All information is valuable information in the realm of inspecting products throughout the entire manufacturing process, through to packaging. Automated inspection systems are able to guarantee top product quality and safety – no exceptions allowed

By Yuegang Zhao, Chief Commercial Officer, KPM Analytics

In-line vision inspection technologies comprehensively inspect 100% of the products throughout the entire manufacturing process. This can be achieved with two types of systems: Vision Process Control systems (VPC) and Final Product Inspection systems (FPI).

Vision inspection was initially developed for FPI systems applications to verify final products for visual traits and brand standards before packaging. While these technologies streamline inspection by taking and analyzing objective measurements, baking companies now have several options to deployvision inspection to help them close the loop on quality control. VPC systems can be installed at key production process stages – before or after baking. Using multiple VPC systems makes it possible to monitor different production phases in real-time and, if necessary, fix issues causing non-compliant products, minimizing waste and ensuring product safety, with no exception.

Combining VPC with FPI means total control of the manufacturing process is available, with the tandem of systems providing actionable data and an overview of the process capabilities of the production facility. This is a step toward a smart factory environment.

Integrating vision systems

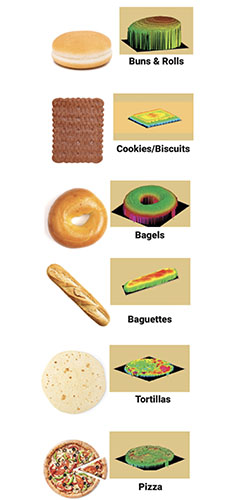

Every baking operation is unique. Similarly, vision inspection integration is an iterative process that will uniquely match each respective setup. For companies considering vision inspection in their operation, the best route is to begin focusing on the most critical individual traits of the most important products in the production portfolio. It may be the baked color of a type of cookie, the uniform diameter or height of a bagel, or the distribution of toast marks on a tortilla; whatever those one or two features may be, this is where to begin the journey.

It is also essential to engage the Quality Assurance and production teams early and often through the integration process. Aligning everyone’s expectations will contribute to the development of a solution that suits all the operation’s specific needs. This leads to the design of a vision inspection solution with reasonable tolerances for quality and consistency.

“Combining VPC with FPI means greater control of the manufacturing process is available, with the tandem of systems providing actionable data and an overview of the process capabilities of the production facility. This is a step toward a smart factory environment. ”

Yuegang Zhao, Chief Commercial Officer, KPM Analytics

Camera configurations are among the details established based on specific production needs. There are several factors that contribute to selecting the most beneficial camera configurations, including whether it takes 2D vs 3D measurement, the camera itself (its resolution), and its placement – whether it is a top vs bottom camera, or installed in parallel across the conveyor belt. The choice of camera configurations is optimized for cost and performance for each production line.

Rejection mechanisms are also uniquely set up around the production environment. When selecting the best sorting/rejection technology to pair with a vision inspection system, there are several important considerations that should be factored into the evaluation. These include the physical properties of the products being inspected, the operating speed (e.g., throughput) of the production line, the production line configuration, material handling requirements and compliance reporting requirements.

In some cases, the value of a rejected non-conforming product may recommend re-processing the item, rather than directly discarding it. In such cases, the redirection system can be used in place of a rejection system to re-route the flagged product for secondary inspection or other processing. For example, when dealing with small or lightweight baked goods, air jets installed above or to the side of the product are one method to isolate or redistribute products, based on their measurements. Larger items may need a servo-driven paddle, a pusher system, or other product-specific rejection method.

Each vision inspection system can also come with its own visual dashboard that can be displayed on a large display above the production floor, or virtually so that it can be accessed anywhere within the plant. The dashboard displays real-time production information such as the number of products inspected, yield, uptime, etc.

Another frequently used optional feature is having a lane balancing system after the final product inspection. For certain products such as bagels, the lane balancing

system helps optimize the flow of the product before entering the packaging machine, to prevent jamming and improve productivity.

The EyePro Q-Bake Vision Inspection Systems from KPM Analytics are specifically tailored for high-volume baking operations to maximize productivity, optimize the inspection process and reduce waste. Each system is installed directly onto the production line to measure products for various visual traits, including 2D/3D height, bake color, shape, length and width. Moreover, other detailed measurements can also be made, such as the inclusion coverage (chocolate chips, seeds, etc.), the product shine, and foreign object detection.

Q-Bake systems feature product-specific software that takes into account all the predefined measurements of interest for the specific product. Users can set the limits of tolerance for each measurement and add new measurements whenever necessary.

The root cause

Once vision inspection systems are in place, the next step in production efficiency is to investigate the root causes of the defects and how to minimize them. This requires bakers to go upstream in the production line and inspect dough and flour properties according to their production recipe. Some bakeries are even exploring new uses for vision inspection technology in combination with their flour and dough analysis efforts.

Rheological instruments can be incorporated in this effort, to quickly analyze incoming flour from millers and suppliers. One such rheological instrument is the Mixolab 2, a universal dough characterizer that measures the constraints flour goes through from the mixing process to baking, providing comprehensive information on protein, starch, improvers, enzymes, and all interactions among them. Mixolab 2 helps to provide ‘acceptance curves’ for flour quality based on these analyzed parameters.

Vision inspection aids in the creation of these quality standards by verifying product appearance at various process stages. By matching the final baked product outcome from a baking test against the analysis curve from Mixolab 2, bakers can more accurately assess whether a new flour delivery will adapt to produce the desired final product.