Several methods can be used for depanning baked products safely. Automation provides the next-level tools for maximum flexibility and reliability. The good news is that it does not require replacing a whole line to incorporate.

Depanning is traditionally performed with methods including inline conveyorized solutions and gantry systems. These depanning stations can be retrofitted with robotics, which comes with multiple benefits.

While they have some limitations, inline depanning systems are effective in performing a basic continuous movement, lifting the product with the vacuum heads of the conveyor and depositing it onto another conveyor. They do so by using a vacuum belt that runs atop the pan conveyors, in the direction of travel. As trays pass underneath the vacuum conveyor, suction is engaged, drawing the product out of the pan and adhering it to the vacuum belt. While it is very efficient in terms of space utilization and overall line design, this method can only be used for a limited variety of products that match the positioning of the vacuum cups and can be easily lifted from their pans, such as baguettes in perforated fluted pans. In addition, inline systems can only be adopted where the layout allows for the product to continue straight on after depanning.

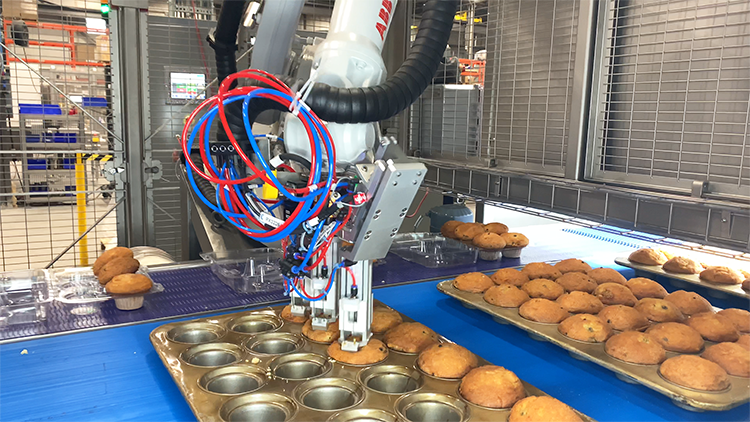

In addition, gantry depanning systems are typically used for products that are not easily handled by the more traditional inline systems. The suction cups are arranged to match the layout of the pan. “For example, muffins that are baked in individual cavities of a large pan will have fixed spacing and require an individualized picking and handling approach for optimal placement following depanning,” ABI Ltd illustrates. The gantry moves the product from the pan to the product conveyor. The pick-up location, movement path, and drop-off location are dependent on the bakery layout and are fixed, once determined. “However, gantry systems offer the additional flexibility of providing three planes of movement – X, Y and Z axis (forward/back, side to side and up and down), where Inline systems are limited to running with the existing direction of pan and product travel. They can also be set up in parallel with the pan conveyor and can use a broader range of tooling, including suction or needles.

Needle tools are frequently used for products that are heavily seeded, to mitigate the risk of removing the seeds, which is an inherent risk with vacuum tooling. They can also be used for depanning sweet goods like pound cakes, as they provide a means to establish a much firmer grip on the product during depanning and flight. Using tool changers, operators can efficiently swap tools to match a variety of products and pans.

Depanning with robotics

Robotics can be installed on existing lines, used for a diverse range of products (including loaf breads, buns, cakes, cupcakes, or muffins) and replacing a depanning system is not required. ABI states that it can create custom tools and solutions for a large range of bakery products, with both conventional and robotic solutions.

Robots bring the maximum degree of flexibility to the table, regarding possible movements and tooling options. An automatic tool changer allows the depanning system to switch between a wide variety of different end-of-arm tools (EOATs), safely and efficiently.

Robots bring added benefits in addition to conventional depanning solutions in several key areas, starting with their location and orientation. ABI explains: “There is such a broad selection of robots to choose from that you can hang Delta robots over a line, place a six-axis robotic arm atop and parallel to the product travel for expanded reach and diverse approach paths, or place SCARA robots adjacent to the line for high speed, repetitive picks and places… The variations are endless.”

In addition, robots can perform complex movements, beyond the capabilities of gantry and inline systems – especially robots operating on a six-axis movement. For example, if products need to be depanned into a container, these robots can approach the container at an entirely different angle and orientation than the one used to pick the product.

Robots are also consistently accurate, compared with traditional systems. They can run at varying speeds, depending on their type and the way they are mounted. Moreover, they tend to require less maintenance than any other type of automation. “If the right type and number of robots are deployed and the load is managed correctly, robots have an extremely long life, with very wide Mean Time Between Failures (MTBF) windows.

The right tools

Different options that can be used for tooling include suction, needles, soft or hard mechanically-actuated gripping tools, soft or hard air-actuated gripping tools, or scoops of varying configurations. ABI details:

+ Suction cups use vacuum to lift the product from the pan. Depending on the type, size and weight of the product, various styles are used. Products can be lifted with a single cup, or by combining several cups into a particular pattern. Releasing the product into the downstream process involves either a quick vacuum release mechanism or supplying low-pressure compressed air into the suction cup.

+ Needle grippers are a set of thin needles that are inserted into a product to form an ‘X’. The robotic arm lifts the product out of the pan and moves it to the desired location. Then, the needles retract and release the product.

+ The grippers are similar to the touch of human fingers: during the pick, the dual durometer ‘finger’ is inflated, causing the finger to curl around the product with a predetermined pressure. Strategically positioned fingers, in a pattern best suited to the product, allow for gentle but firm handling of the product. For product release, the air is extracted from the finger cavity, causing the finger to flex outwards.

In addition, scoop tools with shapes (such as spatulas, or spoons) can be used to take the products out of a range of different types of pans. In this case, the release is typically carried out by flipping or quickly pulling away, which causes the product to drop. This method is not very precise, which is why it is not widely adopted.

New developments

The Canadian company has recently developed several upgrades for its robotics-automated depanning systems. ABI has shortened changeover times down to seconds, while manual switchovers may take several minutes. This is done through the use of interchangeable tool mountings and automated tool-changing setups. “With automated tool changing in particular, the robotic arm automatically goes into its changeover position and releases the attached tool. It then moves to a secondary position, attaches to a tool in waiting and travels to its home or cycle start position, ready to begin operation,” ABI explains. These changeovers are entirely automated, without the need for an operator.

ABI’s robotics-powered depanning technology also features an enhanced vision system, which accurately locates the product being manipulated. Robots use vision systems to guide their operation – from locating and correctly identifying the products, to performing QA by comparing them to predefined parameters. “Previously, a pan and all the product in or on it would need to be perfectly positioned for depanning, but with our improved vision system, we can accommodate variability in pan positioning and still depan the product with precision,” ABI LTD elaborates.

The company has also built a broader range of custom EOATs that support unique requirements for products with different densities, textures and surfaces. The variety of pans that bakeries use was also taken into consideration when developing these tools.

With the new vision system, some configurations allow the use of a quality control function: sub-standard products can be automatically rejected by programming robots to only pick out the products that passed inspection. “This type of feature can be used as a means to gather important performance data and also to improve overall process efficiency at the line,” ABI specialists explain. Robots programmed this way will not waste cycles and resources on products that will be discarded.

The robotic systems, together with the vision platform, can collect a vast array of data on productivity for analytics. They can provide insights into the depanned and rejected products, production rate statistics and other KPIs.

Efficiency rules

To optimize efficiency when using a depanning system by ABI, a good release from the pan is at the core of the priorities and the appropriate method for the type of product. The technology specialist also recommends the optimum placement of the system relative to the production line and the bakery’s layout. Pans should also be in a good condition, to support efficient depanning. “Configurations are largely dependent on a customer’s needs, the type of product, and the existing layout. We custom design our systems to ensure depanning is done with optimum efficiently,” ABI explains.

Options can include parallel, perpendicular, or inline conveyors – with one conveyor above another. They can travel in the same direction or opposite directions. Other features can include full pan depanning, single cavity depanning, or multiple cavity depanning.

Different types of pans can be used with these depanning systems and, respectively, various product ranges and production volumes. The selection of the robotic depanning process will be designed according to the product and the desired processes downstream (e.g., depositing on a cooling conveyor or a packaging container). Multiple products can be picked with a single moving sequence. ABI adds: “Product volume capacity is generally just a factor of limitation per robot; solutions can be scaled accordingly to meet throughput requirements.” Multi-pick tooling helps to keep the number of robots lower, while providing higher overall throughput capability.

To ensure product integrity through the depanning process, testing is a vital step in ABI LTD’s installation work, to ensure the goods remain intact. “Each product requires an individual approach,” the technology specialist explains. “Choosing the depanning method and designing the EOAT to the product specifically allows us to make considerations about the product’s unique traits. For example, when choosing the vacuum depanning method, air volume and pressure are customized for the product. For needle depanning, the number of needles, entry points and angles of penetration can be customized to match the product. With grippers, the number of contact points and their configuration are among the factors that contribute to optimizing hold and stability.

The range of depanning speeds vary significantly and are dependent on many conditions, including the layout, type of product and the type of pans. The ABI team works with bakeries to identify suitable production rates for their needs.