IBIE 2022: Ashworth introduces new smart system

Ashworth will launch a new smart solution at IBIE this year, the Smart Oven monitoring system, joining the Smart Spiral in this range.

Ashworth will launch a new smart solution at IBIE this year, the Smart Oven monitoring system, joining the Smart Spiral in this range.

Regal Rexnord Corporation will display new releases from the Rexnord KleanTop® line at IBIE this year.

The consistency of perfectly formed dough depends entirely on the conditions during fermentation. DIOSNA develops pre-dough and dough fermentation systems that can ensure required parameters, with various degrees of automation.

American Pan’s facility in Alexandria, Romania, is the company’s main European operation headquarters for bakeware, with investments worth EUR 10 million planned over the next five years.

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Conveyor systems work under demanding conditions in bakeries. Maintaining them in top shape is the first step to efficiency in production; upgrades will then guarantee optimum performance in handling processes for truly competitive-level manufacturing.

Conveyor systems work under demanding conditions in bakeries. Maintaining them in top shape is the first step to efficiency in production; upgrades will then guarantee optimum performance in handling processes for truly competitive-level manufacturing.

It takes extensive experience to determine which belt works best with specific bakery products. Ashworth provides recommendations in terms of materials, design, and engineering. The choice will be the result of an extensive checklist and case-by-case analysis.

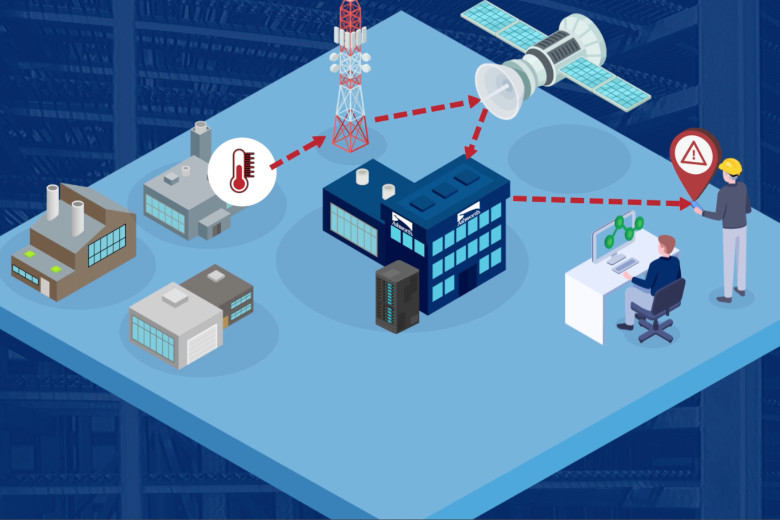

A versatile piece of equipment that can be used for all processes requiring controlled temperatures is the spiral. For this technology, Ashworth developed the SmartSpiral® Monitoring System, an application that provides real-time monitoring of multiple spirals, even over different facilities.

Maintaining a conveying system in its fully operational capacity is a prerequisite in increasing efficiency; upgrading it is then the next goal.

Several aspects determine what improvements a conveying system needs – starting with the process step it serves. Luis Patricio, Intralox Baking Account Manager, lists them.

Conveyor systems work under demanding conditions in bakeries. Maintaining them in top condition is the first step to efficiency in production.