Trays come in shapes and sizes as diverse as the products that they will help to make, while also considering the equipment and handling methods in each bakery. A characteristic they all have in common, regardless of endless possibilities in their layouts, is the safety guarantee provided for the products baked, time and again.

Tray cleaning down to a science

Cleaning can quite literally make or break the trays, respectively their life expectancy. This, in turn, comes with a double cost: first in replacing/recoating the pans and, just as importantly, in production time lost. Specializing in cleaning machines for baking trays, Austrian company Precisma develops equipment configured for specific requirements. As for possible customizations to the cleaning equipment, “No client specification is beyond us,” believes the General Manager, Alois Aichinger.

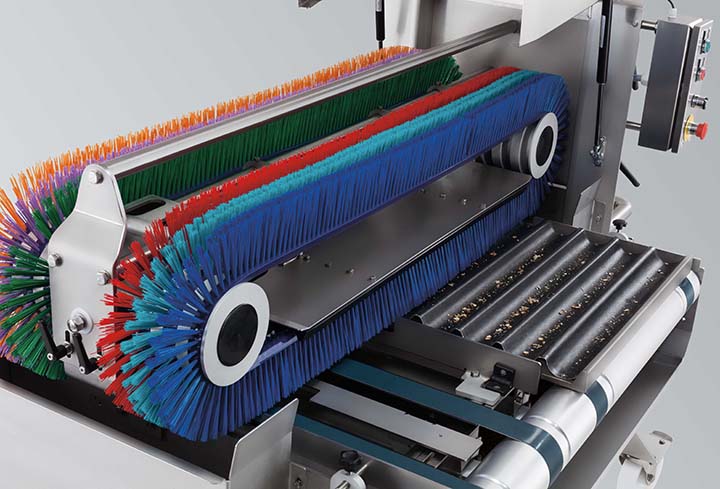

Precisma’s tray automatic cleaning system for baking lines, ‘BELT Industry’, is designed with easy integration with various technologies in mind. In addition, it can be customized to match the bakery’s needs. It can be configured for any cleaning task thanks to a multitude of options, e.g. washable design, for continuous operation, Precisma details. This machine has a cleaning performance of around 1,200 sheets per hour and removes any leftover flour, seeds and rough efficiently. Its brushes work in opposite directions to one another to adapt to the bakeware contours and reach all parts of the molds and tray channels.

The ‘BELT Standard’ cleaning machine is designed to clean baking trays with up to four rims in large quantities, as well as baguette and burger trays. The basic version can be fed manually – in which case it is made up of a cleaning and a conveyor unit. It helps save energy compared to wet cleaning and is also particularly suited for bakery production lines, in the form of individually adapted automated systems.

The ‘Easy Belt’ is the newest entry in the company’s portfolio. This recently-developed tabletop baking tray cleaning machine is meant for universal use by small businesses. For this purpose, its design prioritizes flexibility in terms of types of trays it can thoroughly clean, over quantities. It incorporates the company’s Belt cleaning technology and its use is as simple as setting the machine down on a table and sliding the baking trays through it manually, Precisma recommends.

No matter what types of products are in current (and future) manufacturing rotations, choosing the right bakeware for the job, handling and cleaning it as intended can help achieve significant savings and guarantee product safety, with every bake.

The article is part of an extended feature, which was originally published in [BBI 5 – 2021]. Read the full article in the magazine: