Automating labor-intensive, repetitive work in bakeries by use of robotics helps perform complex movements and round-the-clock tasks.

Besides the packaging area, where robotics are well established, production lines can similarly automate processes including storage, scoring, depanning and dough resting systems. Kaak develops robotic applications specialized in performing different types of tasks along the bakery line. The company started building 3D vision guided scoring systems using robotics and expanded the use of robots on the bread processing line for all kinds of handling automation. Fueling this development are the recent shortage and rising costs of personnel.

Scoring with robots

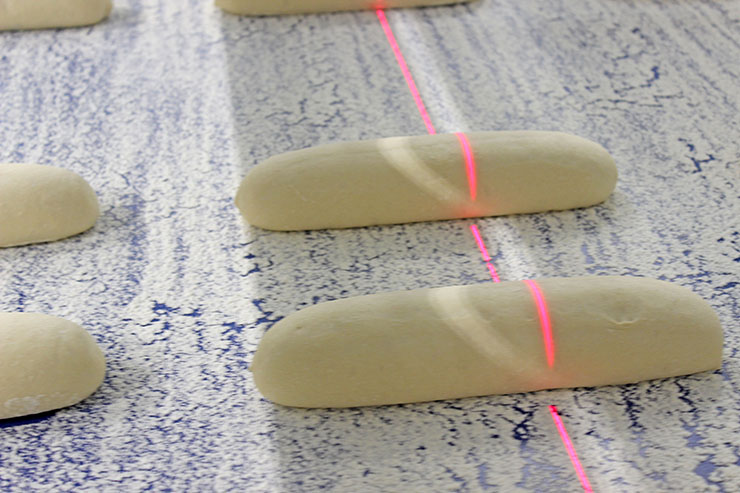

Dough scoring has been vastly automated in industrial bakeries, observes Kaak; the company has installed around 200 robots. Conventional, xy-scoring systems were mainly used for products that are perfectly aligned on defined positions in carriers and scored in fixed patterns by a series of knives. This solution works well for mono-product lines. However, demands for a large variety of different luxury products with complex scoring patterns is growing, since it is a powerful way to reflect the brand identity and make products truly unique. This is where robots come into play. “Scoring is a very complex movement that was only done by humans. This is the clear advantage of the robot,” Michiel Dix, underlined. Traditionally, the baker ‘scans’ the product to determine how deep and where to score. The recognition of different products, their curve and height, as well as the cutting movement itself, is now also done by the Kaak robotic scoring systems. 3D-vision technology is instrumental to this. It recognizes the product’s position, orientation and shape and sends this information to an industrial computer, where the logistics of assigning the robots tasks are handled. From the computer, the robot receives the information related to the product command about the movement it should perform, Teun Verkerk detailed. “A robot is by definition suitable to make such complex movements, guided by 3D-vision to follow the contour of the dough piece.”

Scoring is a process that requires skill and shows the baker’s experience when done manually. Alternatively, as labor is becoming harder to find (and then keep), robots can efficiently take over the task; they will never need to stop and will perform constantly over time. As the trend for artisan-style products is growing, the concern might be raised whether the resulted products would all be identical, ‘robotic’. Of course the scoring will be uniform and perfect for each individual product, despite differences in shape and position of the dough pieces. Dough is a living substance. If scoring is constant, when the bread is being baked, there still will always be small differences between each product, maintaining the artisanal look and feel.

Kaak has installed many 3D controlled cutting systems over the last six years, operating in various combinations anywhere from 1 to 12 robots, depending on the requirements. There are different kinds of scoring tools available that best suit the product properties of each bakery. For example: the scalpel knife, the rotating knife, and the water jet. They have quick-release systems, so the operator can swap them by simply using a handle or it can be done automatically.

The recipe programming is designed to be intuitive and user friendly. Input of the scoring parameters is made easy as the input data is visually represented on the screen for quick recognition of the scoring pattern. The HMI also provides operational information of the performance of the scoring application.

Key points driving the use of robotics in bakery

+ Robotics provides simple solutions compared to more complex alternatives

+ Covid has fueled discussions on automation and robotization. Limited availability of personnel and rising personel cost have triggered many bakeries to further automate their production processes using robots

+ Robots simplify production planning due to the absence of variations in availability of personnel.

+ Fast return of investment, e.g. as fast as 2-3 years for Kaak’s scoring aplications

Robotic handling

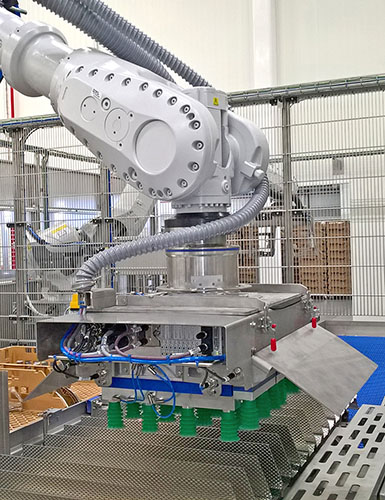

There is also a growing demand for robotics for storage, Kaak observes. In bakery processing lines, the Dutch company sees a vast array of applications in which robots can be of added value over traditional equipment. These robots can perform complex movements in a very flexible and efficient way, resulting in higher output and efficiency of the production line. In addition in applications where tedious, repetitive and difficult tasks are performed by humans, robots can perform these tasks cheaper and more cost-effectively. Examples of these applications include depanners, carrier storage, dough resting systems and many more.

Carrier storage applications

As an example, Kaak sees a growing demand for robotic storage automation, handling baking trays, straps and lids. “Besides the fully automated gantry systems that Kaak has been building for many years, we see a growing demand for more flexible and smaller sized robotic storage applications.” Automated storage systems using robots are a simple and cost-effective solution for mid-sized production lines, where flexibility is key. This means robots that can correctly identify, pick, and place carriers, keeping them and their coatings safe from any damage while handling them. All solutions are custom-built, according to production requirements and the floorspace available, to seamlessly integrate their work on the line.

Future-ready

Kaak keeps investing in further developing robotic applications in the following years in those areas where tedious, repetitive and difficult tasks are better off assigned to robots. The goal is the complete integration in the total line control, to increase process efficiency.