Margarine has been a key ingredient in fine pastries for decades, with dedicated products being offered for nearly every single application. An interesting contender is analyzed for its opportunities in baking: liquid oil.

By Frida Köning, ttz Bremerhaven

Over the last few years, manufacturers have been increasingly questioning the status quo and testing liquid oil in as a substitution in their recipes, according to CSM Ingredients observations. This motivated a joint team, with specialists from CSM Ingredients and ttz Bremerhaven, to have a fresh look at the topic and perform its own comparative investigations into the functionality of baking margarine vs. liquid oil in selected applications.

From the theoretical point of view, vegetable oil – after refining – is a liquid product with a fat content of almost 100%. Margarine, on the other hand, is a water-in-oil emulsion with a fat content of at least 80%, which is solid at room temperature. Usually, both phases contain further components. In addition to oil, the fat phase consists of solid fat (e.g. palm or coconut), emulsifiers (e.g. mono- and diglycerides), colorants (e.g. β-carotene), flavorings, antioxidants (e.g. α-Tocopherol) and sometimes other fat-soluble vitamins (e.g. vitamins A, D). In addition to water, the water phase usually contains table salt and acids (e.g. citric acid).

On the basis of these different compositions, hypotheses can be formulated for the expected effects of margarine on baked goods compared to liquid oil: the use of solid fats, which are partially crystalline at room temperature, may result in a firmer consistency of the doughs/batters and the pastries. Crystalline fat is more tightly enclosed in the structure of the pastry, which may release less fat to fingers or packaging. Due to the crystalline fat structures with different light refraction than liquid oil, the pastry may appear brighter. The use of colorants such as β-carotene counteracts this phenomenon. When pastries with margarine are eaten, the fat crystals melt in the mouth. This endothermic melting process may cause a ‘freshness’ sensation. The use of flavors may create a more complex flavor profile that can be perceived with our senses. The perception of the flavors may be enhanced by the salt in the margarine. The use of emulsifiers may stabilize the structures in the dough and may ensure greater pastry volume, more homogeneous structures and a finer pore appearance.

To investigate the original question and the above hypotheses empirically, a series of tests were carried out at the ttz Bremerhaven in which three different products were baked with both margarine and a refined oil (fat equivalent +80% water) and compared with each other. The selected baked goods were sandwich bread (~ 5% fat), brioche (~ 10% fat) and pound cake (~ 20% fat). The solid fat used for the sandwich and brioche was Meister Goldback margarine (CSM Deutschland GmbH) and for the pound cake Meister Goldcreme margarine (CSM Deutschland GmbH). The refined oil was rapeseed oil (Power Oil Rostock GmbH). The evaluation was made with respect to the sensorial and physical performance differences of the final products.

Characterization of the final products was performed by Volscan (Stable Micro Systems Ltd) for the determination of the specific volume, C-Cell (Calibre Control International Ltd) in order to analyze the crumb structure and Texture Analyser (Stable Micro Systems Ltd, TA-HD plus) for the measurement of the crumb texture concerning hardness and springiness. In terms of sensory evaluation, a simple descriptive assessment was completed for all products.

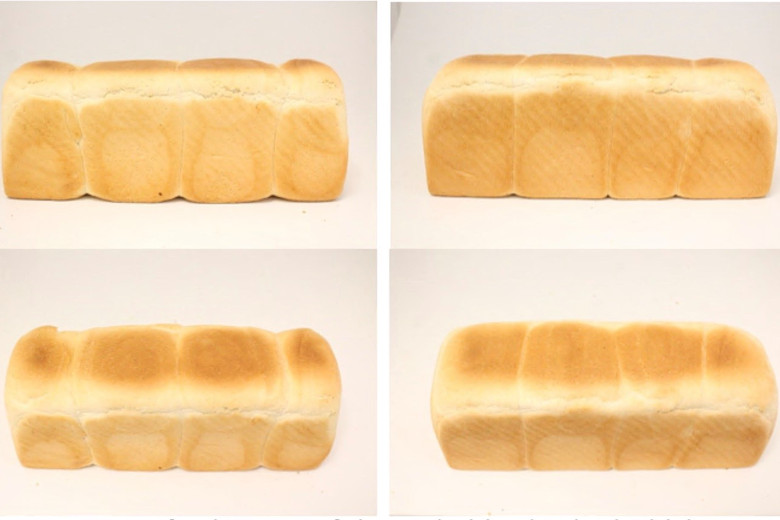

Sandwich bread

Both the sandwich breads with baking margarine and the sandwich breads with refined rapeseed oil had a good appearance after proofing and baking and filled the baking tins properly. They were described with a typical wheat bread flavor and taste. The mouthfeel was perceived as pleasantly soft, not chewy and succulent. The crust was golden brown and the crumb was even and fine-pored. Concerning the samples with rapeseed oil, the tendency pointed towards a slightly thinner and softer crust, especially towards the bottom of the bread. Furthermore, one test person noted a slight inherent odor also reflected in the taste. (Figure 1)

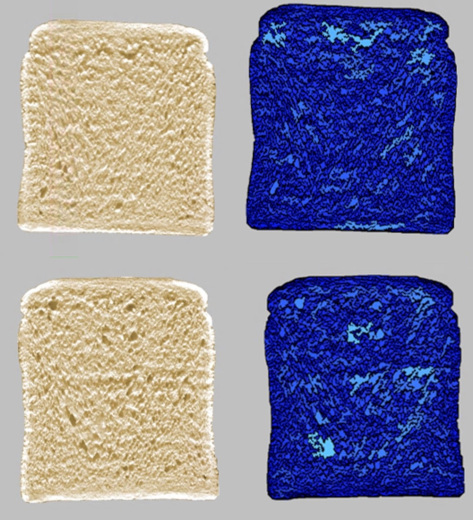

With the C-Cell, the sensorial impressions were confirmed by a comparable number of cells per area and on average less than one hole per slice for both recipes. Furthermore, a significantly higher slice brightness for the sandwich bread with baking margarine was measured. The cause for this phenomenon may lie in a difference of the refraction of the actual dough possibly due to the crystalline structure of the margarine or less deep cells of the crumb. Checking the cell volume confirms a tendency (not significant) of smaller cells. (Figure 2)

The analysis of the crumb texture measured with a Texture Analyzer revealed a significantly firmer crumb with baking margarine. The springiness was similar for both sandwich breads. Both crumbs reached more than 80% of their original height after the application of force.

All in all, in the evaluation of the sandwich breads with a fat content of approximately 5 %, hardly any differences were found between the products with baking margarine and with refined rapeseed oil.

Brioche

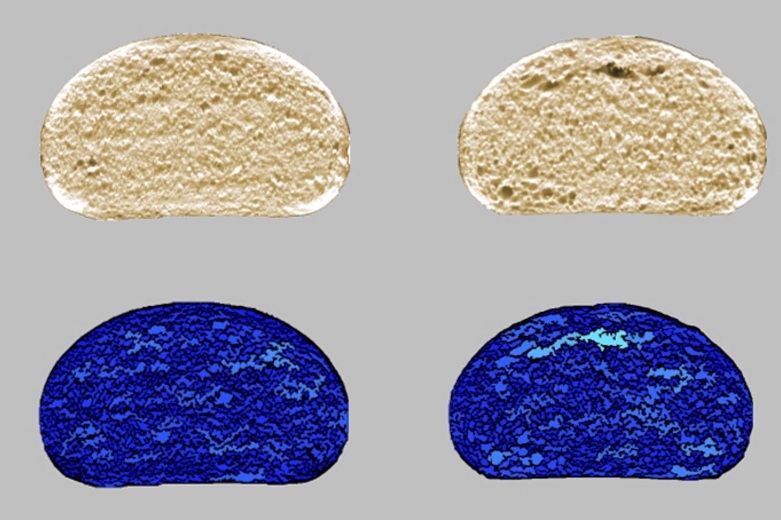

The comparison of the brioche produced with baking margarine and with refined rapeseed oil revealed obvious differences in the outer appearance. While the crust of the brioche with baking margarine was characterized by a golden-brown, smooth and even surface, the crust of the brioche with refined rapeseed oil was darker and softer with blistering of the surface. In accordance with the blistered crust, the volume measurement revealed a consistently greater specific volume for the brioche recipe with refined rapeseed oil compared to baking margarine.

The overall impression of both crumbs also differed. While the crumb with baking margarine appeared fine and uniform, the poring of the samples with refined rapeseed oil was perceived to be more irregular and coarser with a tendency towards detachment of crust and crumb. With the C-Cell, a slightly higher number of cells per area (significant) could also be measured in the samples with baking margarine, indicating a finer poring. In addition, a significantly smaller cell volume was determined. Both are also reflected in an overall higher slice brightness. A detachment of the crumb was only detected in individual samples with refined rapeseed oil. Overall, a comparable number of crumb defects in the form of larger-than-average pores/ holes was detected. (Figure 4)

Furthermore, the texture analysis of the brioche revealed that the application of the different types of fat influenced the hardness and the springiness of the crumb significantly. The brioche crumb containing the baking margarine was firmer and less elastic than the crumb with refined rapeseed oil. The latter matches with the impression of a tougher behavior when tearing the roll apart during the sensorial analysis. Nevertheless, a more elastic crumb is associated with better performance when it is buttered with a knife. If crumbs are too elastic, this may lead to the issue of a spongy mouthfeel. In the sensory evaluation, both brioches were described as sweet and typical yeast-based pastry products with a pleasant mouthfeel. In direct comparison, the brioche with refined rapeseed oil smelled a little less fresh, but the mouthfeel was a little more succulent/slightly less dry.

All in all, the comparison of brioche with a fat content of 10% produced with baking margarine and with refined rapeseed oil revealed differences, especially in the outer appearance, and also in the texture of the crumb.

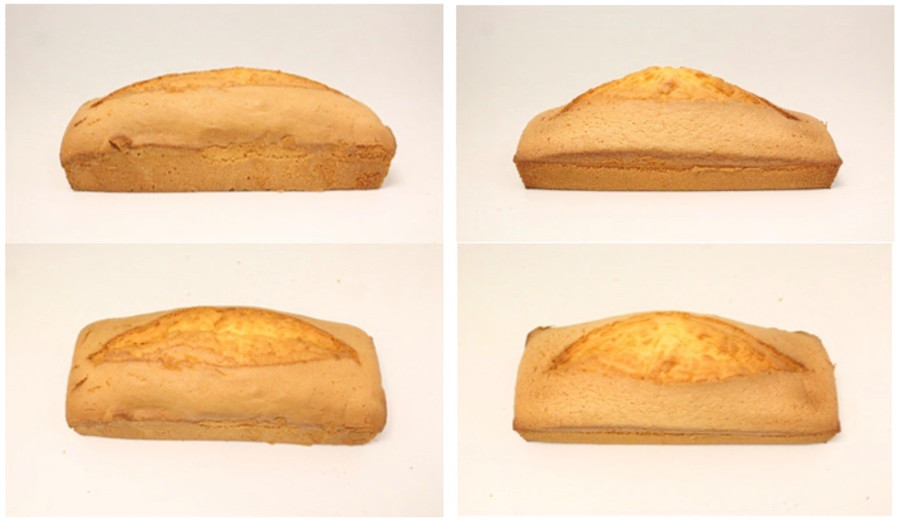

During the manufacturing process of the pound cake, two completely different batters resulted. While the batter with baking margarine was very airy and creamy, the batter with refined rapeseed oil had a more liquid appearance.

After the baking process, on one side, a cake with baking margarine had an even appearance, a smooth, shiny surface and an optimum crust crack. On the other side, with refined rapeseed oil, the cake surface appears significantly less shiny, rougher and more porous. (Figure 6)

Nevertheless, analysis of the crumb structure by C-Cell showed that there was no significant difference in the number of cells per area or holes. However, a significantly larger cell volume and a significantly lighter crumb were measured for the cake with baking margarine. At this point, a small effect of the margarine, which was added to the cake at 20%, on the color of the dough is inferred.

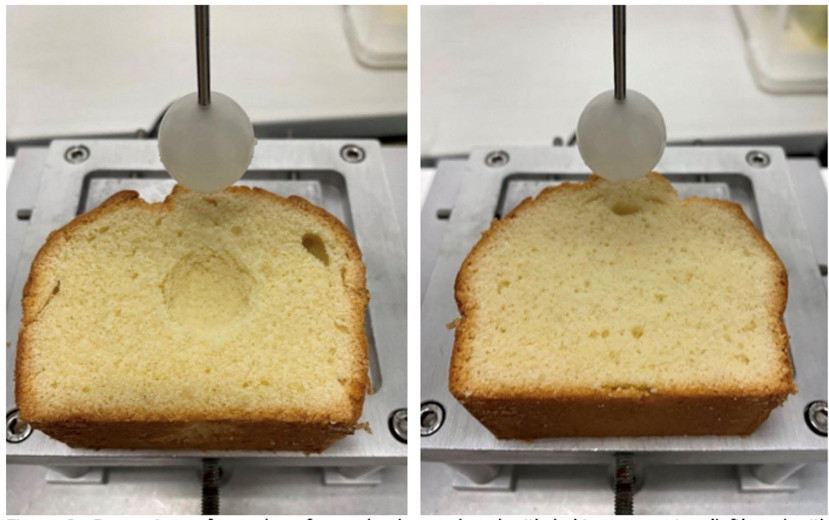

Sensorially, both cakes were described as sweet, typical lemon cakes. The pound cake with baking margarine was perceived as more aromatic/flavored and buttery. In terms of mouthfeel, the pound cake with baking margarine was soft and fluffy, but also crumbly, while the sand cake with refined rapeseed oil was firmer, more elastic and oilier, which was also reflected by an oily film on the fingers. Although a comparable firmness of both crumbs was measured with the Texture Analyzer, it could also be determined that the crumb of the cake with refined rapeseed oil was almost twice as elastic as the crumb of the cake with baking margarine. This result aligns perfectly with the sensory impression of the pound cake with baking margarine being crumbly and the pound cake with refined rapeseed oil behaving spongy. This behavior is also captured by a picture of a sample of each product right after the texture analysis. (Figure 8)

The most striking differences were seen in the baking tests with baking margarine and refined rapeseed oil in the pound cake with a fat content of almost 20%. In summary, the results show that in the production of pound cake, the choice of fat used is clearly reflected in the properties of the baked product.

Reflecting on all results generated in the scope of this research project leads to the conclusion that the kind of fat (baking margarine vs. refined rapeseed oil) used for bakery applications does make a difference in the performance of the product. It seems that the intensity of the effect is product-dependent. While little to no effect was identified for the sandwich bread, a more noticeable effect was measured for the brioche and the most intense effect appeared for the pound cake. It can be assumed that these observations are related to the fat content of the products. The sandwich bread only had a fat content of approximately 5%, while the fat content of the brioche was set to 10% and the pound cake reached a fat content of almost 20%. Most significant was the effect of a higher springiness of the crumb by the use of refined rapeseed oil. On the contrary, this means the application of baking margarine is accompanied by a reduced springiness. The possible explanation lies in the physical state of the fat. While the refined rapeseed oil is liquid at room temperature, the margarine is partially solid due to the crystalline state of some fat components. Even though the margarine melts during the baking process, it recrystallizes in the final product at room temperature, resulting in a less elastic crumb on one hand, but also a less spongy mouthfeel on the other (especially so for pound cakes).

Furthermore, the use of baking margarine in the conducted tests has a positive effect with regard to the common expectations on the external appearance of the product. The brioche as well as the pound cake made with refined rapeseed oil was characterized by an irregular and rough product surface, while the brioche and pound cake with baking margarine showed a smooth and shiny surface. Partially, effects on the pore structure of the crumb were identified. Here, the actual number of cells was influenced to a lesser extent, but rather the slice brightness reflected a combined impact in the number of cells, the average volume of the cells and the actual color of the product.

All in all, the research project successfully characterized the differences in bakery performance concerning the use of baking margarine compared to refined rapeseed oil. The existence of margarine for bakery applications finds justification, especially regarding the outer appearance of the products. Margarine and oil can be used for different structural adjustments. A joint application for the optimization of the target parameters is conceivable.

More baking trials based on additional products and the detailed characterization of the doughs and their properties are planned.

Cooperation: CSM Ingredients – ttz Bremerhaven

A two-year Science Cooperation Contract was signed in December 2021 between CSM Ingredients and the Technology Transfer Zentrum (ttz Bremerhaven).

CSM Ingredients is a manufacturer of ingredients with a broad portfolio of specialty fats, products for the manufacture of fine baked goods, bread and rolls, and food solutions for a wide range of industrial applications.

ttz Bremerhaven is an independent provider of research services and operates in the application-oriented field of research and development. The common aim is to explore new technologies in the areas of bakery, plant-based food, nutrition and metabolism, clean label and new functional ingredients. Therefore, joint innovation workshops are held and scientific experiments are conducted at the ttz Bremerhaven.

Photos: ttz Bremerhaven

Read the full article in Baking+Biscuit International, issue 1 -2023.