Formulating and perfecting the recipe is only the start to having great-tasting, crunchy or soft bakery products. The freezing process is essential to how their properties will be captured and preserved.

Freezing baked products or dough requires special care, to ensure their structure is not damaged in the process and shelf-life is optimized. They can be frozen for longer storage or shipment; in both cases, shock freezing has its benefits, with the products reaching the correct cold temperature very fast, which ensures their properties will keep. The lower the required temperature, the bigger the refrigeration unit will be, comprising one or two-stage compressing units, Peter De Naeghel – Managing Director, iceCool, explains.

Shock freezing with icePower

The icePower shock freezing equipment developed by iceCool can reach temperatures as low as -35°C. Pastries, as an example of notoriously delicate products, are best frozen at temperatures between -25°C and -35°C. Shock freezing timings are set according to the product’s weight; when the process is complete, most products will do best if stored at -18°C.

The freezing speed has a direct influence on the kind of ice crystals that are formed when the moisture freezes inside the product. Fast freezing creates numerous small ice crystals, leaving the cell wall of the products intact. This means that, after defrosting, products will have the original cell structure and retain the original tenderness and aroma. Alternatively, slow freezing creates large ice crystals destroying the product’s cell walls, as the ice expands. In this case, after defrosting, considerable moisture, including important nutrients, will leak from the product, which also loses its firmness. Through a proprietary process, “iceCool installations are designed to guarantee the principle of small ice crystals retaining the fine cell structure and moisture, thus resulting in very good quality and freshness of the product,” De Naeghel details. Custom designs include various tunnel versions, a choice between ceiling or standing evaporators, and countdown systems for each trolley – among others that can be identified on a case-by-case basis.

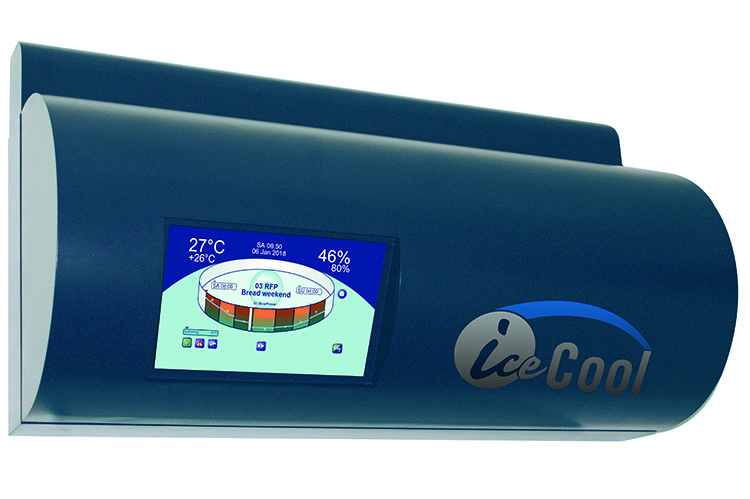

Shock freezing with the icePower equipment can be monitored and closely controlled via its switch box and control panel. “All the electrical switching components are placed neatly and clearly above the entrance door, for easy access for service and operating,” iceCool’s managing director explains. The company uses this control panel and standardized interface for every type of installation, including its freezers, or retarders/proofers. The icePower comes with new smart features, including:

+ Network, backup, remote controlling

Product menus and weekly schedules can be saved and backed up using download/upload functions. iceCool installations can be connected via the four-port Ethernet switch to the local data network, to control installations remotely from the office or via WiFi, from mobile devices. “If you have an Internet connection on your network, then you can control your installations worldwide, via the Internet,” De Naeghel highlights.

+ Error reporting

If the installations are connected to the Internet, possible errors will be reported via e-mail.

+ HACCP log table and graphics

The standard integrated HACCP log table and graphics help with regulation compliance, for the mandatory temperature registration. “The stored data will be kept for more than one year in the control panel and it can be accessed directly for quick analyses – in table or graphic form. The data can also be extracted and saved on USB or via PC-network, directly onto computers,” the specialist details.

+ Hygiene improvements and energy savings

All iceCool installations, including icePower, feature an industrial magnetic door-closing system – the iMagnet, which automatically closes (almost shut) behind the operator, to keep the warm and moist air out of the freezer. “This innovative and robust door-closing system is the newest form of hygienic mechanisms on modern cooling and freezing compartments. It eliminates moving parts that can break or impede the smooth movement of the racks,” he details. Also, there are no obstacles or frames in the way, for easy door cleaning.

The energy improvements help achieve savings for a two-and-a-half-year ROI, iceCool calculates. When an additional swing door is used, there is less ice in the freezer and evaporator, which means that fewer and shorter defrosting sequences are needed. There are multiple additional advantages: improved hygiene while less frequent cleaning is required, shorter running times for compressor and fans are achieved, and the properties of the dough are improved, the company says.

In addition, iceCool is also prepared to offer regulation-compliant refrigerant solutions. Since 2020, refrigerants with a so-called GWP value (‘Global Warming Potential’) higher than 2,500 may no longer be used. Further steps will be introduced by 2030, as part of the EU’s initiative to phase them out. “iceCool has long been using the greenhouse gas-reduced refrigerant R448A, which has a GWP of 1,380 – well below the limit value. Since further steps by the EU are foreseeable, we offer two future-proof alternatives, namely the natural refrigerant R744, known as CO2 (GWP=1) and the future refrigerant R455A (GWP=146),” De Naeghel explains. Depending on the application, both alternatives have their strengths and the company provides consultancy on choosing the correct version.

Energy-saving system

iceCool systems are built to run all year long, in summer just as in winter, which is made possible by the generously dimensioned design of their cooling components. “The pressure build-up is significantly lower than in standard systems. The compressors, including the weightlifter, have to do less mechanical work, which reduces CO2 emissions and saves considerable energy and money over its lifetime,” adds De Naeghel.

The equipment also features the iSave HeatRecovery system, which manages the heat generated during refrigeration. With iSave, this heat can be used in various areas including rinsing or heating water. Thawing and fermentation are among the processes with high energy-saving opportunities.

De Naeghel points out that, “The iceCool heat recovery systems iSaveHeatRecovery can be quoted and supplied by iceCool. In this way, iceCool refrigeration concepts achieve eligibility for state subsidies in Germany when selecting eligible refrigerants and if the requirements for waste heat utilization are still met.

The article is part of an extended feature, which was originally published in [BBI 5 – 2022]. Read the full article in the magazine: