By Dr. Julien Huen, ttz Bremerhaven

Resource scarcity is affecting nearly all sectors of the economy worldwide, with the baking industry being no exception. The massively increased energy prices are currently the main concern for bakeries, but recurring shortages of raw materials and personnel are making the situation worse. This article aims at describing the current issues of resource scarcity and proposes solutions – mainly in the technical field – to tackle the crisis.

It is very legitimate to expect political solutions from governments, yet companies must also check what they can do to adapt their business models to the new conditions. The current megatrends in consumer demand should not be put out of sight.

The COVID pandemic, the war in Ukraine and climate change are global events with massive consequences on the availability of resources, especially in the agricultural and food sectors. Bakery companies are facing a series of acute challenges that need to be addressed rapidly. Ideally, the adaptations performed should not only consider the short-term situation but rather be part of a strategy that places the companies in a favorable situation for the future.

Energy costs

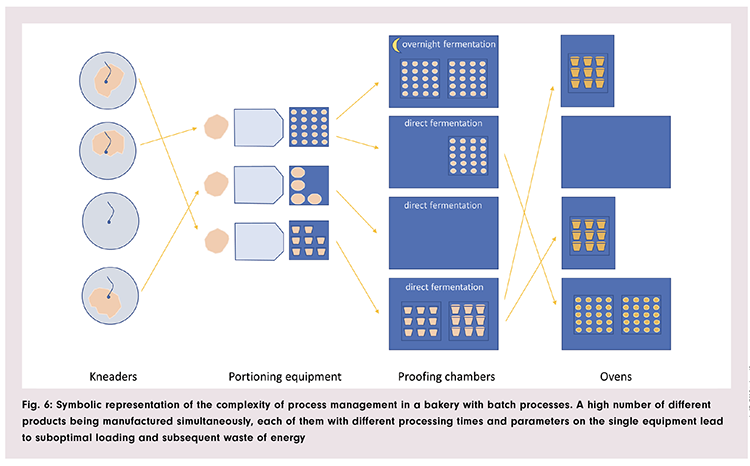

The production of baked goods is a very energy-intensive activity that implies especially mechanical and thermal processing steps. The most common energy sources in the bakery industry are electricity for mechanical processes and cooling, and gas for heating. Both energy sources are currently going through dramatic price increases (figure 1). In addition, shortages of both energy sources are not excluded in the coming winter.

How high is energy consumption actually in the baking business? It has been estimated that bread-making companies spend between 1,5 and 6 kWh for the transformation of 1 kg of wheat flour (so-called ‘specific energy consumption’), with a strong dependency on the size of the company: production sites processing higher amounts of flour have, on average, much better energy efficiency.

It is interesting to compare these figures with the enthalpy of some basic physical phenomena taking place during bakery processes: the gelatinization of starch contained in 1 kg of wheat flour consumes 0,002 kWh, the denaturation of protein contained in 1 kg of wheat flour consumes 0,00015 kWh, the evaporation of 200 g of water (typical bake loss in relation to 1 kg of flour) 0,12 kWh. Heating 1,65 kg of dough (typical dough quantity obtained from 1 kg of flour) from 25 to 100°C needs 0,1 kWh, and freezing 1,65 kg of bread dough from 25 to -20°C consumes 0,12 kWh. This makes it clear that the main part of energy spent in bakeries does not actually reach the product, but rather is lost in the process or used in the concomitant activities.

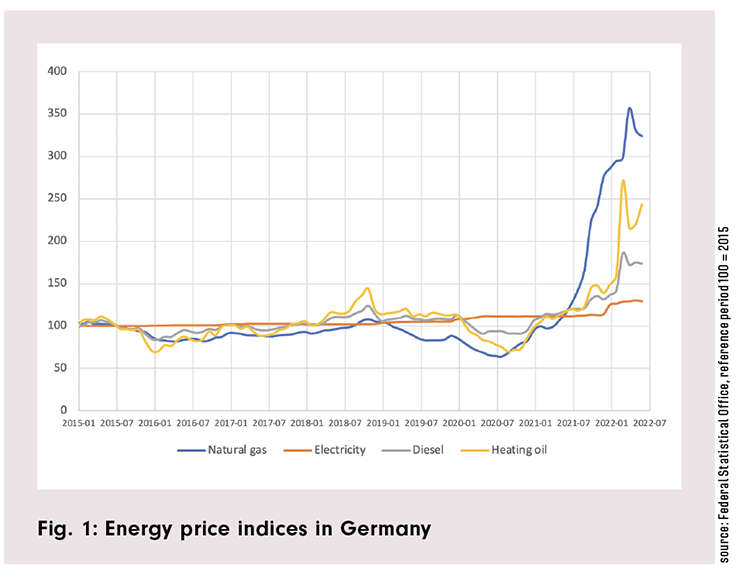

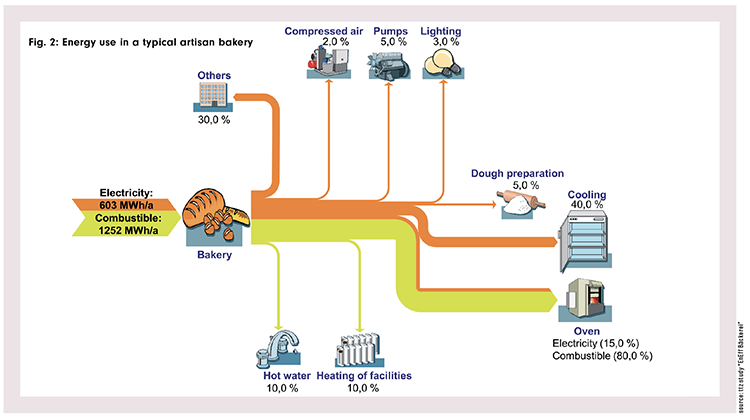

Figure 2 shows that heating and cooling are the main processes consuming energy. During baking, it is estimated that only 36% of the energy reaches the product (Figure 3).

Therefore, addressing energy scarcity will include reflecting on which energy sources are being used, where energy losses can be reduced and whether product/process concepts can be rethought, to minimize energy consumption.

Raw materials scarcity

The shortage of raw materials may have different causes, including (1) actual reduction of the quantities available on the market (nearly non-existent export of wheat and sunflower from Ukraine, of palm oil from Indonesia; reduced harvests following extreme weather conditions), (2) logistic difficulties in global supply chains, (3) ‘panic buying’ from some market stakeholders (as recently in the case of dry yeast) and (4) competition with non-food applications like biofuel production.

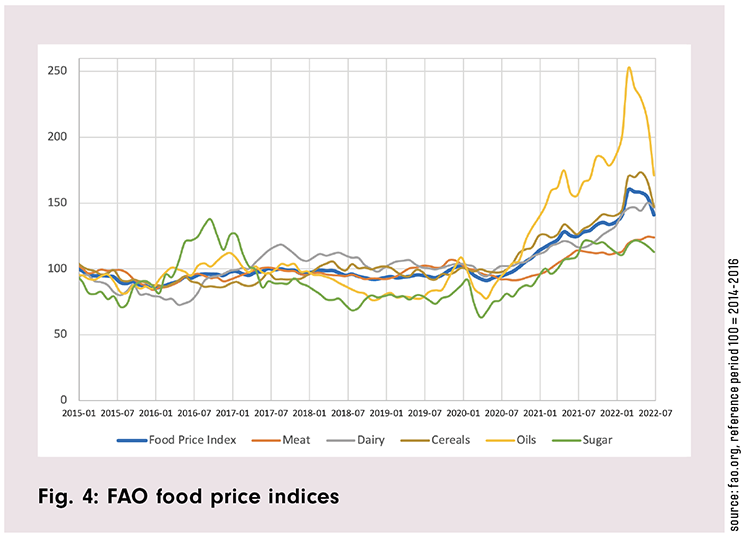

Figure 4 shows the price evolution of foodstuff on the global market: since the beginning of 2020, high volatility with a clear upwards trend is observed with about +50% for cereals and +80% for vegetable oils.

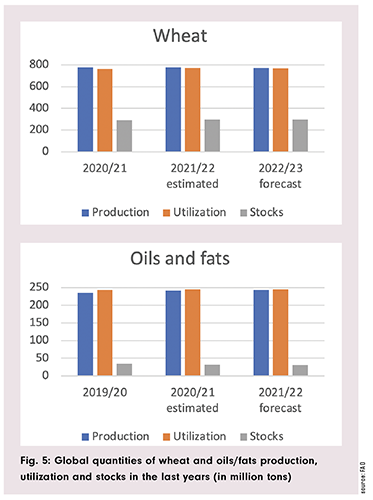

It is to be noted that, from a global point of view, there has been no significant change in the balance between production and consumption since 2020, as FAO data show (figure 5). Local shortages are, therefore, mainly a problem of distribution. Consequently, price increases are mainly related to local shortages, increasing energy costs and speculation.

In the case of wheat, the EU is in a favorable situation with an annual production (approx. 125 million tons) clearly exceeding its consumption (approx. 100 million tons). In contrast, countries that are net importers and with low capita income experience strong difficulties: Lebanon is currently not able to satisfy its domestic market demand and Egypt has decided to increase the amount of bran in refined wheat flour to 6% to compensate for the price increases.

It is difficult to predict the impact of climate change on future global harvest quantities and quality. Studies suggest that, in some places, a warmer climate may lead to higher yields. Alternatively, climate change will also result in more frequent drought episodes and other extreme weather conditions that compromise harvests. In addition, increasing land degradation leads to a decrease in the total amount of cultivable surfaces. It is reasonable to expect at least an increasing variability of the raw material quality due to changing climatic conditions.

Staff shortage

While the bakery business has been suffering from difficulties in attracting qualified staff for years, the situation has further worsened since the beginning of the COVID pandemic. Difficult working times, low wages, physically demanding working conditions and an image of backwardness are reasons for employees increasingly turning to other business fields in a tight job market.

Megatrends in consumer demand

While the availability of resources is decreasing, the consumers’ expectations do not stop evolving. Therefore, adaptation strategies should take both the resource and the customer side into account. Current changes in consumer demand target the use of ingredients from local farming and processing, nutritional/health quality, plant-based, clean label and low environmental impact. In addition, in the context of global inflation and decreasing spending capacity, some consumers may look increasingly for products in the low-price segment.

Solutions

Due to such dramatic changes in market conditions, bakery companies can hardly continue running their business in the way they used to: either the resources or the customer demand would be missing. In this context, we would like to propose some approaches for tackling the described challenges (see table 1). Our focus lies on solutions that may be implemented by the companies themselves. Political interventions that aim at regulating energy prices, preventing insolvency of businesses and supporting consumption, are not being considered.

Of course, each business situation is unique. Choosing the appropriate combination of measures is a highly strategic decision and should reflect the genuine identity of the company. Some of the described solutions address specifically one resource, whereas others target improving the overall resource efficiency. Some solutions consider only the resource side, while others also involve the modified consumer demand.

Simplification

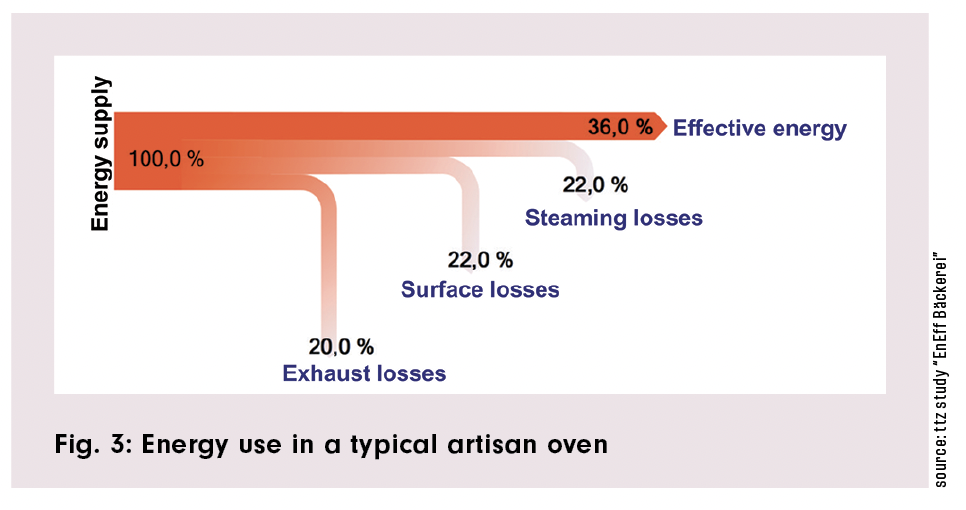

The simplification approach is based on the general assumption that complex processes lead to a decrease in efficiency and a waste of resources. How can this be applied to bakery production? It can easily be conceived that automated industrial continuous lines on which one single product is running for several days without interruption allow for very high efficiency in terms of personnel, raw material and energy resources. Switching from one product to the next always implies downtimes, material losses and workload. In artisan bakeries, the daily production of a high number of fresh products with batch processes is essentially less efficient (see figure 6). At the same time, this means that artisan bakeries have the highest potential for improvement in resource usage.

Applied to the product range, the simplification approach implies finding out which core products are mainly responsible for the success of the company and represent its identity best. Eliminating products that do not match these criteria will improve overall productivity. If needed, complementary products may be sourced externally.

A further step concerns the recipes, following the trend of clean labels and striving for a reduction of the total number of ingredients and additives in use. This will decrease the dependence upon specific raw materials and lower the resources needed for sourcing and storing the ingredients. Some functionalities may be replaced by the development of process know-how, like the use of sourdough. Removing raw materials with stabilizing functionality may reduce the degree of standardization of the products. It must be evaluated whether consumers are ready to accept this higher variability, which may be the case if the clean label concept is well communicated.