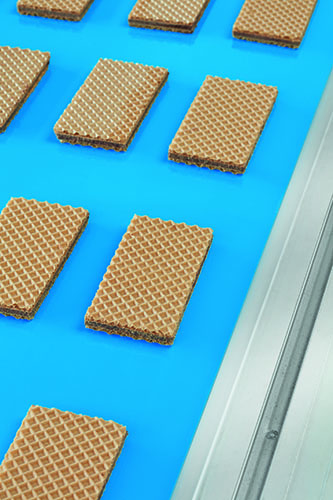

With the ‘Siegling Fullsan’ product range, Forbo Movement Systems has launched new homogeneous conveyor and processing belts made of TPU (thermoplastic polyurethane) particularly for hygiene-sensitive applications.

Everyone in charge of the processes in food production is directly interested in avoiding any hygiene risks. Product contamination, whether with bacteria, foreign bodies, or other impurities, could ultimately have incalculable consequences.

Hygiene for conveyor belts

According to Forbo Movement Systems, homogeneous belts have become indispensable primarily because they withstand all thermal and mechanical challenges, and are also easy to clean and resistant to the chemicals used in cleaning. In addition, homogeneous belts are completely sealed, the company says, and therefore allow no access for contamination with oil, grease, moisture and bacteria. Moreover, they are also UVC-resistant, making them suitable for regular sterilization with UVC irradiation.

The newly introduced Siegling Fullsan products are the reinforced ‘Pro’ version (FLT+) of the ‘Flat’ series, with embedded aramid cords running lengthways. The cords increase the tensile force and minimize belt elongation, which makes these belts particularly suitable for longer conveying distances and larger loads. They are designed for use in the baking industry, dough processing and snack production, among others, and comply with the current FDA and EU regulations.

The new additions bring the company’s portfolio to four variants:

+ A FLT+ with a matt surface for accumulation operations or the transport of dry and packaged products,

+ A version with a smooth, glossy surface with good cleanability for applications with moist products, and

+ Two versions with a negative pyramid structure (NP structure) on either the top or the bottom side of the belt. The NP structure on the top (on the carrying side) improves the release properties. This is particularly interesting for conveying fatty or sticky types of dough and can reduce the need for flour as a release agent, according to the manufacturer. The NP structure at the bottom (on the running side) reduces the friction value of the belt to the table. This saves energy and the belt hand handles additional loads.

If frequent cleaning cycles are necessary for a process, Forbo recommends the reinforced FLT series as it brings additional benefits for the user due to the hydrolysis resistance of the belts and the resulting increased service life. Another advantage is said to be the high k1% value with low elongation at fitting. The high k1% value enables a significantly higher loading of the belt compared to commonly-used, non-reinforced versions and guarantees high dimensional stability.