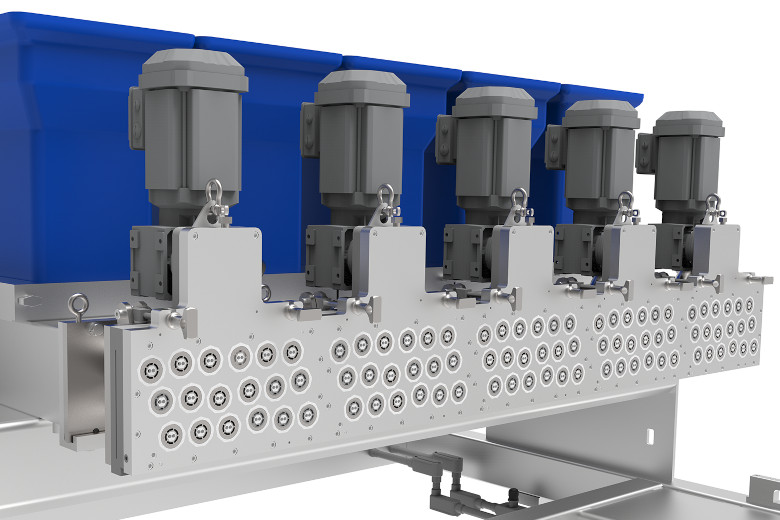

Reading Bakery Systems (RBS) designed a new 18-nozzle rotating die for increased throughput capacity. Depending on the size of the finished snack product, it increases throughput capacity by up to 33% on the same size production line when compared to the 12-nozzle die that has been available to the industry for 40 years, RBS details.

The rotating nozzle die creates wound shapes spirally while continuously extruding a rope of dough, which is then cut into twisted pretzel and stick products. The number of rotations made, and the speed of the extrusion can be controlled independently – to increase the range of product that can be made in terms of shapes and textures.

The new design has incorporated gear-driven nozzles constructed of stainless steel with internal nozzle inserts made of FDA-approved sanitary plastics. These new components utilize a food-grade semi-solid lubricant, instead of gear oil. The rotating nozzle die mounts directly onto all standard RBS low-pressure extruders, expanding these systems’ flexibility.

“We are excited to offer this new product offering to our customers looking to increase capacity or create new products. The twisted products are very popular because of their unique texture and ability to hold tasty seasonings,” said Nico Roesler, North American Pretzel & Snack Equipment Sales Manager.

Photo: Reading Bakery Systems