Continuous baking: Go with the flow!

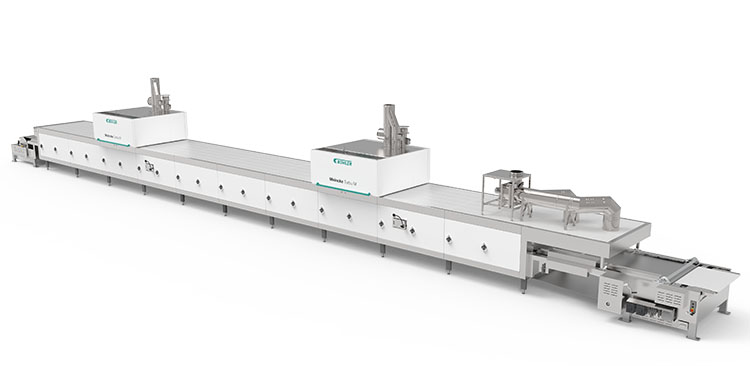

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Bühler sees an increase in requests for flexibility regarding energy sources, energy-saving solutions and alternative heating technologies. To these, sustainability commitments are added, which also translates into an increasing interest in carbon-neutral solutions.

“Bühler Group aims to save 50% water, 50% waste, and 50% energy in its customers’ value chains by 2025. This is how we are combating climate change with our innovations,” says Sonja Jeßberger.

Bühler announced the delivery of its first Prime Masa plant in India – the second Prime Masa plant worldwide – to PV Sons Corn Milling. The plant will consume 84% less water, 52% less energy compared to a traditional process.

Bühler partnered with Austrian start-up Selectum to provide a new, healthy and CO2-neutral snack. Selectum launched Paddies, crunchy wafer pillows with a creamy dip inside at the end of 2019.