On-the-go or in home offices, nothing seems to be able to slow snacking down. Snacks are also increasingly the preferred option over regular mealtimes. Together with the hunger to snack, however, the demand for more diverse, healthier and tastier products also grows. Flexible technology is needed for the task.

The demand for healthier products is growing throughout all product categories in the food industry. One iteration brings clean labels to the forefront, which encompasses the general expectation for healthier and more natural products. Three-quarters of all food manufacturers are currently reformulating their products to be aligned with these new trends, according to Mecatherm. Opportunity is thriving for snacks, as bakeries innovate to propose new experiences, special and personalized products to meet consumers’ preferences. This is illustrated by a spectacular increase in new product development in bakery, up by 60% in the last 10 years (Mintel).

A technology solution designed for continuous production updates is Mecatherm’s MECAFLEX automated line. Built for product diversity, it is able to run a comprehensive range of snacks, from croissants, buns, and hot dogs, to pains au lait, muffins, ciabattas, Kaiser rolls, or chocolate croissants. In addition, baguettes and larger products such as toast breads, brioches or loaf cakes can also be added into production on this line. “To be relevant and viable, product diversification has to be done without making any compromise on product quality, industrial performance, and sustainability. This wide range of products is made possible thanks to the compatibility of several different make-up lines, using different technologies to process the dough,” explains François Retailleau, Line Product Manager at Mecatherm. For products with different shapes and doughs, different make-up technologies can be placed in parallel, to cover molding, sheeting, rounding, or just batter dosing, as needed. “For this entire solution, the layout has been thought of so that the line remains compact and footprint efficient. For a fully-automated MECAFLEX Advanced, the floor space required is less than 2,000sqm,” he illustrates.

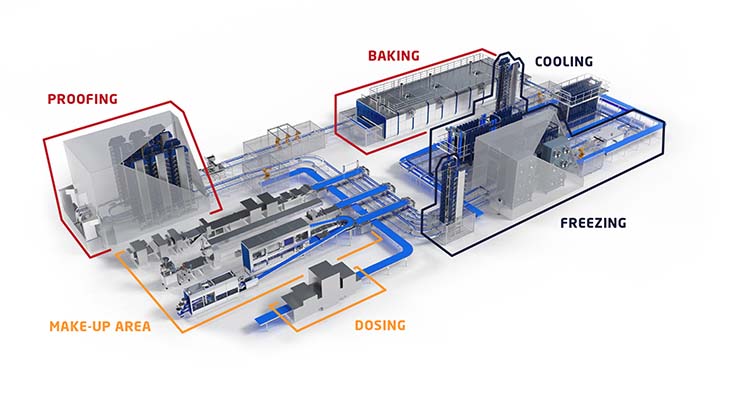

Downstream, the line follows the main process steps shared by the majority of bakery and pastry products, i.e. proofing, customization, baking, depanning and, optionally, cooling and freezing. The technology specialists included generous space for customization areas before and after the oven, allowing for either manual or robotic operations. Many processes can be customized, from scoring and seeding to flouring or egg spraying – before baking. There are multiple options to choose from for processes after baking as well, from topping to cutting, decorating, or packaging, for example. Choices have expanded to include solutions from Mecatherm’s sister company, ABI Inc., meaning a whole new range of additional robotic customization solutions is available such as scoring, cake cutting, cake decoration or brand printing.

Another flexibility feature, confirming the name of this line, is its compatibility with different types and sizes of trays, pans, or straps. This is possible thanks to the MECAFRAME system – universal grills that can convey any type of bakeware, offering a gateway to industrial production. “With MECAFRAME, we give the possibility to industrial bakers of using any existing tray, strap or pan at an industrial scale. It is particularly adapted to mid-size bakers, who already have an existing wide range of products and therefore trays, typically small that can easily be handled manually,” details Retailleau.

The (fastest) way around all products and production volumes

Adding to the product ranges, the MECAFLEX line can also adapt to high variations in production volumes. The same baking system can produce anywhere from 750 brioches per hour up to 18,000 buns per hour, for example. However, there are guidelines that should be followed to maintain efficiency: one of the key priorities in this regard is to manage very precisely both the batch sizes and the changeover times between them.

This is where Mecatherm’s simulation software, the M-PLAN, comes in to help establish the optimal production sequence. It is designed for a double role, to help production managers to accurately size production gaps and to properly sequence product batches. Sizing production gaps accurately will help eliminate missed changeovers, avoiding potential line downtime and, potentially, significant emergency manual handling. Alternatively, finding the best sequence for the production is key. “We often use an example showing the sequence of three products manufactured on one line. The difference between the best (brioche – buns – focaccia) and the worst (buns – focaccia – brioche) sequence makes up for 6% of additional line availability over one day of production, with the exact same quantities produced on the line,” Retailleau explains. The time savings can even go as high as 10%, by chaining the production batches in optimal order.

Choose your own automation level

The MECAFLEX line comes in two versions that can each be sized to meet individual production needs.

The MECAFLEX Essential make-up is intended for mid-size semi-industrial bakers as a core solution built around the M-TA oven, a piece of flexible equipment by itself, and the modular M-UB proofer. It features the MECAFRAME system, meaning any existing tray, strap or pan can still be used with no changes to the production workflow. Further customization, and cooling and freezing steps remain manual with this version.

The M-UB handling system is made to support easy changeovers between products. The MECAFLEX proofer does that with its six M-UB modules, which can each be bypassed, dividing the proofing process and timings as needed. This proofer is also equipped with two independent thermal zones, each one managed by a separate air handling unit. “This makes the thermal transitions more efficient,” Retailleau details, “as it is no longer necessary to empty the whole proofer to switch from 35°C to 22°C, but only half of it. “It is also very interesting to be able to adjust very precisely the proofing temperature to exactly what the product requires,” he points out. The M-UB system also ensures gentle product handling. It uses a pusher-free transfer system to do so.

Mecaflex Advanced is the complete and fully automatic solution, which covers automated customization, cooling, and freezing steps, as well as an automatic tray changeover. The Advanced version uses dedicated trays to help increase the efficiency of a fully-automated process: in this way, complex handling operations that would be necessary to load and unload existing small trays from a MECAFRAME system are reduced to a minimum. “This solution is intended to mature industrial bakers, but is also available as an upgrade of Mecaflex Essential, which was designed to allow upgrades and the integration of additional modules,” the specialist explains. The switch from MECAFLEX Essential to MECAFLEX Advanced can be easily made thanks to ‘bridges’ available between these two options.

Mindful efficiency

This versatile line accommodates the processing needs of a wide range of baked snacks and staple products by taking agility to the drawing board to cover an extensive checklist: it is aimed at shortening the time to market, to provide versatility for any semi-/industrial setups, process efficiency and agile monitoring. Production parameters can be set each step of the way, from make-up to packaging, the optimum baking supports can be employed and any needed circuit can be adapted. New products can be tested and developed on this line directly, and they are ready to market as soon as the R&D is completed.

In addition, “The MECAFLEX supports the ramp-up of production volumes thanks to a good capacity potential. When a product becomes a best seller and volumes are getting high enough, it then makes sense to invest in a dedicated production line and keep using MECAFLEX for other products with lower production volumes,” Retailleau details.

Sustainability was also an important aspect of the design of this line. Resource efficiency starts, naturally, with the oven, which is why Mecatherm equipped the MECAFLEX with its latest-generation technology, incorporated in the M-TA oven. Not only it is the flexible oven choice for a line that should excel at baking vastly different products, but it is also available in a more sustainable version – with fully electrical heating. And, even with conventional heating, the convection-based technology integrated into the M-TA oven can circulate air at lower temperatures, meaning less energy waste. There is also an option to assist users in setting up the chimney valve opening to an optimum level. The target is again to prevent any energy waste by limiting the flow of rejects to the minimum required.

The MECAFLEX aims to meet both current and future product diversity and can optimally plan their parameters and order.