Pies have the magic ability to reinvent themselves with the fresh flavors of every season. But, precious nostalgic memories make them an even more cherished dessert. Creating infinite variations is a great business strategy for such a deeply personal product – as long as it is done efficiently.

Fruit pies with changing flavors throughout the year, seasonal meat pies, or trendy pasta del nata, hoop pies and quiche – few products offer such a diverse palette for creativity. Whether the pies have an open top – covered with various ingredients, or are closed with dough, lattice, or crumble, the technology needs to produce excellent results no matter the recipe and material changes. Variables do not stop here, either: pies can be made on different supporting surfaces/containers, from foil to paper to metal baking trays, hoops, tins, or indented trays.

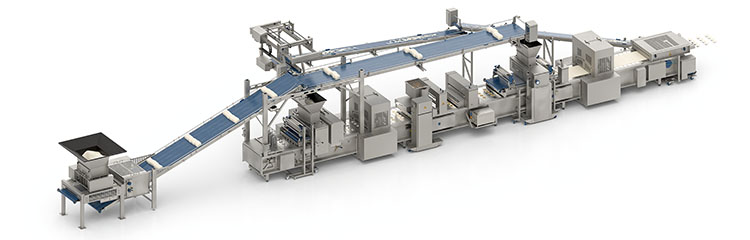

The Rademaker Pressing line is engineered to produce an extensive assortment of pies and quiches, covering international cuisines, baking traditions and new product innovations, without configuration changes. When the product size and shape change, for example, the product change-over parts will change to match the new recipe in production: the platterns and blocking dies need to be

exchanged. However, the line configuration will stay the same.

When a different product entirely starts running on the line, the process changes are related to the size of the pie as well as the type of filling being used. “Depending on the filling type, it could be the case that different nozzles are needed, or a different type of depositor. Changing a

depositor is easy because they are constructed on mobile frames, which makes it quick to swap in and out of the production line,” said Wouter van der Veek, Product Manager. Changing from savory to sweet pies is also possible: technically, it translates into simply using the desired type of filling.

A crucial consideration when dealing with such a vast product variation, which often includes premium, limited-edition and seasonal items, is production capacity. “When employing an automated process for making pies, optimal planning of products and runs, will make or break any business,” van der Veeks observes. Carrying out multiple toolset changes frequently can become timeconsuming. Alternatively, ensuring small changes are made throughout a production day ensures that the downtime of a line is minimized.

Piston depositors

For filling types with fruit inclusions, the most important aspect is to make sure that the fruit inclusions are not damaged when they are processed though the depositors. In case large fruit particles are required in the filling, Rademaker integrates its Piston depositor. It is designed to handly chunky fillings without damaging the particles.

To optimize production on an automated line, planning can also be optimized with regard to changes in types of dough and pie recipes: processing a single kind of dough per day eliminates the need for changeovers in strip feeders and rolls. Moreover, cleaning the mixers and ingredient handling equipment is not necessary when a single recipe is in production, improving the bottom line. Other aspects that should also be considered for production planning include using different types of fillings, which should be scheduled by color, or allergens they (may) contain. Sorting production sequences correctly can save additional time.

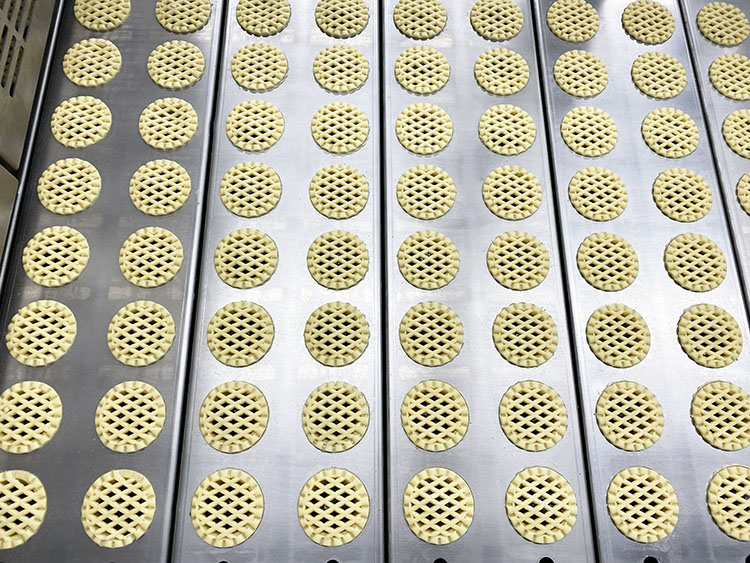

Decoration is an important part of pies, too – one that further adds to their diversity and is often a purchasing decision-maker. Rademaker’s lattice unit can create the decoration pattern in the length/width of the dough sheet, in customizable shapes.

”When employing an automated process for making pies, optimal planning of products and runs, will make or break any business.“

Wouter van der Veek, Product Manager, Rademaker

All about the fruit

Fruits come in greatly different shapes, sizes, consistencies and textures. As pie ingredients, they are used both fresh, portioned into pieces, and made into jams. For fruit inclusions and all fillings in the fruit family, the first priority is to ensure that the fruits are not damaged when they are processed with the depositor.

The adequate depositor is selected to deposit them onto the pies according to their viscosity, consistency and the required accuracy for each filling and end-product. Available options range from Spot depositors to Mohno pumps and Gearwheel depositors, which are used in combination with nozzles that can have both ‘shut off’ and ‘blow-off’ functionality, van der Veek points out. In some instances, ‘shower head’ nozzles can also be employed, to deposit materials through multiple outlets over the surface of the pie. “When large fruit particles are required as a part of the filling, we integrate our piston depositor, which is designed to handle chunky fillings without damaging the particles. For fillings with higher viscosity, we can select a different depositor, specifically designed for this category of materials,” van der Veek illustrates. The Mohno pump depositor is a versatile solution, as the system can handle a wide range of fillings, meaning that it can be used for various processes and product ranges.

New technology developments

Automated quality control is becoming increasingly important as workforce challenges continue to grow. Rademaker’s depositing technology provides solutions that enable high accuracy in processing, consistently: “Servo controls with recipe management, combined with smart algorithms allow the equipment to follow specific parameters for each individual ingredient in a repeatable manner. This ensures that bakers minimize their give-away and provide high-quality, repeatable products,” van der Veek explains.

Servo controls offer optimum control of position as well as motion. For example, servo control of a main production line ensures the proper positioning under the unit operations and is critical if the line is required to run multiple sizes. Digital line control, whether plc- or pc-based, is a given in any new-generation technology, where recipes can be selected and run automatically. Performance data is also collected and analyzed, for continuous improvements.

With efficiency operations entrusted to automated technology – and the production minutely set up, bakers can focus on the creative work for the next delicious pie.