By Andrew McGhie, Global Business Development Director of Vision Systems, KPM Analytics

Emerging machine learning applications take the guesswork out of quality control.

Artificial intelligence (AI) in manufacturing is no longer a fascinating idea – it is already here and accelerating quickly throughout many industries, especially in the baking industry. Several reasons are fueling this revolution.

Firstly, the baking industry landscape has changed dramatically in recent years. Personnel is proving to be one of the hardest challenges. Experienced bakers are leaving the industry, whether it be retirement or seeking a new career path. This exit of knowledge and production know-how, combined with generally high turnover of staff and difficulties in recruiting, have put pressure on industrial bakeries. This trend has led baking companies to consider more automation, process control, and quality inspection.

Additionally, demands for the highest quality and consistent products from customers have never been higher. Quick-service restaurants (QSR) and foodservice customers are fighting for a larger share of their respective markets. They have always been the leaders in setting demanding quality specifications for their products that require constant vigilance and innovation from the bakers. Baked product consumers also have many brands to choose from and are becoming more discerning. These consumers pay attention to the quality of products and are much quicker to select another brand.

There is good news for bakers: recent advancements in baking process control and inspection technologies have arrived, with AI as a critical driver in improving capabilities and simplifying implementation for some exciting applications.

Enhancing rule-based inspection

Over the last few decades, many baking operations have integrated vision inspection technologies to optimize product quality. These systems incorporate high-speed cameras with imaging software to detect and measure food products for important visual traits. They can provide an unprecedented level of information on the quality of 100% of the products that are being produced. For the first time, bakers can have a complete view of the range of variability of their production processes and can start imagining how to minimize that variability.

Bakery plant operators manually program most vision systems today with specific tolerances for the different product traits being measured – a ‘rule-based’ inspection method. Key product attributes such as 2D shape, 3D height/volume, bake color, topping coverage, etc., can be measured using the inspection technology. Using the inspection data to understand the variability in the production process, the final quality specification is negotiated between the bakery’s quality assurance and production teams and agreed on with the customer. This specification is then implemented into the inspection system as the parameters used to determine the acceptability of the product. Additionally, many integrated inspection systems include automatic rejection to remove products from the processing line if their measurements do not meet the rule criteria.

Most bakers have found success with rule-based vision inspection technologies. These systems remove subjectivity from the inspection process. When continually supported by the baking plant’s quality assurance and production personnel, they can generate a fast return on investment. This is through better control of the production processes and improving quality, reducing waste and the opportunity to remove products with dark spots, light spots, and potential foreign materials in order to avoid costly customer complaints and possible product recalls.

The processing power for vision inspection technologies has evolved dramatically in recent years, enhancing capabilities. Whereas most vision systems initially measured only a handful of attributes, some bakeries now measure 30 to 50 different product attributes with their inline vision inspection systems at much greater product throughputs.

These improved capabilities now include the development of new machine learning. AI is now deployed to amplify the inspection system capabilities to measure more visual attributes and to detect more subtle defects. It is also being used to interpret the measurement data and to automatically control different processes in the production process – vision process control.

How is AI influencing vision inspection processes today?

AI is still in its early stages, but three strong use cases are being implemented in baking operations today. The first is through automatic learning and classification of product attributes that can help simplify system setup. In this process, the AI application is presented with many images of acceptable and unacceptable products. Using supervised or unsupervised AI learning allows the inspection system to ‘learn’ what product attributes are acceptable or unacceptable. From this AI learning, a range of tolerances can be set in a much more holistic way. In many instances, the AI application can be expanded to include the communication and control of the production equipment.

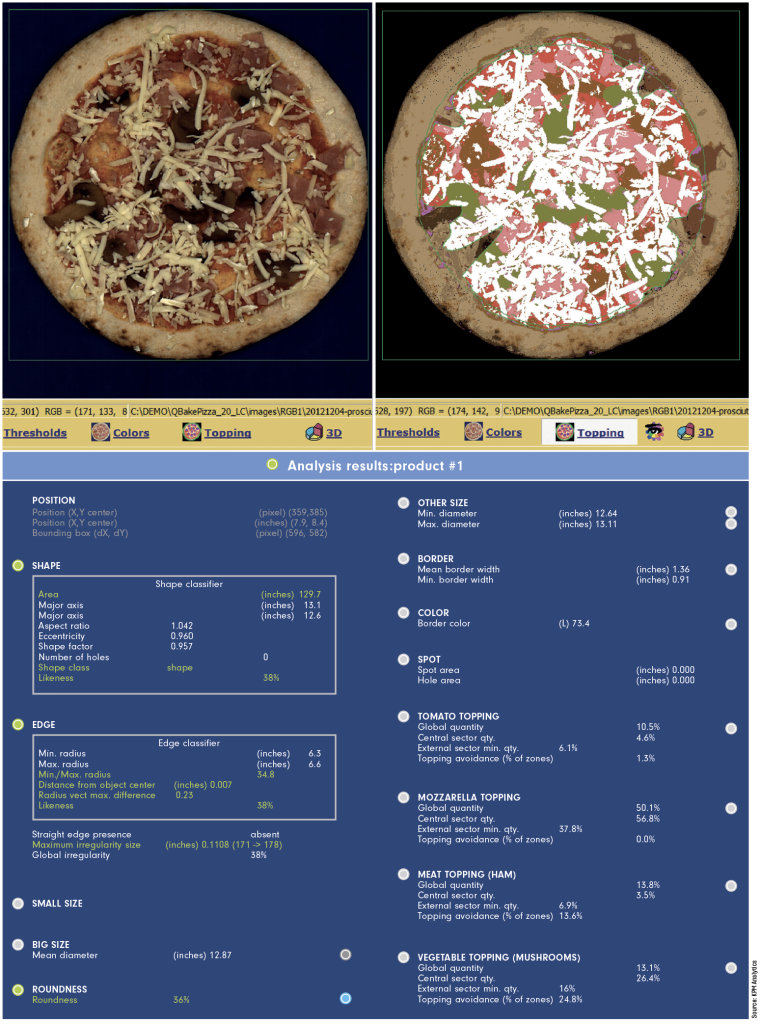

With AI-enhanced vision inspection, topping distribution and coverage can be calculated down to the finest detail, ensuring each pizza meets visual expectations for quality and consistency.

A great example of this automatic learning and classification concept is product topping presence, distribution, and control. Take a finished pizza manufacturer, for example. Customers expect to have their pizza topped with the right number and distribution of pepperoni slices as well as having tomato paste, cheese, and vegetables in the right quantity and distributed uniformly across the pizza. Most pizza operations have these toppings applied to the pizza crusts as they move on a conveyor through the topping applicator stations.

Many pizza lines have very high throughput, run at high speed, and are very wide (four rows wide), making it difficult to do the monitoring using operators standing at the side of the line.

However, an AI-driven vision system can inspect 100% of products on the line and can instantly identify any issues with topping not being present, not being present in sufficient quantities, or not evenly distributed. The sophisticated AI is able to reliably detect and distinguish similarly colored ingredients like red peppers and tomato pieces by looking not just at the color of the ingredient but taking into account the shape, appearance, and texture of the ingredient. This is a significant improvement over traditional vision, which relies solely on color differences. Also, because the AI system constantly learns with each pizza inspected, this ingredient detection capability improves with time.

”With an AI vision system equipped with AI models to detect foreign materials on the product’s surface, bakeries can implement a powerful application to inspect every product on the line for even the most challenging foreign materials.“

Andrew McGhie,

Global Business Development Director of Vision Systems, KPM Analytics

It is nearly impossible for a human inspector to identify and correct an issue with the pepperoni applicator in a timely manner to minimize defective products reaching the packing area. The AI function of the pepperoni can not only identify an issue quickly, it can also communicate with the pepperoni slice applicator machine to change parameters to address the issue or, as a last resort, set off an alert or automatically redirect products that don’t have enough pepperoni slices to a re-work conveyor.

Well-trained AI vision systems can detect subtle anomalies and defects in specific baked goods, such as pieces broken off animal-shaped crackers or cookies.

A second developing use case for AI in baking processes is enhancing anomaly and defect detection. Take, for example, an animal cracker production line – each cracker has detailed features that identify it with a specific animal. Too many broken crackers that make it through the processing line and into the product packaging will reflect poorly on the brand.

However, with an AI vision system trained to inspect 100% of the biscuits or crackers leaving the oven or cooling zone, these shape recognition and defect detection capabilities can be very reliable and used to drive a rejection mechanism to remove defective products from the line. As a biscuit or cracker passes under the camera, the AI system first discerns what type of animal the animal cracker is supposed to be. It then determines if it is missing any features and to what degree. If an elephant is missing its trunk or a bird is missing its beak, the AI system can make that determination faster and more consistently than an average product inspector. The baker also has the ability to determine and set as a rejection criterion how bad the defect needs to be before the biscuit is rejected.

Then, a third core use case – and one that is critically important to baking companies – is AI inspection’s ability to enhance foreign material detection efforts. Foreign material can be something as simple as a dark spot (carbon, dirt, or grease) or light spot (excessive flour, unbaked dough, etc.) or a true foreign material such as part of a blue rubber glove, a broken bit of belt, or blue plastic from the wrapping of a shortening block. Each product recall due to harmful materials finding their way onto the product or in the packaging can severely impact a bakery financially and create an uphill battle to regain consumer trust. X-ray systems do an excellent job of detecting dense objects but are less effective against objects like paper, plastic, films, and other equally harmful objects that can be difficult to see.

However, with an AI vision system equipped with AI models to detect foreign materials on the product’s surface, bakeries can implement a powerful application to inspect every product on the line for even the most challenging foreign materials. It is also common for the bottom of the product to be inspected as well as the top, increasing the likelihood of any contaminant on the surface of

the product being detected and then rejected from the product flow before the product is packaged and sent to the customer.

Another emerging foreign material detection method, hyperspectral imaging, provides further capability to detect objects on the product’s surface by combining visible spectrum imaging technology with near-infrared (NIR) and up to short-wave infrared (SWIR). Hyperspectral imaging offers extra assurance by detecting foreign materials that manual observation can rarely identify.

AI is at the forefront of a transforming industry

Integrating AI-driven vision inspection systems is just the beginning, with future advancements likely to push the boundaries of automation, quality control, and production efficiency. Bakeries that embrace these technologies will enhance their operational capabilities, cope with an unstable workforce, and stay competitive in a market that increasingly demands precision and consistency. As AI becomes more sophisticated, we can expect the industry to move toward fully autonomous production lines, where minimal human intervention and product quality reach unprecedented levels. The future of baking lies in the seamless fusion of technology and tradition, paving the way for innovation and excellence in every bite.