Providing excellent-tasting products is a must, but the eating experience is only one of the goals for successful snacks. The challenge lies in balancing health benefits, clean-label compliance, and manufacturing efficiency – all while meeting consumer expectations.

The challenges of clean-label snack development

Developing clean-label snacks is not a simple NPD project. Several challenges stand between a concept and a successful product. Clean-label recipes avoid artificial additives, preservatives, yet they must still deliver the desired shelf life, texture, and flavor. Achieving these qualities naturally requires innovative solutions and attention to market-specific certification requirements.

Sourcing natural ingredients adds another layer of complexity. Consistent ingredient availability and costs must be factored in, alongside consumer demands for affordability and great taste. Natural ingredients also behave differently than conventional materials during large-scale production. This calls for adjustments in equipment, processes, and formulations to ensure efficient manufacturing.

RBS’s Science and Innovation Center: a hub for testing and development

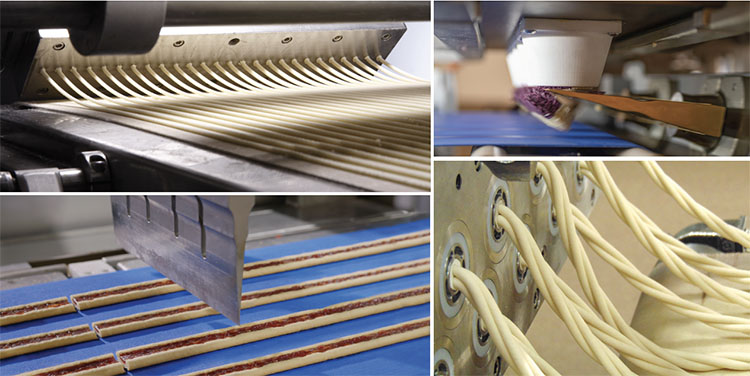

At the RBS Science and Innovation Center in Sinking Spring, Pennsylvania, manufacturers can test and refine their products using advanced processing technologies. Complete production lines for baked snacks, crackers, biscuits, cookies, as well as batch and continuous mixing systems are available to optimize clean-label snack production.

Cameron Johnston, Sr.,

Director of Innovation, RBS

Collaborative innovation

RBS specialists work with manufacturers from concept development to sensory testing of final products. “Clearly defining the goals for each ‘better-for-you’ concept is critical,” explains Cameron Johnston, Sr., Director of Innovation at RBS. “Whether it’s reducing sugar, sodium, or calories, or focusing on non-GMO and clean-label claims, each project is tailored to its target market.”

RBS observes growing demand for baked alternatives to fried snacks, supporting claims such as ‘Baked, not fried.‘ For instance, international markets often prioritize non-GMO ingredients, while school-focused products lean toward natural sweeteners like fruit-derived sugars to meet ‘no added sugar‘ claims.

The development process begins with an ideation phase, where project goals are clarified. From there, the plan takes shape, incorporating cost analysis, trial phases, and adjustments for production challenges. Ingredient selection and equipment compatibility are carefully evaluated to ensure smooth production.

“Selecting certain ingredients can introduce processing challenges, such as stickiness or fragility in dough. Each piece of process equipment has unique features that address these issues, so we pay careful attention to conveyance, dough handling, and contact surfaces to ensure smooth production. These considerations guide the equipment setup and adjustments needed for a successful trial,” the Center’s Innovation Director explains.

No two development projects are the same; those involving formulation testing, production cost analysis, and market strategy planning can take up to one year to complete. “Once a recipe is developed that performs well on the process equipment, meets nutritional claims, and aligns with marketing objectives, we often move to produce a sample batch for test panel evaluations. These evaluations are essential for gauging the product’s market potential and fine-tuning its appeal for a specific market,” Johnston highlights.

The testing process

Product development typically begins with small-scale trials to understand dough functionality. Once promising formulations are identified, they are tested and refined at the Science and Innovation Center. Adjustments to ingredients, water content, and processing parameters are made to optimize dough processability, flavor, and texture.

Trial runs monitor key metrics such as moisture levels, oven settings, and water activity. Real-time adjustments, enabled by touchscreen controls, allow for immediate fine-tuning during production trials.

“Instant control of speed, temperature, and airflow during trials is invaluable,” Johnston explains. “It lets us refine product characteristics on the spot.”

From pilot to full-scale production

Once a recipe is perfected, the transition to full-scale production begins. RBS uses the Scorpion® Profiling System to gather all of the baking parameters. This makes it easy to replicate pilot oven profiles to the production system at commissioning. This ensures consistency in product quality and production efficiency.

“The Scorpion® Oven Profiling System allows us to precisely match the pilot oven profile, ensuring a seamless transition to large-scale manufacturing,” says Johnston.

The journey to creating clean-label snacks is a team effort. With RBS’s expertise and state-of-the-art facilities, snack manufacturers can develop innovative products that meet today’s consumer demands while maintaining production efficiency and profitability.