In a time when change is the only constant, bakeries need to generate new ideas at an increasing pace and solve challenges in a human-centered manner. One of these challenges is the successful implementation of automation in the production process of baked goods.

The chapter “Design Thinking” (Automation, Science and Technology, 2021 – a book published by Food2Multimedia GmbH) describes how design thinking could improve this change process in industrial-scale manufacturing environments.

In a volatile, uncertain, complex, and ambiguous (VUCA) environment, companies have to continuously adjust their existing processes to changing conditions. Structural and technological changes in the baking industry have been (e.g. Storey & Farris, 1964) and still are subject to scholarly attention (e.g. Hecker et al., 2013). One significant innovation in this regard is the automation of processes. However, there is no one-size-fits-all solution for how automation can be introduced within every bakery. Each implementation rather requires several adjustments to leverage the optimization potential. Furthermore, successful change in a complex, rapidly transforming environment requires a motivated workforce with sufficient leeway for responding to changes in a self-determined manner.

A team-based method

Due to the VUCA environment, prefabricated blueprints for managing change are of limited use. For instance, due to changing customer preferences, such as more emphasis on healthy and sustainable goods, labeling food products becomes more important. However, introducing new labels might require a new quality management system. Thus, bakeries need agile approaches that iteratively integrate new insights into the solution process along the way. One of these new approaches is design thinking, a team-based method that relies on a defined process and takes human needs into account before developing a solution (Endrejat & Kauffeld, 2017; Norman, 2013). Initially created for product and service development (due to its participatory and iterative style), design thinking is also an agile approach to implement organizational change (e.g. Elsbach & Stigliani, 2018; Endrejat et al., 2018).

In this chapter, I describe the design thinking mindset and process based on the challenge of “using automation to increase speed and efficiency of the communication and ordering between bakeries and subsidiaries”. Furthermore, I provide general recommendations for introducing this innovative approach into organizational routines.

Problems often arise from poor design. In this context, design goes beyond aesthetic aspects but refers to how users interact with objects or processes. This is because trying to fundamentally understand the problem and frame it into a solvable solution often runs opposite to the predominant organizational culture (‘we have always done it this way’). To overcome the forces of perseverance, more and more organizations are recognizing that a user-centered approach is necessary to design change that promotes desired behavior. Thus, one goal of design thinking for organization development is to systematize the approach of designers and turn it into a process that can be practiced in organizations.

Design thinking rests on an iterative process by which a team continuously gathers new information about a given challenge and integrates the perspectives of relevant stakeholders into the solution process. This is particularly relevant for organizational transformation – like the implementation of automation – because it invites the workforce to co-design a change, using its expertise, and creating commitment to the solution.

The design thinking mindset

Design thinking rests on the optimistic, empathic, and action-oriented conviction that a solution is out there and that by keeping focused on human needs – and asking the right questions – the team will get there.

Instead of presenting final solutions, design thinking involves employees in a process that helps them to understand the causes or the meaning of a necessary change. In this way, those affected are given the opportunity to contribute their views and wishes. In the common terminology of organizational science, it is a bottom-up approach: The data of the employees are collected, put together and developed into a new solution, which is then carried upwards in the organization. This approach contrasts with the traditional top-down approach in which the management specifies how existing processes are to be improved incrementally and then expects the workforce to adopt these changes.

Design thinking does not ignore problems and challenges, but also does not demonize ‘resistance’ by change recipients and rather understands it as an expression of needs that have to be acknowledged.

This reinterpretation allows us to work together on solutions – true to the motto ‘energy flows where attention goes’. The decisive criterion is which solutions are sufficient to meet the requirements of the users. Instead of evaluating solutions according to right and wrong, it is about examining which concepts meet the stakeholder needs.

The design thinking process

A design thinking process usually begins with a challenge defined by the management or other relevant stakeholders that see room for improvement or the need for change in a certain area. Such a challenge might be: “using automation to increase speed and efficiency of the communication and ordering between bakeries and subsidiaries”.

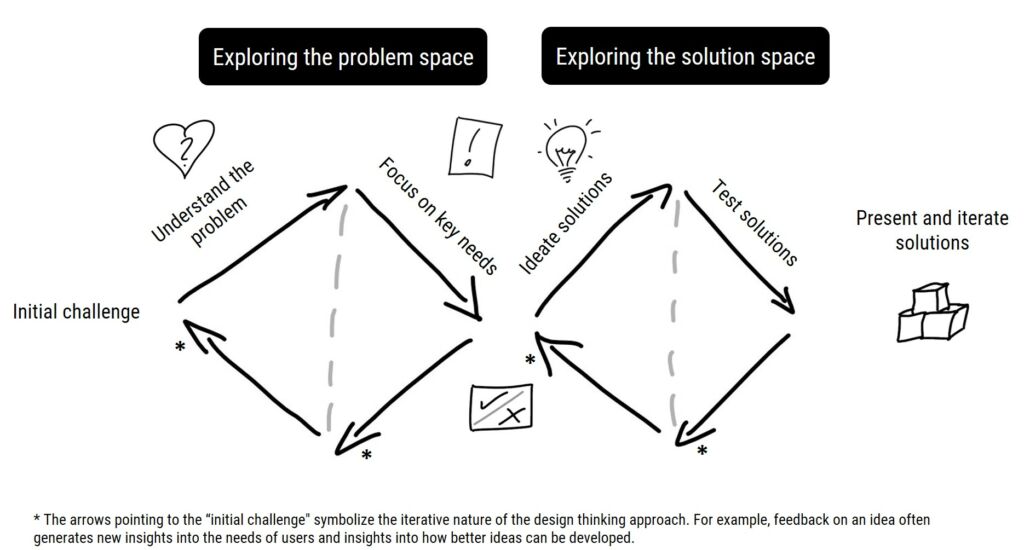

A design thinking project consists of several phases that are necessary for a successful innovation process, from the initial challenge to the successful implementation, placing a strong focus on a detailed needs analysis. An established process model is the ‘double diamond’ developed by the Design Council (2007) that includes two phases of divergent and convergent thinking, respectively.

Divergent means that new directions of thinking are explored in order to gain as much data as possible about the concerns of the employees. During convergent thinking, this data is structured and, if necessary, reduced to define clear needs and solution ideas. Both ways of thinking can be found in the needs analysis as well as in the solution phase (thus the name ‘double diamond’). In the first step (discover), the design thinking team gathers as much information as possible about the perspectives of their colleagues (divergent thinking) and then focuses on a few central concerns that they would like to solve (define). In the subsequent solution phase, various options and possibilities are thought through to take the needs of the employees into account (develop), and select and develop a promising proposal (deliver). Each of these steps is described in the following sections.

Discover (divergent thinking)

In the first process phase, the design thinking team tries to gain a deep understanding of users’ perspectives, preferably on vivid insights that are gained through observation, interviews with colleagues as well as subject matter experts.

Define (convergent thinking)

After collecting a lot of information during the discovery phase, design thinking teams have to focus on the relevant insights. Key needs of employees could be phrased into “How to…” questions. After structuring the employees’ needs, the transition from the needs analysis to the solution phase takes place. Often, this goes along with re-framing the challenge or focusing on the most relevant aspects.

Usually, the users’ key needs are translated into “How might we …?” (HMW) questions. A HMW question consists of only three words but these are carefully chosen to guide the team into a creative trajectory. How. Implies that solutions exist and that there is a possibility the team can find them. Might. Suggests that hypothetical solutions are being developed and gives permission to explore unorthodox avenues (underlined by the subjunctive). We. Assigns responsibility to each team member and facilitates collaboration necessary to generate results.

By selecting and merging the most relevant “How to…” questions (convergent thinking), the design thinking team creates a tangible HMW question. In our example, the question could be “How might we combine algorithms and the expertise of local employees to increase the efficiency of ordering processes?”

After the team has defined the key challenges, it moves from the problem definition to the solution phase (i.e. the second diamond).

Develop (divergent thinking)

To generate creative user-centered solutions for the defined HMW question, the team is encouraged to think out of the box (what wows?) because employees seldom think up but rather tend to tame down. For this purpose, design thinking teams use various creative techniques such as brainstorming or -writing, the six-thinking hats (a method of approaching the challenge from different perspectives (=wearing different hats), developed by Edward de Bono in 1999), or mash-ups (a method that creates new insights by forming associations between unrelated domains).

Deliver (convergent thinking)

In this phase, the design thinking team has to select and focus on ideas it considers promising to proceed. During this step, the ‘wow’ ideas are rendered into ideas that work and could be integrated into organizational structures. A key aspect of design thinking lies in prototyping in order to quickly generate solutions. The goal of prototyping is to collect feedback from users if the solution path goes towards a desired direction. Prototypes not only test an idea but also generate more knowledge about the needs of the employees.

For the challenge of combining algorithms for the bakeries ordering processes and the expertise of local employees, the team might decide to progress the idea of “providing training so that the ordering algorithms can be written by the staff of the subsidiaries”. While prototyping the agendas for such types of training, the team might receive feedback that the content of the training would be too detailed and complicated. Instead, the employees might wish to gather a basic understanding of the working modes of algorithms. So the IT department could produce a short video that explains the algorithm modes.

Furthermore, the design thinking team might learn that this rendered idea fits well with the office hour idea (employees provide feedback to the algorithm engineers) but it would suffice that these take place quarterly.

At a glance

Automation is an innovation that has the potential to disrupt the baking industry. To help bakeries cope with challenges proactively, this chapter described the design thinking approach. The design thinking process and mindset help to manage the transformation in an agile and human-centered manner. Furthermore, I offered three recommendations (ensure that (1) the team consists of motivated members, (2) has a bias towards action, and (3) has leeway to generate solutions) to increase the success of design thinking as a tool for organization development.

If these recommendations are taken into account, design thinking contributes to an improved problem-solving capability of organizations (Carlgren et al., 2016). Besides ‘superficial’ gains of the design thinking approach (e.g. better process design), the integration of design thinking into organizational structures also leads to employees developing a holistic understanding of the organization, and creates a climate in which different opinions and arguments can be discussed constructively. Not only does that bring a competitive advantage, but it also helps to make employees’ work environments more meaningful (Buchanan, 2015). Nevertheless, such an approach also requires a change in employees’ thinking: Instead of managers generating solutions for employees, those affected themselves develop concepts on how their needs can be taken into account in the future. In this way, design thinking helps employees become ‘authors’ of their organization as opposed to being simply ‘readers’.

Author

Dr. Paul C. Endrejat is co-founder of The Why Guys GmbH (www.thewhyguys.de). The Why Guys help organizations adapt to external challenges and create an environment in which employees can grow and work in a self-determined manner.

Contact: [email protected]

The full article was published in the Automation, Science and Technology book, published by Food2Multimedia: ISBN 978-3-9824079-0-6, 1st edition, 2021 (Hardcover edition, 180 pages); ISBN 978-3-9824079-1-3 (PDF). Printed by Leinebergland Druck GmbH & Co. KG.