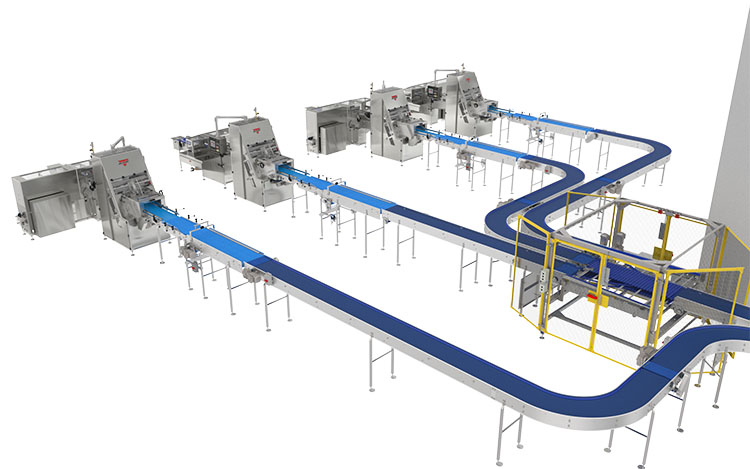

To maximize the benefits of automating bread slicing and bagging, industrial bakeries need to keep their customization options open. Aside from processing speed and reliability, flexible and easy adjustable equipment is a must.

AMF Bakery Systems looked into slicing, bagging and streamlining both processes with the Combo Bread Slicer and Bagger, which was designed to process a variety of pan breads. This machine can cut slices ranging from 92 mm to 140 mm in width, with a height of 76-152 mm and 203 mm to 432 mm long. The lattice allows slicing from 9.5 mm to 15.9 mm. It features a Hansaloy lattice, mounted on a mechanism that slides out partially or can fully extend, to allow the lattice to open evenly across the entire width of the machine. Chromed blade backing rollers maintain blade stability through the slicing process.

To switch between different products for slicing, recipes can be accessed through the product menu, with preset guides and slicing parameters. In addition, “Out-of-box equipment can be also adjusted using manual handles, or electrical knobs. The HMI will maintain the initial setting until the recipe is adjusted with a new value,” AMF Bakery Systems explains.

The system is equipped with a pendulum-style scoop drive, to minimize vibration during operation. Different pan or bag sizes may require changing scoops. An operator will be able to swap them out in about a minute, AMF explains. They are equipped with handles so they can be easily manipulated.

The 75S Slicer and Bagger units can process pan breads ranging from varieties with wheat, wholegrain and fruit dough. Supporting such variety also means special attention needs to be paid to the system’s sanitation. Depending on the intended usage, an optional blade and drum cleaning system can also be equipped – it can be used for fruit or gluten-free breads, for example. Certain product recipes can automatically activate the steam or water features, as well as blade oiling.

A straight in-line product flow design was preferred for this system instead of a 90° transfer, to allow easy handling and access around the equipment. Products are fed into the slicer and bagger via a continuous, high-speed conveyor.

Over and out

For bagging, a scoop system that brings the bag over the bread is used, to protect the package from damage that might occur if it touched the sharp edges of crusty loaves. The bagger uses the pendulum technique to bring the bag over the bread. “Our pop-up patented flight moves the bread from the slicer and electronically times the operation with the pendulum and scoop to capture the loaf and slide the bag over the bread, while top and bottom scoops are holding the bag. The pusher keeps the loaf stationary during this operation. As the scoops move back with the pendulum, the bag lands safely on the flusher belt,” AMF explains the bagging process. Two removable crumb collection slides can be included under the conveyor to collect the crumbs and reduce sanitation time.

Access to the machine and operator safety were both considered in the design of the bagger. With the new concept, the infeed and discharge conveyors do not have a protective guarding around them, to allow visibility of the process and products. This open design allows for the removal of non-conforming products or placing loaves on the conveyor without having to open a hatch and interrupt the equipment. “AMF’s concern for the safety of the operators required the design of a conveyor with pop-flights, to remove the cages from the conveyors. These patented pop-flights removes the pinch points. They have the property of bending and disengage from the chain if the operator’s hand encounters it,“ the specialist explains.

Extra features

The slicer and bagger system can be further automated with additional features, including:

+ Automatic pressurized oiler system – designed for low-fat or gluten-free loaves, it automates the daily lubrication procedure of the felt pad. This kit includes the pressurized manifold, oil bottle and HMI screens. The bottle should be filled with oil (mineral or vegetable) and delays should be set up for each recipe. Alternatively, a manual cycle can be run. The oil will be sprayed evenly on the blades and lower/upper drums.

+ Automatic water spray system – designed for a raisin/weight ratio of under 20% and short batch production runs of raisin bread loaves (less than 2 hours). This kit includes the water spray nozzles, catch pans and HMI screens. A drinkable water line must be supplied to the slicer. Delays can be set per recipe for it, or a manual cycle can be run. “This system will avoid any stoppages for cleaning during the production run. Deep cleaning will be required at the end of the production run to avoid fruit gum hardening on the blades and drums,” the specialist recommends.

+ Automatic steam cleaning system – designed for a high ratio of raisin/weight, from 20% to 50%, or the continuous production of raisin bread. This kit includes the steam manifold with spray nozzles, the steam valve, a piping heat protective shield, catch pans and HMI screens. The slicer will require a connection to dry steam. This system also requires deep cleaning at the end of the production run to prevent fruit gum from hardening on the blades and drums.

+ Automatic blade tensioning – it uses a proportional–integral–derivative (PID) controller to secure the blade tension and optimize its lifespan. It also detects broken blades.

Process control

Just like the slicer, the bagger also has an automatic product changeover feature, which can independently adjust the infeed, lattice height and discharge guides. Optionally, the bagger can be equipped with a pendant arm to allow the staff to operate the machine from different positions.The slicing and bagging processes can be monitored via the single-swivel operator control panel.

Every process parameter can be controlled via its new interface, which also provides data on the machine’s performance. The operator can switch the screen between the slicer and bagger menus via the swivel option. A ‘skip loaf’ option is available and can be activated to manually insert a loaf on the bagger infeed. Preventive maintenance can also be scheduled here. Data about most active components can be accessed on the screen, to support maintenance planning. With the design of the system, AMF aimed to ensure the balanced flow of the overall process.