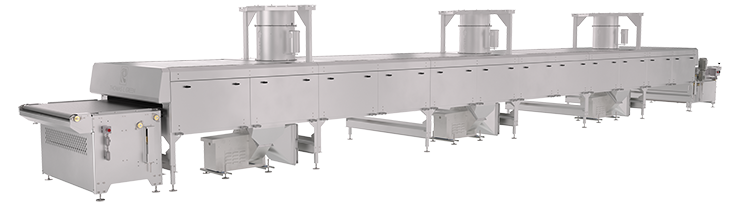

Gentle and fast product cooling

As crackers exit the oven, the cooling process is important to guarantee product quality and a long shelf life. A gentle cooling process will ensure the delicate product’s integrity until it is ready to be consumed.

As crackers exit the oven, the cooling process is important to guarantee product quality and a long shelf life. A gentle cooling process will ensure the delicate product’s integrity until it is ready to be consumed.

The principle of the forked kneader came from the Mahot machine factory and provided mechanization of dough preparation. It has since proved itself in practice – and is still used today. The reason behind this is the technological proximity to French traditional, manual dough production.

To consistently produce high-quality pizza, especially at high speeds in industrial environments, all types of equipment on the production line must contribute.

VMI’s VERYMIX kneader is recommended for the continuous production of raw frozen, parbaked and/or pre-proofed and frozen doughs, including baguettes, ciabattas, pizzas, Viennese pastry, puff pastry and flour & water mixtures.

In the industrial baking of any type of bread, and a multitude of other product ranges, tunnel ovens are the giants of large-volume, continuous baking, for which efficiency is a must.

In the industrial baking of any type of bread, and a multitude of other product ranges, tunnel ovens are the giants of large-volume, continuous baking, for which efficiency is a must.

VMI has adapted and developed a “snacking” version of its vertical double tool mixer, the KNEADSTER, that fully meets product diversity requirements. With its specific tooling and its reverse rotation, all types of dough and meats/vegetables can be mixed.

Future Foods was established as a start-up company in 2016 near Cairo, Egypt. Its main focus is the snack market in Egypt and the MENA (Middle East, Near Asia) region and it has a particular speciality called a “Fretzel”.

The Thomas L. Green brand of equipment from Reading Bakery Systems has been a partner to the biscuit, cookie and cracker industry for over 120 years.

New digital technology provides a better way to measure humidity in proofers, oven, dryers and cooling tunnels.

Reading Bakery Systems (RBS) is one of the world’s leading manufacturers of baking and process systems, especially in advanced high production cookie, cracker, biscuit, snack (baked chips, pretzels, expanded snacks, and bread snacks) and pet food systems.

Reading Bakery Systems, a member of the Markel Food Group, has re-engineered the MX Continuous Mixer. The model now ranks as the most versatile continuous mixer, and is suitable for a broad product spectrum and a wide diversity of doughs.