VMI brings Phebus mixer to IBIE 2022

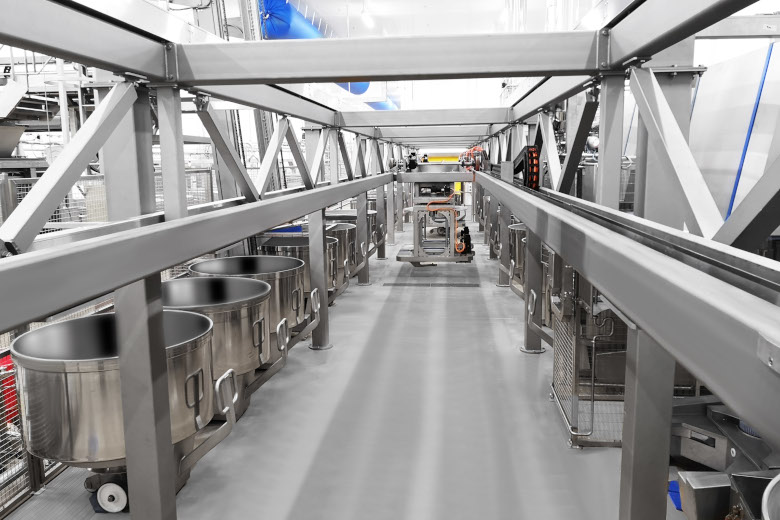

VMI shared in an interview the latest solutions that will be presented at its IBIE booth this year, in Las Vegas, from the latest planetary mixer, Phebus, to the Virtual Reality area.

VMI shared in an interview the latest solutions that will be presented at its IBIE booth this year, in Las Vegas, from the latest planetary mixer, Phebus, to the Virtual Reality area.

Continuous mixers allow for all parameters to be constantly monitored and saved digitally, including ingredient stream rates, dough temperature, mixing energy input, throughput, mixer shaft speed, coolant temperatures, starts and stops, ingredient refill status, ingredient totalizers, dough totalizers, and many others.

Automated continuous mixing delivers real-time process assessment and consistency round the clock.

In collaboration with major French players in the industrial bakery industry, the MEDEF International confederation has developed a 3D application called ‘Virtual Modern Bakery’.

The principle of the forked kneader came from the Mahot machine factory and provided mechanization of dough preparation. It has since proved itself in practice – and is still used today. The reason behind this is the technological proximity to French traditional, manual dough production.

VMI’s VERYMIX kneader is recommended for the continuous production of raw frozen, parbaked and/or pre-proofed and frozen doughs, including baguettes, ciabattas, pizzas, Viennese pastry, puff pastry and flour & water mixtures.

VMI has adapted and developed a “snacking” version of its vertical double tool mixer, the KNEADSTER, that fully meets product diversity requirements. With its specific tooling and its reverse rotation, all types of dough and meats/vegetables can be mixed.

The demand in global markets is changing. The focus is increasingly on snack products. This is also reflected in the program of the French dough production specialist VMI.