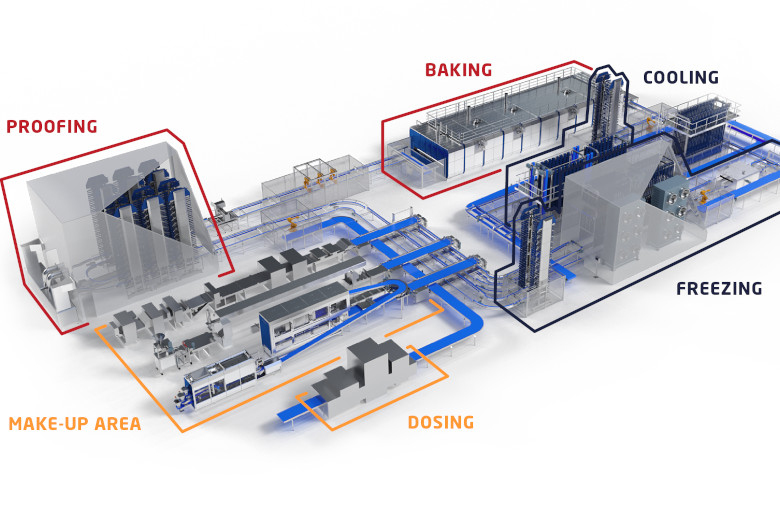

With thriving opportunities for snacks, bakeries innovate to propose new experiences. A technology solution designed for continuous production updates is Mecatherm’s MECAFLEX automated line. Built for product diversity, it is able to run a comprehensive range of snacks, from croissants, buns, and hot dogs, to pains au lait, muffins, ciabattas, Kaiser rolls, or chocolate croissants. In addition, baguettes and larger products such as toast breads, brioches or loaf cakes can also be added into production on this line. “To be relevant and viable, product diversification has to be done without making any compromise on product quality, industrial performance, and sustainability. This wide range of products is made possible thanks to the compatibility of several different make-up lines, using different technologies to process the dough,” explains François Retailleau, Line Product Manager at Mecatherm.

Many processes can be customized, from scoring and seeding to flouring or egg spraying – before baking. There are multiple options to choose from for processes after baking as well, from topping to cutting, decorating, or packaging, for example. Choices have expanded to include solutions from Mecatherm’s sister company, ABI Inc., meaning a whole new range of additional robotic customization solutions is available such as scoring, cake cutting, cake decoration or brand printing.

Another flexibility feature is its compatibility with different types and sizes of trays, pans, or straps. This is possible thanks to the MECAFRAME system – universal grills that can convey any type of bakeware, offering a gateway to industrial production.

One line, two versions

The MECAFLEX line comes in two versions that can each be sized to meet individual production needs. The MECAFLEX Essential make-up is intended for mid-size semi-industrial bakers as a core solution built around the M-TA oven, a piece of flexible equipment by itself, and the modular M-UB proofer. It features the MECAFRAME system, meaning any existing tray, strap or pan can still be used with no changes to the production workflow. Further customization, and cooling and freezing steps remain manual with this version.

Mecaflex Advanced is the complete and fully automatic solution, which covers automated customization, cooling, and freezing steps, as well as an automatic tray changeover. The Advanced version uses dedicated trays to help increase the efficiency of a fully-automated process: in this way, complex handling operations that would be necessary to load and unload existing small trays from a MECAFRAME system are reduced to a minimum. “This solution is intended to mature industrial bakers, but is also available as an upgrade of Mecaflex Essential, which was designed to allow upgrades and the integration of additional modules,” the specialist explains.

The MECAFLEX aims to meet both current and future product diversity and can optimally plan their parameters and order.

Read the full article in Baking + Biscuit International, Issue 1, 2022!