Different types of products made with laminated dough have their own process requirements to achieve the desired characteristics. Flexible equipment is needed to support variations and to do so efficiently, especially in industrial baking facilities.

Every type of dough and resulting product requires a specific laminating method. When laminating dough, fat layers can be shaped in different ways. Even distribution in the precise amount is key to perfecting this process, and therefore the best method for the product should be identified that best matches the product and its processing system. When making this choice, particular attention should be paid to evaluating the dough tensioning in the dough piece, especially on the sides of the slab. “We also look at the fat distribution in the base dough; the goal is that the fat layers are distributed as evenly as possible through the whole dough,” Rademaker’s specialists outline.

Jan Willen Jansen, sales technologist, and Henri in ‘t Veld, head of product management explain how Rademaker lines can support the three laminating methods developed by the company: horizontal, overlapping or by cutting and stacking layers. Laminators are set up according to the production volumes, the type of fat used, the number of layers needed for the products, the desired thickness of the layers and the dough reduction method. Rademaker’s laminators can produce dough sheets up to 512 layers. “Because all these build-up layers need to be reduced to the required dough thickness, the reduction process needs to be done very gently. If not, there is a big risk of damaging the layering structure, which leads to a non-acceptable product,” they explain. Going over 512 layers will almost not be visible in the product and would bring no benefits. The number of layers can easily be adjusted from the control screen. The production will automatically change to an adequate production speed. In the case of large adjustments, the reduction steps must also be closely examined, Rademaker recommends. Once the optimum settings have been found, they can be saved in the system so that they are available again for the next production run.

In addition, proofing systems are added where necessary, as well as a cooling and resting section – if the product requires this step: “To obtain the highest quality layers of dough, it may be necessary to cool and/or rest the dough sheets in a cooling and/or resting cabinet. Within the laminating process, the layers of dough and fat are essential for the baking structure of the final product,” they highlight. The type of fat (butter, margarine, shortening, low-trans or non-trans margarine) is determined by the type of product and the process which is best suited to it. Its influence on the taste is a consideration in this choice, in addition to price differences. The fat pump on the system can handle all options equally well. Choosing the solution that is the closest match to all manufacturing requirements is a collaborative effort. In co-development with its customers, Rademaker translate their wishes and requirements into “tailor-made laminating solutions and thus offers a range of croissant and pastry lines to shape the dough to any product desired,” the specialists add.

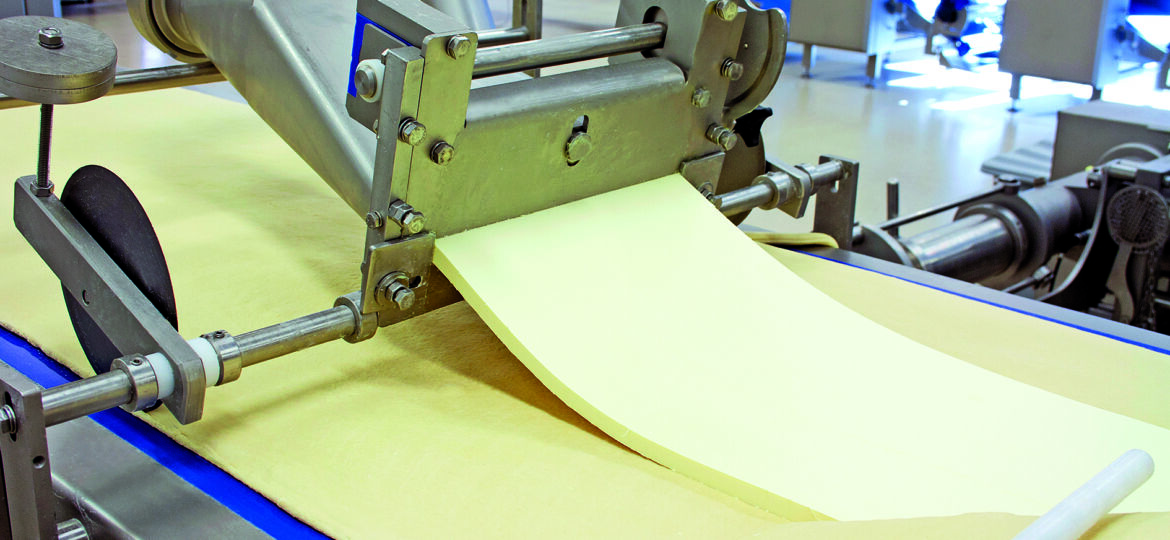

Laminators are adjusted to support the desired product in all aspects – from crumb, to shape and texture. For flexibility, they come in different working widths and a modular design, covering a wide range of capacities in its standard configurations. The layout can also be flexibly adjusted, with choices of shapes including L-, U-, and Z-formats. The design of Rademaker’s equipment also allows a good view of the dough flow as it is laminated, for a fast visual assessment of the process.

Efficiency in every layer

Precise control over the entire process is the key to increasing efficiency. The overall setup of the Rademaker Laminator is designed for high production efficiency and user-friendly operations. Its tools are easy to remove, the parts that need to be regularly changed are reduced to a minimumm and its scrapers are exchangeable. All these aspects result in minimal cleaning efforts and increase production uptime. Furthermore, the system is equipped with automatic settings allowing for a ‘one-button’ press to bring the entire machine to the perfect cleaning or drying status. After cleaning, the operator will be warned if belts are not tensioned properly, Rademaker says.

Process control by means of intensive data handling and communication is becoming increasingly more important in industrial production processes. “Our control platform enables OMAC based data exchange with neighboring (third party) equipment as well as LMS, MES or ERP systems,” the specialists explain. Furthermore, advanced data processing enables online monitoring and optimization of equipment efficiency. The smart use of the combined information regarding process and recipe allows easy and fast start-up of operations and optimizes flour usage. The existing cascade system and automatic belt speed adaption is an advanced control system. It features fully automatic speed adjustment and enables the different sections to operate independently. While the last section of the production line finishes processing, the first section of the line is ready for cleaning or to begin running another product. The operator will be prompted when the next recipe can be started on the machine. Moreover, the number of sensors the laminator uses is reduced, to guarantee optimal control with minimal risk of downtime due to malfunctions.

Downtime management Several aspects related to the equipment itself play a role in how often downtimes occur:

+ Cleaning: when not carried out correctly, the machine is more likely to come to a standstill because of contamination that can cause malfunctions in the process or the machine. To mitigate this, Rademaker machines are designed and developed to facilitate easy and thorough cleaning.

+ Maintenance: the design of the machine also plays an important role in the ease of performing maintenance, to ensure the wear parts are replaced on time and quickly, and that bearings maintain their lubrication levels, for example.

+ Skill: the experience of the operating staff often plays a major role in minimizing downtimes as well. “On the one hand, we try to make the operation of the machine as easy as possible, both mechanically and in terms of software/user interface. On the other hand, we have set up Rademaker Academy to educate personnel and bring them up to speed as quickly and efficiently as possible,” Rademaker details. With skilled operators running the line, problems that might occur will be handled and solved much sooner.

+ Tool changes: when frequent changes need to be made as different types of products run through the line, the ability to quickly change AND correctly set up production tools on the machine is of crucial importance to guarantee downtimes are minimal while also minimizing scrap that can result (incorrectly produced items) during start-up after a tool change. “The sophisticated design of our tool positioning and structural help from the user interface (via the ‘Tool Assistant’ menu) guarantee the lowest possible impact of changeover times,” the Rademaker specialists underline.

+ The sturdiness of mechanical and electrical components: the correct choice of materials and using high-end components will make operation predictable and make unexpected breakdowns unlikely.

In addition, external factors can also be responsible for production downtimes, particularly up- and down-stream processes, including mixing, proofing, freezing and baking. The correct supply of ingredients and product removal is a prerequisite for the optimal functioning of the entire production line. “The Rademaker System Integration department can compose a tailor-made production process for each specific customer demand. Here, a combination of ‘Best of Breed’ partners is selected to ensure uptime (and product quality),” they specify.

External environmental influences such as temperature and humidity, as well as the choice of ingredients and the composition of the recipes, can also disrupt the production process and can cause downtimes.

Maintenance innovations

The optimal balance between production, cleaning, maintenance and any tool changes can bring significant benefits. The planned downtime for tool changes has been reduced in some cases from one hour to less than 15 minutes. Similar improvements have also been achieved for cleaning and maintenance. Data gathered by the PLC can be used to improve maintenance (e.g. motor loadings, running stops and stop causes).

While service and maintenance requirements are reduced by optimal material selection, on the one hand, Rademaker laminators are designed to be easily accessible for service and maintenance, on the other hand. “This results in minimal wear and increased lifetime of all sensitive items, in combination with minimizing needs for spare parts. Lifetime-lubricated bearings in the product zone and clear, comprehensive lubrication locations for bearings outside the product zone consequently result in minimal downtime,” they highlight. Parts that require regular maintenance are located in easily accessible places and, importantly, located outside of the production zone. Furthermore, all conveyor belts are equipped with quick belt release mechanisms to reduce downtimes during cleaning and to keep maintenance to a minimum. All of this results in less time being required for cleaning and maintenance.

Additionally, Rademaker provides 24/7 service assistance for its customers. The Service department can also do preventive maintenance and/or make a list of necessary spare parts, to ensure that they are available in the bakery in case replacements are needed.