Ensuring the correct proofing conditions and timings is a key step in dough development. For heavy-duty processing with consistent results, various technologies of industrial proofers accommodate the needs of the dough and the plant itself.

There are different technologies available for setting up automated industrial proofing, from rack, tray and step proofers, to continuous equipment – all of which provide control over the key process parameters: temperature and relative humidity.

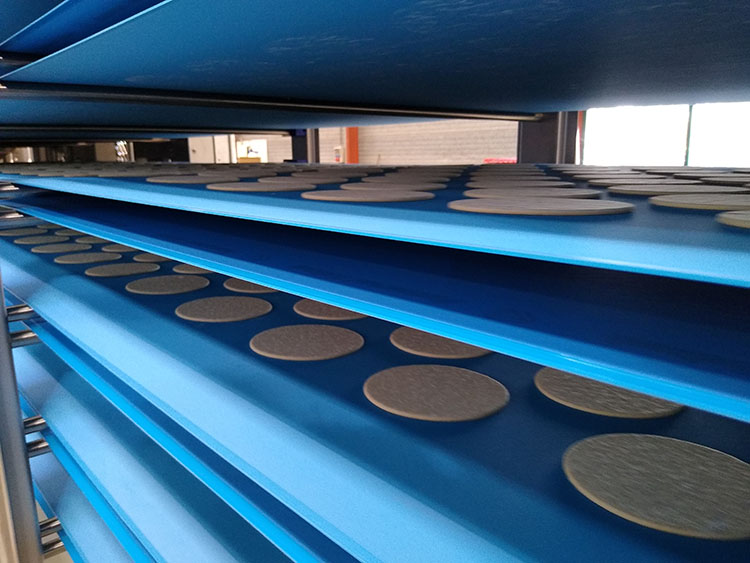

Rack proofers, for example, provide a compact solution suitable for limited floor space. AMF’s Vesta Automatic Rack Proofer is designed around the required specifications of the racks and shelves, with interlocked, hinged access doors on both sides for rack maneuvering. Its latest design improvements started with its structural materials, for a more sturdy construction. It uses heavy-duty aluminum racks, also with durability in mind, as well as (removable) stainless steel grids, which also stand in for center support. Its PLC-control proofing system helps provide the optimal combination of temperature and humidity over time. A cooling damper can be used to mitigate over-proofing and offer flexibility in timings for the next production steps.

Alternatively, spiral technology is at the heart of continuous processes, including proofing. The Vesta Spiral Proofer, also manufactured by AMF Bakery Systems, was designed for easy cleaning and maintenance operations. Sanitary design elements include a patented monopiece cage bar, which provides access for installation, cleaning and maintenance, the use of modular plastic belts incorporating the Intralox DirectDrive™ System, and its full wash-down construction. Its enclosure is easily assembled, AMF says, and helps control airflow. The optional conditioning humidity unit ensures uniform conditions for consistent proofing results as the dough pieces are traveling through the belt proofer. It incorporates the AMFConnect suite, for automated data tracking and management.

When proofing is done directly on the belt, the peel-off synthetic belt conveyor gently transfers proofed products between the spiral and conveyor and a scraper removes any remaining dough before new pieces come in. When products are going into the spiral proofer in pans, guides position them correctly, and inserts on the belt ensure any type of pan securely stays in place until it is ready to be discharged.

Optional features can further simplify working with the Vesta: an internal drum access platform can be added for maintenance, in addition to the conditioning unit. Remote VPN access can be incorporated for machine troubleshooting and data monitoring.

Weighing all options

To select the best technology from the available options, several factors should be considered, AMF lists, from the required capacity, product variety, the desired level of automation. “These are factors with a great deal of variety,” the specialist points out, which is why the optimum solution is always a tailor-made one. Costs are also a determining aspect, especially for medium-sized production lines, so the initial budget and the ROI are taken into consideration in the design. “AMF’s proofing system is very flexible and modular, so we can adapt to any bakery situation and challenge. These can range from entry-level production bakeries that are entering the automation arena for the first steps in scaling up their process, to large-scale operations with long continuous runs, where stability, quality control and throughput are key performance indicators,” the company says. In all of these cases and their respective proofing technologies, the environment inside the enclosure is maintained at constant temperature and humidity until a change is made, so every product within the proofer is exposed to uniform process conditions.

Certain features were built into AMF’s proofers to facilitate their operation: automatic washers are used for sanitation within the proofers, and dual conditioning systems are also available as a backup, in case one system is not working or is in service mode.

For best results

Since only one set point of temperature and humidity can be maintained for uniform proofing, recipe control and preparation are key to identifying the optimal proofing conditions. If different types of dough can be proofed with the same parameter settings, they can be proofed together seamlessly. Alternatively, If products require significantly different proofing conditions, then the settings need to be adjusted for the new product’s profile before the next batch enters the proofer, AMF recommends. AMF’s proofers provide product tracking so the operator always knows which products are in each stage of proofing.

To adjust the capacity of the proofers, AMF suggests changing the dwell times. Process optimization, on the other hand, requires balancing several process parameters, including a consistent climate and the speed of the belt – for belt-proofers. AMF explains the process behind optimizing proofing efficiency: “Compressed air and filtered cold water are mixed and atomized to produce fine cool droplets that travel through the heating coils to reheat the air and filter any droplets that have not turned to humidity.” Calculation models at AMF also include pan sizes, their travel direction, the number of pans per minute, required times, pan and weight, and the weight of the belt itself. The result of the equation must be identical dough development throughout the proofing system.