FRITSCH introduces third-generation ROLLFIX

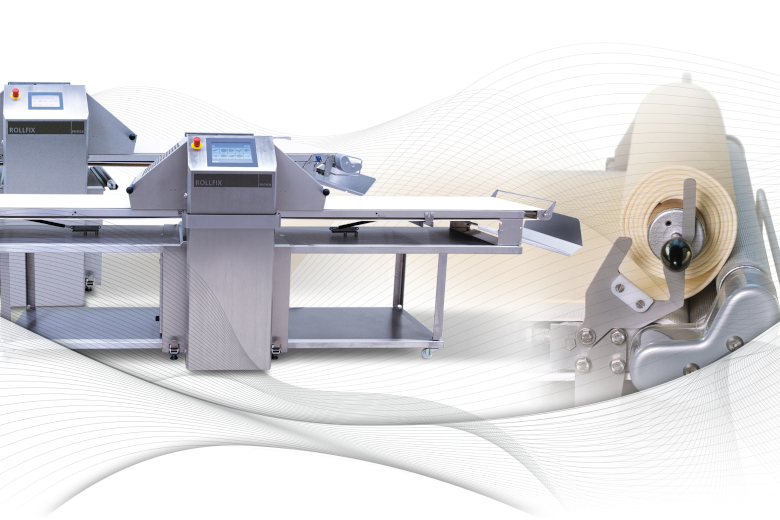

FRITSCH announced the relaunch of the centerpiece processing line of its portfolio, the ROLLFIX, now in its third generation.

FRITSCH announced the relaunch of the centerpiece processing line of its portfolio, the ROLLFIX, now in its third generation.

Replicating traditional methods of preparing buns, bagels and rolls on an industrial scale is a task with an extensive list of challenges, to achieve high-volume, consistent results. Flexibility and innovation joined in dedicated production lines help provide the answers for endless product variations.

A versatile piece of equipment that can be used for all processes requiring controlled temperatures is the spiral. For this technology, Ashworth developed the SmartSpiral® Monitoring System, an application that provides real-time monitoring of multiple spirals, even over different facilities.

Scoring is a process that requires skill and shows the baker’s experience when done manually. Alternatively, as labor is becoming harder to find (and then keep), robots can efficiently take over the task; they will never need to stop and will perform constantly over time.

Different types of products made with laminated dough have their own process requirements to achieve the desired characteristics. Flexible equipment is needed.

Mecatherm, French manufacturer of industrial ovens and production lines, has signed a partnership with American ABI Ltd, a specialist in bagel makeup equipment. Together they are planning to market an industrial bagel line. baking+biscuit international investigates further.

The bakery plant manufacturer FRITSCH has redesigned the LAMINATOR 300. The sheeting line is even more flexible and gentle in dough treatment.

For over twenty years, Rademaker’s Universal Make up line ranging from a laminator or bread line has made the production of a wide range of dough products possible to tickle the taste buds.

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

The line is recognized for its superb quality and hygienic design, its efficient operation, versatility, reliability and robustness.

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.

Minebea Intec, Hamburg, the German part of MinebeaMitsumi, a globally operating group (annual sales revenues EUR 7.3 billion), specializes in