Innovation in Artificial Intelligence algorithms can be applied to baking processes for improved results. AI’s ability to learn and auto-learn makes it particularly resourceful to increase process efficiency and seamlessly handle a great variety of products by identifying the sets of features to be controlled.

Quality control is one of the areas in which Artificial Intelligence can make a difference in bakeries. It can contribute to greatly improving product quality and productivity: such smart vision inspection systems are flexible enough to be able to adapt to changes that occur during production. Moreover, the algorithm ensures that every single product is inspected, with no exceptions. It has the ability to do this for production speeds of up to 12,000 products per minute, then generate data and reports. To achieve this, multiple measurements are made simultaneously, while the line is operating at full speed. Non-compliant products are at the same time removed.

SENSURE designs AI-powered vision systems for industrial quality control, particularly focusing on bakery products – to identify and remove non-compliant products and to manage their flow as they exit the oven and reach the packaging machinery. Its SENSURE Synapse Bakery Solution does just that.

Synapse with AI

AI makes up the core of the system, for the Synapse Bakery and all other SENSURE solutions, and enables it to perform various functions such as the automatic selection of the characteristics to be controlled in the products, and the optimization of the tolerances of the controlled measurements.

AI also automatically creates simple pre-configurations of the system, which is “a very useful and effective starting point,” Daniele Vaglietti, Sales and Marketing at SENSURE tells us. “Thanks to these innovative AI algorithms, it is the system itself that identifies the characteristics to be controlled, by automatically adapting to different types of production and its intrinsic variability,” he explains.

Synapse Bakery can be used to continuously improve production. It provides the tools to understand where and when production is stable, according to specifications, and it can also tell what/when a problem occurs. It can also be integrated with third-party systems such as ovens, packaging machines, metal detectors, checkweighers, moisture analyzers, and other types of equipment, resulting in fully integrated production lines. It can exchange input/output data with many communication systems, management solutions, company networks and line PLCs. “This feature makes the system perfect for accepting configurations and settings from the line, generating data for feedback systems and for constantly monitoring what is happening in production. For these reasons, Synapse Bakery is a perfect match for the requirements of Industry 4.0.,” he highlights.

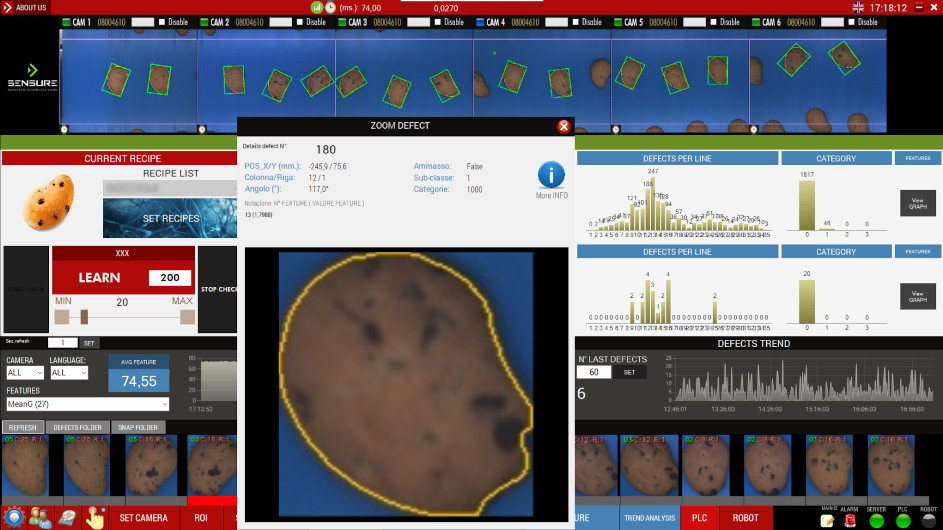

The system is designed to manage different types of rejection methods, single or multiple, with various technologies (e.g., air nozzles, traps, retractable conveyors, robots, etc.), through connections with PLCs and ROBOTs of different brands. Several aspects determine the correct choice, such as the products, the type of line, or the processing speed. SENSURE developed an intuitive, dedicated graphic interface between the artificial system and the operator, to streamline operations. This solution also provides a complete defect analysis; all defect data and images are stored in a dedicated folder and the system is also able to provide an analysis of the defects, explaining the logic behind the rejection process. Using this graphic interface, the software performs the adequate quality control operations for different product types by integrating 2D and 3D vision technologies.

Never stop learning

The ‘Learn’ function is key for the SENSURE system. The Synapse Bakery system can automatically learn the relevant features of the production. “Just a simple button in our interface (‘Learn’) and our AI algorithms can recalibrate the system to the current production needs, drastically reducing the time requested for start-up and all following modifications,” Vaglietti highlights.

The ‘Learn’ function also supports production during issues that typically occur on the line, such as oscillations in oven parameters (while still in the correct quality range), or product variations due to differences in raw materials, for example. The ‘Learn’ feature also provides support when a new recipe is created by an operator without a background in vision systems. Among its unique functions that help optimize production is its ability to ‘re-center’ the quality criteria during a momentary critical production phase, to minimize waste and better manage production needs, in another example.

The system, thanks to the ‘Learn’ feature, proposes a quality recipe and tolerance thresholds, allowing the operators to make subsequent modifications. To work with this function, operators can choose the time when the system has to adapt to certain product specifications. They can also control how many products will be used during the learning phase. Usually, it takes less than a minute of production to get the system up and running. This operation can be done at any moment of the production.

There is ‘Learn’, and then there is ‘Auto-learn’. The ‘Autolearn’ function is an option that allows the system to learn continuously. By doing so, the system ensures that no drift can occur: “It’s the system itself that chooses the best time to adapt to production changes. ‘Learn’ and ‘Auto-learn’ are innovative functions that allow the system to remain very aligned and adherent to production changes, reducing waste over time,” the specialist explains.

Handling product variability

The Synapse Bakery is designed around product variability – a regular occurrence in production. The system identifies variations, drifts and quality problems normally present in a production environment. It then performs all related actions automatically. The Synapse system is already incorporated into and working on diverse bakery lines. It oversees the production of a comprehensive range of bakery goods, such as biscuits, rusks, snacks, crackers, cakes, breads, pizza, donuts and more. It also handles decorations with different shapes, colors, and pattern details. “We have developed more than 50 quality control features for shape, size, color, surface patterns and other parameters – and we can always develop new ones if needed,” Vaglietti says.

The engineers at SENSURE are working to add new functions, sensors, features, and reports. Input coming from customers is also taken into consideration in this process. Variability is also considered for different types of bakeware the products might require; the system can work with products placed in various trays or tins, and will similarly follow the product once it has been removed from its support and placed on conveyor belts or other types of transportation means. “The system has very flexible configurable software that allows it to work with products on trays with single or multiple items on them,” he explains. In addition, the Synapse system can be placed before and after the oven, to control the complete production cycle.

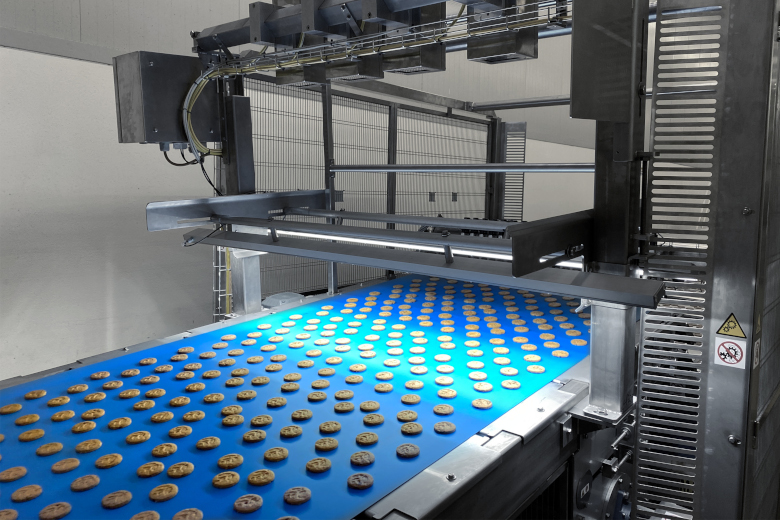

Bringing the AI home

Installing a Synapse Bakery system that only takes images and measurements from above, either 2D or 3D is fairly simple: “The system is typically mounted on a framework transversal to the line, and it is controlled by an electrical cabinet that can be located up to 100 meters away from the line. Complete solutions for quality control can inspect the product’s top and bottom sides, in 2D and/or 3D. Once up and running, the maintenance the system requires is minimal; it all amounts to cleaning lights and camera protections when needed.” The system has no consumable parts.

Italian bakery “Il Vecchio Forno” recently installed a vision system for pick-and-place operations and for the quality control of its rusks. The company produces rusks and naturally leavened baked desserts such as panettoni, pandoro and colombe. The SENSURE Synapse vision system was installed on the bakery’s new production line for rusks to control the entire manufacturing process. It automatically identifies and rejects non-compliant products and optimizes the flow of products at the entrance to the packaging machines. Four vision systems (each one with seven high-resolution cameras) were installed on this line to identify defects in the shape, color and size of all rusks as they come out of the oven.

There are 40 ABB FlexPickers that receive the coordinates of the compliant products from the Synapse software and deposit them on belts feeding eight packaging machines. The non-compliant products arrive at a final conveyor belt to be rejected.

The SENSURE SYNAPSE software provides real-time visualization and dedicated reporting, which can be used for process optimization, production control and predictive maintenance.

Read the full article in Baking+Biscuit International, issue 3 – 2022.