Low moisture, long shelf-life, diverse sizes and shapes – crackers and cookies are a segment filled with opportunity. Their characteristics also dictate process improvements and how equipment can support optimization.

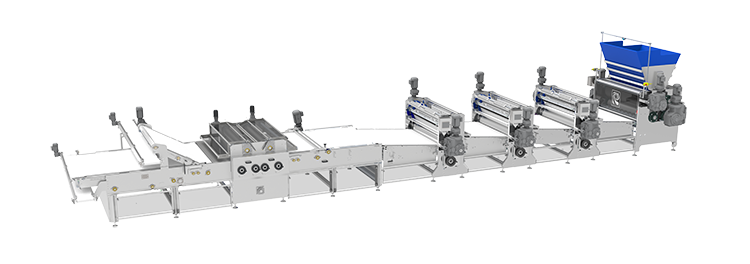

Every step of the manufacturing process contributes to perfecting production. For crackers, techniques can range from working with straight, dual-sheeted or laminated dough. Baking is then key to finding the perfect balance between reaching adequate moisture content, the right color and a stable product that will reach the consumer intact. The automated cracker line developed by Reading Bakery Systems (RBS) can process fermented and unfermented cracker dough, biscuit dough and other products. The company recently completed a redesign of their sheeting system, focusing on a modular design, so it can be built starting from a base machine model, onto which functional upgrades can be implemented, according to specific plant operational needs. In this way, the system can receive add-on features and upgrades after installation, to adapt to production changes.

The redesigned sheeting line incorporates several new features aimed at making it easier to operate and more flexible. Among the notable new developments, RBS highlights ‘high-visibility’ guarding that helps get a clear view of the process areas, endless belt replacements for conveyors, and removable roll scrapers, for sanitation and maintenance operations. The remote input/output system has also been improved to simplify the electrical requirements of on-site installations, while also lowering the amount of wiring required to connect individual machines to the main control panel.

Endless belts help minimize downtime, as replacing them is performed in a matter of minutes, while also simplifying the machine. “This design also includes an easier way to release scraper blades to simplify cleaning procedures,” RBS points out.

The unique characteristics also include roll skewing, which is available on the final gauge roll. This was added for increased control of the dough sheet toward the edges, without the need for product-specific roll tapering, the company details. The new system also includes RBSConnect, the company’s latest custom control systems. Energy efficiency is also continuously monitored, from motor loads to electrical system loads. The system provides graphical trends and sends notifications about potential/upcoming maintenance tasks.

For further process optimization, load cells can be utilized on the gauging and rotary cutting processes to monitor machine loading levels. “Machine loads can vary depending on the consistency of the dough being processed, but any irregular forces measured will alert operators. Those flagged values will display on a trend screen to pinpoint undesirable process deviations or incorrect manual adjustments,” explains the line’s manufacturer. Product trends are also available, to generate notifications of changes such as dough quality and gaps in production.

“The new features allow an even greater variety of doughs to be processed, such as gluten-free or products with more ‘exotic’ ingredients that were previously very difficult to produce. These rotary-type forming systems are somewhat limitless in their outputs, so the only limits in production speeds are set by the oven size,” explains RBS.

“These new features allow an even greater variety of doughs to be processed, such as gluten-free or products with more ‘exotic’ ingredients that were previously very difficult to produce.”

Reading Bakery Systems specialists

Focus on hygiene

At the same time, the upgraded line addresses heightened market concerns over hygiene optimization throughout production plants. To this end, quick-access panels were added, for easier sanitation and maintenance. Moreover, including unobstructed views into the new design of the machine allows operators to better visually inspect, assess and plan downtime for line sanitation or maintenance.

This new sheeting line was also designed to prioritize hygiene by including fewer components, to minimize the parts that need to be removed to clean and maintain. In this way, both the cost and the workload required to clean the machine are reduced. “Designing more toolless access and decreasing the total width of the line for better access were important goals that were set for our design team to improve the user experience,” RBS details.

The blueprint

The cracker line from RBS comprises all process steps, from mixing, dough handling and forming to baking and drying, as well as additional steps that may be required. Continuous mixing is the preferred technology for this line, covered by the Exact EX Continuous Mixer, an automated system that can work with doughs with various hydration levels, with production rates ranging from 100 to 10,000 kg per hour.

Next, the Thomas L. Green 3-Roll Sheeter or 4-Roll Sheeter generates a consistent dough, which is instrumental to packaging efficiency, after baking the crackers. The thickness of the dough is controlled by adjusting the distance between the rolls. The sheeter can range from 600 mm to 1.6 m in width, with production volumes starting from 200 to 5,500 kg/hr. The dimensions are determined by the oven’s length and width as well as by the characteristics of the product. The resulting dough sheets are ready for lamination if required. The laminator ensures product consistency by accurately placing each sheet so that the sheet has the same dough density throughout its surface.

The Thomas L. Green Prism Oven is the centerpiece of the line, in charge of baking and delivering consistent product characteristics. Cracker oven zones available include direct gas fired and convection. For maximum efficiency, hybrid and electric ovens are available. Each of the zones can be controlled to precisely combine heating modes for specific baking effects and timings. Optionally, fans, topping units, or thickness sensors can also be added, depending on the product and process requirements.

Wirecut cookie technology

For wirecut cookies, the Thomas L. Green WCX wirecut machine from RBS also includes newly-developed upgrades, focusing on flexibility, control, safety and sanitation. The R&D team looked at challenges traditionally met with this type of technology, from difficulties in handling different dough viscosities and compositions to difficult changeovers, complex maintenance and cleaning operations.

RBS’ solutions for these issues are bundled in the WCX Wirecut Machine that was introduced at IBIE 2022. Its product range was expanded to include standard and filled bars, multi-color products, filled and encapsulated cookies, pet treats and frozen dough applications. The system’s modular design supports this, as well as a wide range of optional equipment that can be integrated. This flexible setup allows multiple configurations, according to the desired product ranges. The WCX Wirecut Machine was also designed with fewer parts – it has 50% fewer moving parts than standard wirecut machines, RBS says, which simplifies maintenance. The head is removed from the side of the machine and manually rolled onto a sanitation cart, for cleaning, without the need for a crane.

The WCX offers several ways to co-extrude cookies and bars. With optional attachments, two doughs can be combined to create products with varying colors, flavors, and textures. 3D-printed die cups can expand diversity even more. In addition, products can be filled with various co-extrusion materials. Less viscous materials such as jelly fillings can be pumped into the wirecut head with an optional external pump.

To ensure safety, the WCX machine uses a light curtain system that surrounds the machine. When the curtain is ‘broken’, the machine immediately shuts down. In addition to enhanced safety, the light guard system maximizes access to machine components for easier maintenance or wash-down.

Process consistency

The WCX can produce throughput yields of up to 300 cuts per minute (cpm). It cuts individual shapes uniformly using a removable wirecut harp assembly. “Combined with recipe-driven linear servo motors, it can be programmed with a virtually unlimited number of cutting profiles,” RBS says. The profiles include cutting position, stroke length and cutting speed, which can be adjusted without having to stop the machine. Custom-designed die and wirecut assemblies are created for specific product characteristics.

An optional ultrasonic cutting attachment can be used for materials that are more difficult to cut or separate. Applications that commonly cause wires to break, sticky products, or those that contain raisins, oats, nuts and jams are best cut using an ultrasonic cutting blade, RBS recommends. On the WCX, ultrasonic units are mounted below the die cups, replacing the wireframe assembly.

For additional product flexibility, an internal pump and iris cutter are also available. The internal pump ensures consistent flow, while the iris cutting system separates and encapsulates the cookie. The iris cutter is recommended for use on premium cookies as well as cutting or crimping filled cookies. With a maximum rate of 40 cpm, this integrated cutting system is mounted beyond the wirecut machine on the transfer conveyor frame. With these upgrades, the door is open to future developments: “For manufacturers who operate with traditional wirecut technology, the material difference between soft biscuits, cookies, ingredient-dense snack bars and gooey filled products has always meant changeovers, undesired downtime and slowed production. Today, the technology present in the WCX Wirecut Machine has the potential to create a whole new kind of changeover — a one-time switch to the ideal dough-forming platform,” the company anticipates.