By Catalina Mihu

To manufacture rolls and buns with consistent quality for the lowest possible costs, efficient systems are a must, to produce the required volumes and varieties and provide solutions to any number of production challenges.

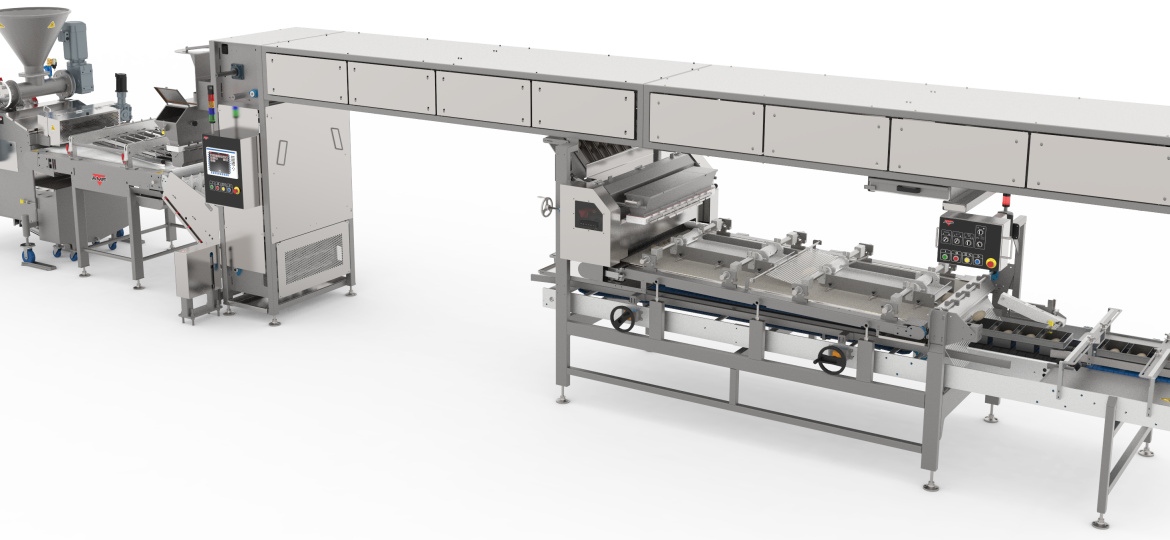

While manufacturing buns and rolls in high volumes is in itself a challenge, having the product variety to meet changing consumer trends takes challenges to the next level, in everything from mastering production scaling to the equipment itself. Operator skill is also essential to maintaining efficiency, and especially so when experienced bakers and operators are hard to come by. To sustain high-volume production, absolute control over each step of the process is a must. Automated equipment is essential for this. Bruce Campbell , Vice President – Global Product Technology at AMF Bakery Systems, illustrates: “When bakers run a 96,000 buns/hour line, that means about 27 pieces are made every second. At such a production rate, the system must be well balanced and must react to variable operating conditions.” To support this kind of system, the company recently developed the AMFConnect data management system, which provides live reports about Key Performance Indicators (KPIs) and Diagnostics. The line also includes a newly-redesigned make-up system, which is now easier to clean and comes with additional food and operator safety features, based on EHEDG guidelines.

The line can manufacture soft hamburger buns, assorted rolls and hot dog buns.

Process control, step by step

AMF designed its high-speed systems for buns and rolls with these challenges in mind, with input from bakers. The line of Accupan Make-Up systems focuses on maintaining constant product quality and safety during production. It can produce rolls ranging from 25 grams to 150 grams. For the production of hot dog rolls, the size range is from 3” (mini hots) to ‘foot longs’ (approx. 300 mm). Special

options can also be produced with Twin Roll Splitters at up to 120,000 units per hour.

In addition to the Accupan, AMF also offers the ComboMat, a make-up system for buns, rolls and bread, which allows bakeries with lower production volumes, operating with one mixing system, proofer and oven, to use a single make-up system.

Based on extrusion technology, the HBDFlex and RollFlex Dividers use patented auger technology and precise pressure feedback control loops to process the dough with a minimum of work. “The FLEX pumps, that are at the heart of these dividers, are controlled by servo drives to maintain excellent scaling accuracy, which can be documented and maintained through the use of the new ‘Gram-Saver’ integrated checkweigher,” Campbell explains, which automatically weighs every fifth row of dough balls and records the weights. High-speed processors analyze the scaling trends and make small adjustments as needed to the divider parameters to ensure scaling accuracy.

The recipe management system in the Accupan allows all parameters to be automatically set, based on the values selected during the initial setup or by using the successful parameters from the previous day’s production. Changeovers can be made in a matter of seconds, by selecting the desired recipe via the HMI. “There are no change parts needed for different sizes or rates of products. Even the swap of molder boards and imprinters can be automated in certain configurations,” Campbell explains. Options that can be set on the HBDFlex Accupan include the auger pressure set point, the UltraFLow RPM, metering pump speed, knife and intermediate proofer speed synch, rounder belt speed, servo gate controls, the speed of the sheeter roller and the molder belt, pan pre-indexing speed and magnetic pan indexer settings, pan shaker settings, and the flour reclaim sequence. All these automated operations contribute to the system’s high manufacturing speeds of up to 72,000 buns per hour per make-up system. The system only requires minimal intervention from operators to run.

The system also features the AMF Fusion Dough System, which mixes and delivers dough at constant rates and temperatures to the AMF Flex divider – this ensures the pieces of dough accurately match the required weights and shapes. The AMF Convay system then transports pans and products, working with smooth transitions through process steps, to protect product integrity.

The AMF BakeTech proofing and baking technologies are also incorporated into the system, and contribute to product consistency by keeping processes under control. The AMF Workhorse system is responsible for the high-speed handling of pans. “This is a key process for balancing the exact pan rate with the production needs,” Bobby Martin, Global Product Systems Leader at AMF, also explains. The buns and rolls are then cooled through an AMF Vesta Spiral Cooler and brought to the AMF PackTech packaging station. At the end of the line, AMF Workhorse and AMF Convay will then team up for handling and loading: plastic baskets and cardboard boxes, which can also run simultaneously, are placed onto the shipping docks via palletizing systems.

HBDFLex divider

FLEX pumps assembly

Extrusion and dividing options

There are two basic AMF Flex dividers available for buns, rolls and English Muffins, with design differences that enhance their efficiency and flexibility based on the types of roll and speeds.

1. The HBDFlex divider is available in 4, 6, 8 and now 10 pockets; Campbell recommends this equipment for high-speed bun production: “The servo knife can run up to 155 cuts per minute. Scaling accuracy is typically a standard deviation within 1% of the target weight. For a 60-gram dough ball, the STDEV is 0.6 grams.”

2. The RollFlex, available in 4, 6 and now 8 pockets uses a single auger pump with built-in dough developer. This is excellent for a bun and roll line that has more changeovers and has products with inclusions like fruits. The RollFlex has two options for augers, 6” and 8” depending on speed and dough types.

The MuffinFlex is a version of the RollFlex, but with a smaller auger, which is specifically designed for the slack English Muffin dough on a raised frame, to feed into a Sugden Proofer and Griddle.

The FLEX pumps on AMF’s dividers use a simple sliding vane technology that can manage the flow of dough from each port with accuracy and low pressure. “The flow is automatically balanced across the ports and using recipe control can be reliably repeated every day. Each pump has its own servo control, which also allows the speeds to be adjusted individually if needed,” Campbell details. More-

over, if a port or two needs to be blocked off (e.g., when a 6-across pan runs on an 8-across bun system), this is done automatically via the recipe management system, by simply setting the speed of that port to zero.

All about the dough

The UltraFlow Dough Developer is critical to achieving consistent dough quality. It is based on the popular DoFlow system, which has been used in the production of buns for almost 40 years. The UltraFlow has received improvements for higher capacity than its predecessor and can run over 15,000 pounds per hour. This production rate means it can even be used on some bread lines. Campbell explains: “The theory has always been to use vacuum to degas the dough just before dividing. This was originally invented for use on Volumetric Dividers, where significant gas built up in the dough over the 15-minute batch cycle. This improves scaling accuracy and also eliminates defects due to large holes from gas.” Additionally, the action of the developer paddle ensures the dough is consistent from the start to the end of the dough batch as it enters the divider, a critical feature for the ultra-high accuracy and volumes needed in today’s QSR market.

AMF has an optional UltraFlow Bypass hopper, which allows the unit to be rolled back and the dough will skip this step in the process. This bypass benefits stiffer doughs and products that need the Accupan to make a more ‘open’ grain look.

left: The AMF Convay system; right: AMF Pan Shaker

Movers and shakers

The S-Series Conveyor keeps products on the move along the bun line, bringing an upgraded sanitary design. “The AMF Convay engineering team was inspired by the highest food industry sanitary design standards, reviewing the design with bakers and continuously making sanitary design assessments. Hollow structures, sandwich catch points and flat surfaces have been eliminated from the design, reducing the sanitation time requirements,” Martin adds. Moreover, the S-Series is configurable based on unique preferences, to comply with specifications for controllers, panel views, motors, bearings, type of levelers, type of carrying belts and type of sprockets. All AMF Convay systems are designed for the application, so trays of any size can be used. “Application engineers will select the proper widths and belt types for conveying dough balls, pans, lids, baked products, packaged products, plastic baskets, basket stacks, cardboard boxes, pallets and pallet stacks. AMF Convay is the brand connecting all AMF family of brands technologies into one complete system,” he explains.

This bun and roll line also caters to the QSR manufacturer’s needs by incorporating a pan shaker, which centers the buns with a simple, linear shaking motion, to eliminate the risk of defects in the products’ shape. “The AMF Pan Shaker design is unique as it allows up to 10 shakes for each pan, while also never stopping the pan. The high-frequency shaking action can also eliminate doubles if one dough piece is overlapping another when they initially reach the pan,” Campbell explains.

Cool, cool

Time is money, especially so in high-speed bakery production. All process steps, and the connections in between, run at a similarly fast pace on AMF’s bun and roll line. This includes pan and product cooling. For pans, cooling allows them to reenter a new production cycle faster, saving time, and money. The line specialist incorporated the AMF BakeTech pan coolers to help here. The system, on the one hand, protects the fresh and cool dough pieces from the heat of the pans by either allowing the pans more time to cool at ambient temperature or by speeding up their cooling process with controlled airflow in a tunnel. Cooling products, on the other hand, takes into consideration the bakery’s location and environment; some can constantly cool buns and rolls, throughout the year, with an AMF Vesta Spiral Cooler running at ambient temperature and humidity. But, for bakeries where the ambient conditions within the production area change with the seasons, a fully controlled environment is key; here, the AMF Vesta Spiral Cooler Enclosed option helps control both humidity and temperature, maintaining values within the same range all year long, regardless of weather changes.

Once cooled, the buns and rolls are ready for their last stop: packaging. Products are automatically brought to the packaging machine with another conveyor system, which offers several handling choices. Martin explains: “AMF Convay has developed many different solutions for handling individual products with round, square or oblong shapes, as well as for clustered products of many cluster configurations. Once products are delivered to the infeed of AMF PackTech packaging machines, the products are accumulated making sure the packages are filled with the exact number of products, and then automatically released to the continuous sequence of slicing, bagging and tying machines.” AMF PackTech technologies automatically deliver packaged products at a constant rate downstream to the AMF Workhorse product loading station.

Conclusion

Over the past decades, existing technologies have been constantly challenged by high consumer demand. That has put pressure on engineering teams to develop faster units and more reliable equipment, running at more than 99.5% run rate, Martin points out. Higher production speeds brought about new challenges, as the impact of food waste impact grew simultaneously. “The oven is often declared as the heart of the bakery, and rightfully so; but, industrial bakers recognize the importance of the whole system running at cruising speed,” he says, acknowledging the importance of having automated, continuous operations and keeping up with consistent quality, with the support of data collection and machine learning capabilities.

For fully-automated bakeries, the AMF LineGuardianTM brings a network connection, providing real-time dashboards from all AMF NexGen equipment built on AMF Connect specifications. Martin: “The interconnectivity of all the units reporting real-time status is the future of industrial bakers, helping them make decisions based on data and trends.”