IPCO showcases its chocolate forming and molding equipment at interpack this year, with systems designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, or blossoms. Solutions can be customized for various operations, from start-up low-cost, rapid deployment equipment to high-capacity multi-layer systems.

“The main highlight will be on our flagship Rotoform system and we will have a fully operational unit on our stand. Rotoform is a rotary drop depositor that produces chips of highly uniform size and shape and is the foundation on which all of our capacity systems are built,” IPCO highlights.

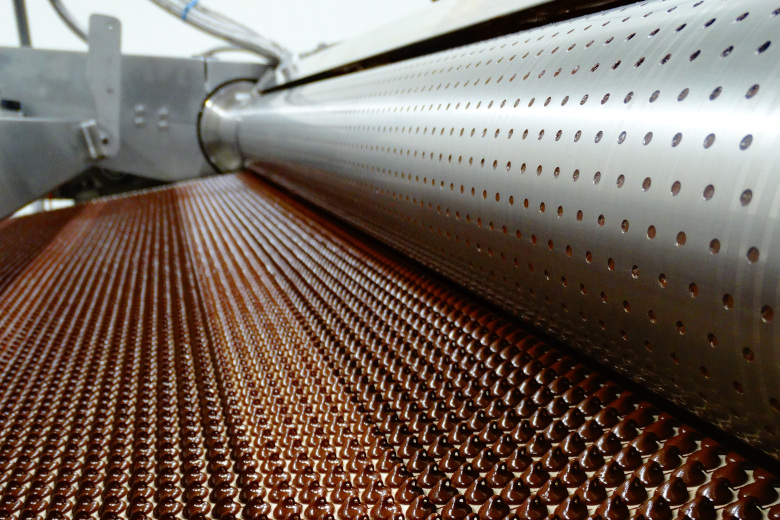

The Rotoform rotary drop depositor is at the heart of all IPCO’s high-capacity solutions. The company will present the latest model in this series – the Rotoform HP (High Performance), specifically designed for chocolate processing. A pump delivers the molten chocolate to the Rotoform via heated piping. The Rotoform itself consists of a heated stator – which is supplied with liquid chocolate – and a perforated rotating shell that turns concentrically around the stator to deposit drops of chocolate onto a continuously running steel belt. A system of baffles and internal nozzles provides uniform pressure across the whole belt width, ensuring that chips are of uniform shape and size.

The circumferential speed of the Rotoform is synchronized with the speed of the belt, to deposit drops without deformation. Chips are free-flowing for easy handling, storage and dosing. Chips of different sizes – from 30,000 to 300 pcs/kg – can be produced.

Triple-pass chocolate cooling systems

IPCO also developed a range of triple pass cooling. The product is deposited on the first belt and adheres to the underside for the second pass. It is then placed on a second conveyor for a third pass. The company recently introduced a piston depositor that combines a “direct-to-belt delivery approach with precision control to enable the production of perfectly circular large – i.e. wide and/or thick – wafer products,” IPCO explains. The piston depositor can be installed alongside existing Rotoform and extrusion equipment on IPCO CCM (Chip and Chunk Moulding) triple-pass steel belt cooler lines. This enables three depositing systems to be integrated on a single line for maximum production flexibility. It can also be installed as an upgrade to older CCM lines, or as a standalone system on new lines.

“One of the most significant additions to our portfolio in the last couple of years has been our piston depositor. This was IPCO’s first solution of this kind and incorporates several state-of-the-art features that take this technology to a new level. The system is a 1,500 mm wide depositor that uses a D-motion to deliver chocolate or compound directly onto a moving belt, rather than the belt-to-depositor movement commonly used on other systems. Software is used to adjust the speed and the height of the depositor and ensure that it travels at exactly the same speed as the belt,” IPCO tells us.

Steel belts

IPCO supplies steel belts for use in confectionery and chocolate, in applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming and casting.

Products processed this way include caramel, chocolate, hard melt candy, nougat, nut brittle and more. In each case, the product is applied to the belt as a melt, either through casting or drop depositing, and solidified as it passes through a cooling tunnel.

The company shared its views on the return of the show and their expectations: “A lot has changed since the last interpack, for our company, too! Six years ago we were still Sandvik Process Systems, so this will be the first appearance of the IPCO brand at interpack. If any visitors are unfamiliar with the IPCO name, it will be an opportunity to reintroduce ourselves and help them make the connection.”

IPCO is optimistic about this year’s Interpack, as the first big food-related fair to be held in Europe since the pandemic, expecting it to attract large numbers of visitors from all over the world.

Photo: IPCO Rotoform. Credit: IPCO