the dough sheet from all sides. “Complete flour-dusting means no need for oil, greater precision in dough production, and faster cleaning. Once dusted, the dough sheet transfers from the SDS nano to the FRITSCH Soft Dough Roller (SDR) for gentle rolling, producing a highly uniform dough sheet, free of shearing forces and separating agents,” FRITSCH explains.

Booth 725 –

Tecnopool SPA

Tecnopool is promoting innovative solutions together with those of their sister companies Gostol and Tecnofryer. TP5 is a newly-designed spiral belt for Tecnopool’s spiral systems. An improved design of Gostol’s TP-N cyclothermic oven will also be highlighted, as well as TEC, a family of tailor-made industrial frying systems, and Gostol’s ‘Smart Bakery Line’ portal. Tecnopool, Gostol and Tecnofryer can offer machines and lines to answer the production requirements of virtually any type of baked good, devising highly automated, flexible, and economical industrial solutions for medium and large-sized bakeries.

Booth 1001 – VMI

VMI will be exhibiting its range of mixing equipment at IBIE: vertical, planetary and continuous mixers. The company is also introducing its Virtual Reality Area, using technology to transport the user into an immersive experience to discover mixing systems that integrate several mixers and automate the progression of batches from one station to another. Attendees will be able to walk through a full-size batch mixing system to understand the process and capture how it will perform in reality. “As our product range includes specific configurations to meet manufacturers’ needs, VR enables visitors to experience large automated systems free from physical constraints,” VMI explains.

VMI’s latest planetary mixer will be showcased, the Phebus mixer. It has a bowl capacity of 200 liters and features an ergonomic and easy handling design, with a hygienic, stainless-steel design. “This mixer excels in the most complex preparations, including creams, sticky doughs, batters and specialty breads,” VMI explains.

VMI is also promoting its ability to design custom solutions to each industrial challenge, with various mixing technologies adapted to ingredients, process, and location constraints.

Booth 1033 –

Koenig Bakery Systems

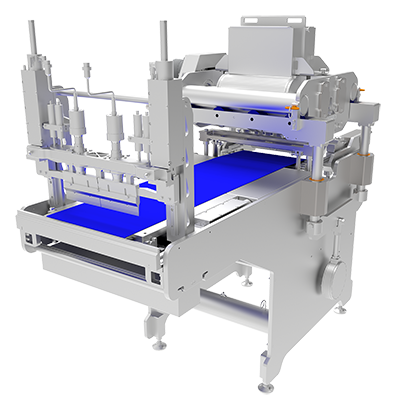

Koenig is introducing its new I-Rex Compact Easy Clean (EC) machine at the trade show. It incorporates the I-Rex Compact EC Divider and Rounder – a machine with a completely redesigned structure. “The head machine only has one load-bearing end shield, the one on the drive side. The possibility of opening the cover of this head machine on three sides offers the user the best possible accessibility for cleaning and maintenance,” Koenig explains. All relevant components can also be removed on the operator’s side.

It has a weight range from 1 to 7 oz (30 to 200 g) – addressing small and medium as well as industrial bakeries. The new machine combines very compact dimensions with an industrial performance of 14,400 pcs/h at 40 strokes/min.

Booth 1201 – Diosna

Diosna will focus on equipment flexibility, showcasing the DIOSNA Wendel Mixer WH 240 “A” of the Hygienic Design series. The design of the mixer is based on the high standards and guidelines of the European Hygienic Engineering & Design Group (EHEDG), Diosna explains. This mixer combines high-performance mixing with open stainless steel construction for easy cleaning, allowing mixing bowls to be quickly changed for an efficient succession of batches and a fast switch between different recipes. Surfaces are hygienically optimized to prevent microbial and particulate contamination of the baked product. It can be upgraded to a fully automatic system by adding a transport system.

Booth 1267 – HEUFT Thermo Oel GmbH & Co. KG

HEUFT provides premium oven solutions made in Germany for medium-sized artisan and industrial bakeries. At IBIE, the company will highlight its large oven systems, with reduced CO2 emissions, and its thermal oil technology. “Our large oven systems are custom-made, therefore each piece is an innovation itself. Our ovens are not only maximally flexible but also highly cost-efficient when it comes to energy savings,” HEUFT details. All ovens use thermal oil as a heat transfer medium, as it is a champion in heat conduction.

A patent-pending innovation is the hybrid thermal oil heater, which heats thermal oil sustainably and provides the freedom to choose the energy source. It combines two technologies: an electric and a fired heater. The electric heater can use electricity from regenerative sources, the fired heater, in turn, can use natural gas or heating oil as an energy source.

Booth 1601 – Dawn Foods

Dawn Foods will highlight several solutions, including:

+ Trends & Insights, with the company’s highly anticipated 2023 global trends on customer behaviors and macro industry influencers. To develop these insights, Dawn collected data across dozens of syndicated sources, conducted proprietary research, and observed customers and consumers firsthand across various channels and regions globally. Sarah Hickey, Senior Director of

Insights & Market Research at Dawn Foods, will unveil these trends at a speaker session at IBIE on Saturday, Sept. 17.

+ Digital advancements: Dawn will demonstrate how its eCommerce platform benefits bakeries.

+ Top Products presented onsite will include sourdough and brioche donuts, vegan and cleaner label bakery mixes, fillings, icings and glazes; varieties of cake donut flavors; Dawn Exceptional® E-Z Open™ Flat Icings; Bakery Essentials by Dawn® – a comprehensive portfolio of bakery ingredients and supplies; new product previews.

Booth 2024 – Kwik Lok

Kwik Lok will bring to IBIE its Eco-Lok, Fibre-Lok, and the New Closing Line of the Future. Eco-Lok and Fibre-Lok can be used with existing Kwik Lok automatic bag closings.

The Eco-Lok is a great solution for bakeries that are looking to reduce carbon and plastics. It is made with up to 20% renewably-sourced starches. Fibre-Lok is a 0% plastics solution that is made with cellulose fibers. “In some places, it may be home compostable and/or provisionally recyclable depending on the infrastructure available,” Kwik Lok details.

The packaging company has recently updated ‘Closing Line of the Future’ which includes Kwik Lok’s 893 closing machine bundled with its tamper-evident 909 laster stitch machine and the newest fiber laser print technology. Both Eco-Lok and Fibre-Lok are designed to work with this line.

Booth 2131 – ABI Ltd.

ABI will be showcasing its automation solutions, robotic scoring system, and vision system platform. A robotic scoring system will give live demonstrations at the show. Waterjet technology is the latest addition to the scoring options they offer. Now bakeries can choose from conventional, ultrasonic, or waterjet cutting. ABI will also share the innovative vision platform they recently developed specifically for the bakery industry that addresses many gaps found in the conventional vision systems. This system is the company’s latest innovation, designed to collect, compile, and analyze multiple image sources in real-time. It provides high precision and consistency for many ABI robotic solutions.

Booth 2131 – MECATHERM

MECATHERM will highlight the M-Care, a new digital solution helping industrial bakers to optimize their performance. Live demonstrations will be organized to showcase its features. Accessible with a smartphone or tablet, M-Care is an innovative intuitive interface enabling to identify drifts, prevent breakdowns and machine failures, and provide comfort and simplicity to operators and maintenance teams for first-level maintenance operations. Most of the new MECATHERM ovens are M-Care ready. From vertical ovens to flexible production lines, MECATHERM will also explain how their solutions enable industrial bakers to face the market challenges in terms of product quality, industrial performance and sustainability.

Launched at IBIE in 2019, the smart and responsive MECAFLEX line will return. It incorporates the flexible M-TA tunnel oven and the M-UB handling system, for a large range of products, produced using different process combinations with trays of varied types and formats. The M-TA oven offers multiple heat transfer modes, such as convection or radiant heat, or a combination of both in each independent heating zone. The M-UB handling system has been designed to be adaptable and flexible, whatever the product type, production volumes and constraints imposed by industrial.

Booth 2625 –

Bundy Baking Solutions

Bundy Baking Solutions will feature its latest innovations including new American Pan ePAN designs for bread tin sets and the AccuTech Pan Greaser from its newest brand, Synova. The new ePAN designs are up to 30% lighter than other pans and have allowed bakeries to save energy by decreasing oven temperatures and gas usage. The new greaser design features many improvements to application accuracy and sanitation and maintenance procedures. The company will also be highlighting its proprietary release agent formulas, new eRack designs, custom sheet pan capabilities and their exclusive pan coatings and comprehensive services.

Booth 2645 – Rademaker

Rademaker intends to reacquaint visitors with its portfolio of solutions. A product showcase will take center place – all products made with Rademaker machines around the world are available for sampling. Equipment will also be highlighted: a three-section Radini Laminator and Make-Up line will be displayed. “They are perfect for the small to mid-sized wholesale baker looking to automate their production. Our latest sheeting solution for artisan bread features the updated DSS for the most gentle process of the highest quality ciabattas, baguettes, and batards,” Rademaker details.

Innovation should be expected at this stand, with robotics, virtual reality, product scanning, Academy Training, and Systems Integration.

Booth 2971 – IPCO

IPCO will be using this year’s IBIE to highlight four key areas:

+ Solid and perforated steel conveyor belts – “The key qualities of an IPCO bake oven belt include outstanding thermal properties for efficient baking; the inherent ease of cleaning of a belt compared with mesh; and the attractive return on investment when considering the overall lifetime cost.”

+ A comprehensive range of conveyor components: IPCO can also support OEMs in system design and supply a full range of conveyor equipment, from sheaves and shafts to bearings and breakpoints. Other ancillary equipment available includes active and passive belt alignment solutions such as belt edge detectors, guide rollers and compact/automatic tracking devices

+ Global service support, with sales and service offices in more than 30 countries. IPCO can deliver inspection and maintenance services that go beyond the belt, with investigations encompassing the entire line to understand how the system as a whole is performing.

+ Chocolate forming systems: systems designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms and many more. The company will be demonstrating a fully operational Rotoform chocolate forming system at IBIE. This is a high-capacity rotary drop depositor that can be used to form chips of different sizes – from 30,000 to 300 pcs/kg.

Booth 3008 – Ashworth

Ashworth is expanding on the success of its Smart Spiral monitoring system by introducing the Smart Oven monitoring system. It monitors critical oven operating parameters and provides real-time feedback to maintenance, engineering and plant management, alerting of out-of-tolerance conditions. It offers a graphical representation of the collected data, which authorized personnel can access on a mobile phone, tablet, or personal computer. This graphical data will show current and past operating data, compiling a trend analysis that could indicate pending system issues. By anticipating system failures on time, repairs can be planned and performed before system failures occur.

Booths 3425, 3435 – Reading Bakery Systems

RBS will feature new snack systems and technologies at IBIE:

+ Multi-Crisp System – this flexible system produces baked crisps from a variety of different doughs. “This flexible system is perfect for making “healthier-for-you” snacks, including the newest product – the pita chip,” RBS says.

+ Advanced WCX Wirecut Machine – this machine can create the widest variety of cookies including multi-color dough, filled cookies and bars and encapsulated cookies.

+ Ovens of the Future – Sustainability is a big initiative at RBS, with efforts specifically focused on ovens. “Learn about our electric oven options and how we are ‘Baking for a Better Tomorrow’,”RBS invites.

+ Automated Continuous Mixing – The RBS Exact Mixing booth (3435) will feature automated continuous mixing systems that cut costs by reducing labor, energy and mixing errors, while improving consistency and simplifying your entire mixing process. Among them is new Hydobond instant hydration technology. “Now more than ever, with the labor, energy and cost-containment issues, automation is the key to future success,” says RBS.

Booths 3435, 3601, 3625, 3801, 3825 – AMF Bakery Systems

AMF Bakery Systems is bringing a comprehensive suite of solutions to its stands. Among them, the company highlights its digitalization and sustainability roadmap for bakeries. “<Illuminating the lights-out bakery> is part of our booths at IBIE, showing solutions and equipment that work 24/7,” AMF anticipates. Sustainability and digitalization are hot topics that are reflected in products and services that will be showcased: sustainable ovens (e.g. hydrogen, electric and hybrid models of the Den Boer Multibake), the Sustainable Oven Service, with managed services by AMF Den Boer to save gas and get optimal oven management support from AMF’s oven consultants, and the Smart Applicator (used for strewing materials, weight and distribution management). AMF Tromp will display the latest sheeted Breadline for artisan bread, ciabatta, baguettes and other breads.

Booth 4471 – MIWE

MIWE will highlight a wide range of baking oven technology, ranging from all-around deck ovens for artisan baking and in-store usage, to rack ovens and flexible solutions, combining deck and convection ovens on a small footprint. MIWE will also be exhibiting bakery refrigeration solutions such as the fully automatic proofing unit MIWE GVA.

Two different rack ovens will be showcased at the MIWE booth at IBIE, focusing on the MIWE roll-in e+ in its newest version. “It is a rack oven for bakers valuing efficiency, consistency, quality and energy efficiency with new functions for wider product variety, better servicing and new connectivity features,” MIWE explains. The MIWE roll-in stands out with several innovative features, especially for industrial and semi-industrial bakers. In addition, MIWE will exhibit the rack oven MIWE orbit, the choice for small and large bakehouses and market bakeries.

The all-rounder MIWE condo deck oven will also be presented: electrically heated, with a gentle baking atmosphere; it can be used for a wide range of products, from pastries to bake-rolls, or artisan bread. The MIWE backcombi combines convection and deck for maximum flexibility on a very small footprint. It is ideal for small(er) shops and bakers. MIWE econo completes the lineup – a convection oven suitable for point-of-sale baking, ideal for parbaked goods.

Booth 4613 – Sugden

Sugden highlights its new insulation system, developed for the company’s English Muffin production lines. Belgium waffle lines will also be promoted, to meet the interest for this product on the US market.

For the English Muffin Lines, Sugden has developed a three-layer insulation. With the two rigid boards on the outside and a special product in-between, temperatures of 250°C were reached on the inside, while on the outside, it doesn’t go above 35°C. This insulation protects all the components of the burner system and ensures they are operating well within their upper-temperature limits. “It is a huge step forward to lower the running costs of the production line,” Erik Smink explains. This insulation will be available on all Sugden’s product lines, new or refurbished.

The Belgian Waffle production lines are constantly fine-tuned for products in capacities up to 20,000 pcs./hr.

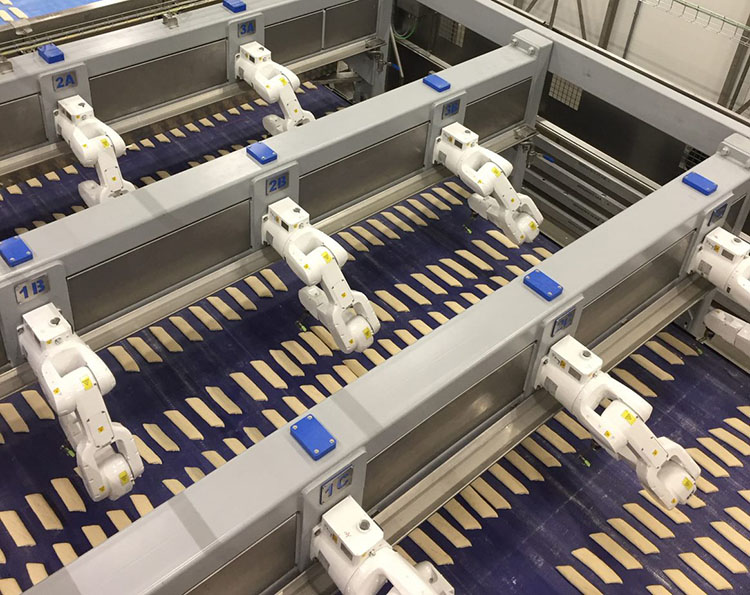

Booth 6571 – Royal KAAK

KAAK will present process automation solutions aiming at reducing labor costs and manual labor dependency, improving hygiene, reducing fallout, and improving product consistency at the highest quality. New innovations that will be showcased at the trade show include robotic dough scoring solutions, using different scoring tools: water jet, rotating knives, and perforated metal scalpels with airflow. A pizza pressing solution, on a belt and in a pan, is also among the novelties to be presented at the stand. Integrated production lines with uniform software control should also be noted among the highlights.

Royal KAAK is focusing its expertise on the manufacturing of pizza, hearth and artisanal bread, baguettes, buns and rolls, and tin bread.

Booth 7255 – Stäubli

Stäubli will be presenting the HE version of its TX2 robotics series for sensitive food applications that require fast kinematics that can withstand wash-down and temperature changes. The TS2 SCARA industrial robot will also be presented, winner of the prestigious Red Dot Product Design Award 2021.

On display will be the hygienic, fully encapsulated TX2-90 HE, which has a reach of 1,000 mm and will feature ultrasonic cutting as well as showcase an automated wash-down process. It features connections through the base of the robot, no retention areas, complete protective coating and internal pressurization of the arm, as well as a H1 lubrication option.

The award-winning TS2-80 will illustrate a vision, tracking and packaging application. The completely redesigned 4-axis machine with proprietary JCS drive technology facilitates ultra-short cycle times and high repeatability. It also has an encapsulated design, for hygiene standards required in the food industry