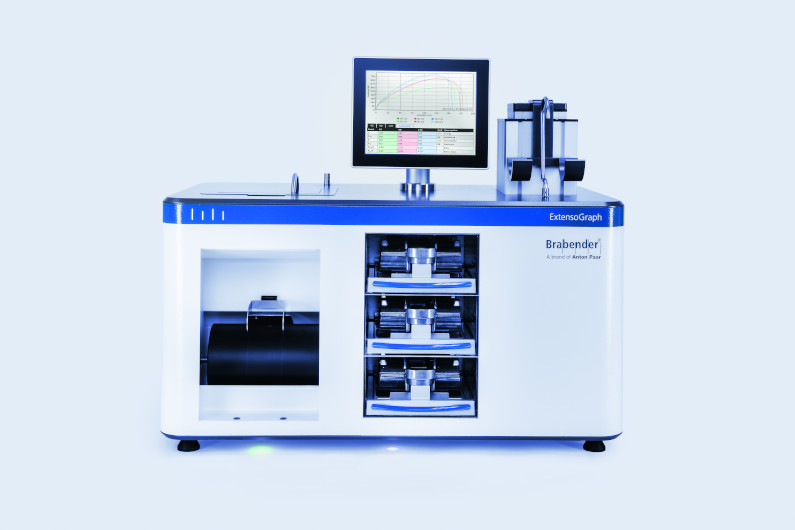

Anton Paar brings quality control solutions to iba ‘25

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

Batch mixing goes hand-in-hand with product diversity and varying quantities. It ensures the uniform distribution of the ingredients in the mix, with strict recipe control, yet great flexibility for diversity in formulations.

Two-stage batch mixing brings multiple advantages to industrial-scale baking. Two-stage batch mixing is especially suited to long-fermentation doughs, where structure and flavor are needed.

Spiral cooling and freezing systems have an unmatched capability to save space. For process consistency, they must also ensure even temperature distribution, and an uninterrupted conveying movement for minimum downtimes, while being easy to clean and maintain. Energy efficiency and scalability features are also important checkboxes for a reliable piece of equipment.

Artificial intelligence (AI) in manufacturing is no longer a fascinating idea – it is already here and accelerating quickly throughout many industries, especially in the baking industry. Several reasons are fueling this revolution.

Cookies speak the universal language of taking a moment for a delicious treat, anytime, anywhere. Technology provides different mixing methods to guarantee a perfect start.

As flatbreads grew to become a valued staple worldwide, technology has provided answers to all its production challenges, to match traditional handcrafting techniques.

IPCO will highlight opportunities for greater baking, cooling and conveying productivity at Gulfood Manufacturing. The Swedish company has a local sales and service network for the Middle East markets.

The 30th edition of südback lines up the best and latest solutions for bakery, confectionery, coffee, chocolate, logistics, training and more. International exhibitors are bringing the latest developments for the baking and confectionery industries to südback; several competitions will crown this year’s excellence in craftsmanship and innovation, and a full agenda of forums will be hosted for knowledge sharing.

Verhoeven Family of Companies launched its latest technology, its vacuum cooling and baking technology, remotely. However, equipment testing and adjusting the process to the specifics of the destination environment is key.

Product waste in industrial bakeries can arise from several factors, each contributing to the overall inefficiency of the production process. Understanding these causes is crucial for developing strategies to mitigate waste.

The 38th AIBI Congress brought the baking industry together this year for the moment’s most important topics, decision-making meetings and long-awaited reunions. The International Association of Plant Bakers organized this year’s event with the theme ‘21st Century Breeze over the Bakery’, and a picturesque location to match it: the city of Hamburg.