Many things can be mapped digitally. But not everything! Nothing quite beats the real thing and exchanges between people. After its online trade fair in the summer, the bakery systems manufacturer MIWE therefore decided to organize a “Live Expo” at its headquarters.

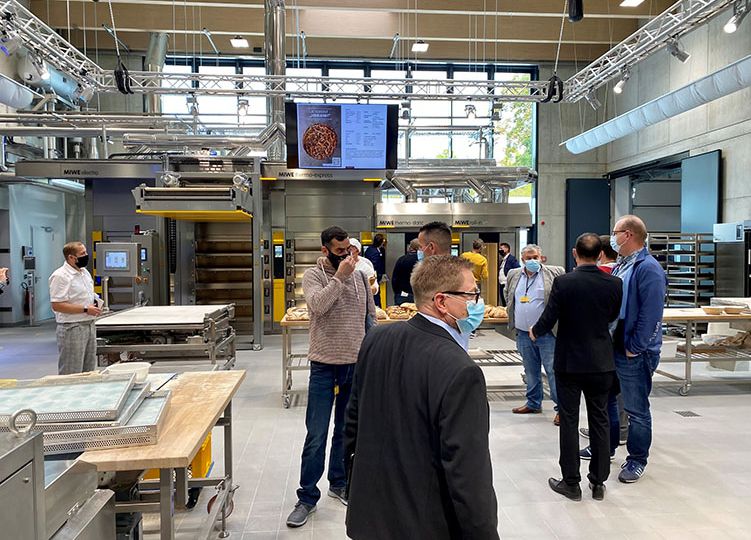

‘Experience baking technology live’ – this once would have been taken for granted but sounds strange in the extraordinary times we are now experiencing. Demand was there. And the in-house exhibition – it was also the first for MIWE – was well received. With a limited number of participants and under strict hygiene conditions, the event took place on four dates in the MIWE live baking center (LBC), the company’s demonstration bakery at its headquarters in Arnstein/Germany.

In the 1,600 m2 LBC, MIWE demonstrated the entire production processes of various baked goods. In order to cover all areas from dough making and processing to bakery

refrigeration and in-store baking, the expertise of partner companies was introduced, including Diosna, Rheon and IREKS.

How do the baking properties of the MIWE heating gas circulator positively affect the baking results when compared to those of the MIWE thermo-express thermal oil-heated deck oven, for example? Amongst other things, the visitors could make a direct comparison using the example of rye mixed bread, which was baked in both ovens at the same time.

Those who wanted to could switch from the live demonstrations to the accompanying lectures. Karl Heinz Hustings, Head of the Bakery at LBC, delivered a report on the long time dough method, which was greeted with great interest. In this he explained and demonstrated, giving concrete examples, on how night work can be shifted to day with the quality of the baked goods being enhanced at the same time. A factory tour of the oven production in Arnstein rounded off the in-house exhibition. As well as Arnstein, MIWE has a second production site in Germany.

AI at the preparation place

When it comes to the topic of “digitization in store management”, the company is currently working on an intelligent solution for the preparation area. It is an “assistance system with AI” which instructs employees step by step to place the right product on the baking trays and to position the products correctly. If the employee does something incorrectly, the system indicates the error in real time with unmistakable images and symbols on a screen. This system is intended to make work easier, especially for unskilled workers. The assistance system with artificial intelligence (AI) is a logical extension of the MIWE shop baking suite (sbs). This management software is used to administer all systems and processes in the store environment.

The MIWE live baking center (LBC)

The MIWE live baking center (LBC) is the figurehead of the company. Here you can find almost everything that MIWE Michael Wenz GmbH has to offer in baking technology* (see below). In addition to the bakery itself, it also includes an analysis room and six seminar and meeting rooms. All are equipped with the latest media technology and digitally networked. “Bring your own device” is possible and there are large monitors, up to 98″, some with touch screen, which facilitate visualization and discussion when it comes to new product developments, process comparisons or bakery planning.

Since its opening – the LBC was launched at iba 2018 – it has hosted visitors from over 60 countries, including Italy, Sweden and the USA as well as Israel, China, Hong Kong, Egypt and the Commonwealth of Independent States (CIS).

What can bakers use the LBC for?

+ Test runs: What product character can be achieved particularly well with thermal oil? What are the consequences for recipes and processing? What are the processes when using vacuum conditioning? Bakers can clarify these and other questions by carrying out test runs on-site and can also bring their own raw materials.

+ Product and process development: It’s not usual for anyone working on a new product or new process to go into series production immediately. It’s normal to optimize it using small batches. In the LBC, alternatives can be tested.

+ Workshops and further education: MIWE conducts advanced training and workshops periodically. According to the company, the “MIWE roll-in intensive seminar”, which focuses on the numerous possibilities for fine adjustment of the rack oven – including ‘atmospheric baking’ – is particularly popular.

The equipment:

In the field of bakery refrigeration technology:

+ Fully automated proofing unit MIWE GVA e+ (as well as the small version in cabinet form MIWE GVA-S)

+ Flash freezer MIWE SF-V

+ Sucking flash freezer MIWE SF-D

+ MIWE TLK dough preservation system

+ Climate chamber MIWE KR

+ Vacuum conditioning MIWE VC

All are operated with CO2 as refrigerant.

In the energy sector:

+ Energy recovery system MIWE eco:nova

+ MIWE eco:control energy monitoring system

+ Buffer storage

In the area of production ovens:

+ MIWE ideal deck oven (heating gas circulator, heated with oil or gas)

+ Electrically heated deck oven MIWE electro

+ Thermal oil heated deck oven MIWE thermo-express (including central heating boiler in the technical room)

All three are connected to the MIWE sherpa loading system.

+ Thermal oil heated MIWE thermo-static wagon oven (with central heating boiler in the technical room)

+ Rack ovens: MIWE roll-in and MIWE orbit

In the area of in-store baking:

+ MIWE condo deck oven (in various designs, also with integrated loader)

+ Wenz 1919 deck oven (MIWE condo with cast-iron oven door)

+ Convection ovens MIWE aero and MIWE econo

+ Combi system MIWE backcombi (combination of convection and deck oven)

+ Modular FreshFoodSystem MIWE cube

+ Convection ovens with gastronomic applications: MIWE gusto and MIWE gusto:snack

+ Convection oven with loading trolley for food retailing: MIWE FBC

In the field of digital solutions:

+ MIWE shop baking suite

+ All systems are networked