Reformulating baked goods to have a lower sugar content must take into consideration the taste of the final products, as well as replicating sugar’s functional benefits. Predough processes are up to both tasks.

Sugar is a significant part of the carbohydrates listed in the nutritional value tables of baked goods. Brioche can be cited, as an example of a product available all over the world. Out of 100 g of product, approximately 40 g are carbohydrates – of which, around 10 g is sugar. Since sugar also has a technological benefit in addition to sweetening, predough processes can be used that pursue both goals.

If, by the activity of starch-splitting enzymes (amylases):

- a) cleavage products such as maltose and glucose are formed (reducing sugars), and

- b) the formation of which increases the aroma components that are produced during baking (Maillard reaction),

it is possible to reduce the total sugar in the recipe without affecting the taste of the product. For brioches, the sugar content can be reduced in this way by one-third.

Thermally-treated predoughs

Thermally-guided pre-doughs are made without using any microorganisms, by applying a certain temperature process to improve the water binding of dough components.

Temperature-controlled predoughs can be divided into:

- Cold soaker

- Brewed soaker

- Thermic processes

- Flour cooking, grain cooking

- AromaStück®

Thermic processes are analyzed below. When the raw materials containing starch are heated, the starch initially swells and finally gelatinizes above a specific temperature. This process opens up the starch molecule for the enzymes, which consequently work faster and with the highest possible yield. If a certain temperature is exceeded during heating (it varies depending on the enzyme), the respective enzyme is denatured, i.e. it stops working. The deactivation process does not happen suddenly.

Flour/grain cooking

Flour/grain cooking is achieved by heating a mixture of flour or whole grains with water, which causes the starch to swell and gelatinize. This water binding in the starch makes it possible to increase the bulk water used in the overall recipe by a few percentage points. There are multiple advantages to this, including an improved freshness of the resulting products and extended storage stability, even with refrigerated and particularly with frozen dough and baked goods. Raw materials that can be used with this method include flour, grist and grain.

If this process is stopped or only carried out for a short time, a certain proportion of the grain’s own active enzymes still remains in this thermal predough. In this way, a certain degree of saccharification can still take place after the gelatinization, because the enzymes can now reach the starch particularly well. Predough processes use this double effect:

- Effect a): water absorption, improves freshness,

- Effect b): sugar formation supports the reduction of sugar as an ingredient and forms a small proportion of additional aroma components after baking. But, attention should be paid to the risk of uncontrolled, non-comparable sugar formation occurring. Therefore, pure flour/grain cooking with targeted inactivation of the enzymes is the typical process. Water binding is the added benefit of this method. It can be used when looking into improving product freshness, without a major influence on its aroma.

The AromaStück® process

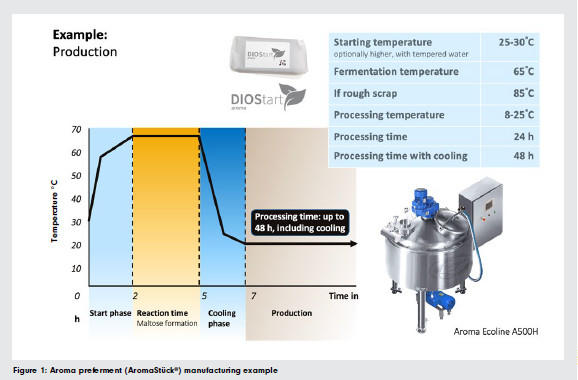

With the AromaStück® process, ground grain products are heated together with water and the DIOStart aroma starter. No baking agents are used. After a defined development time, a large number of aroma components and natural maltose are formed. This opens up the starch through swelling; but it also introduces a selected starter, which contains the grain’s own enzymes – an ideal target.

The AromaStück® changes the structure of the dough due to the proportion of saccharification. The dough becomes smoother and the structure of the dough becomes more homogeneous with regard to the distribution of the components. Within certain limits, there are effects that are known from emulsifiers.

This saccharification (in relation to the raw materials) is a complete process, meaning that the result of the saccharification is the same for each process batch, the optimum outcome for controlled results. It also supports salt reduction.

AromaStück® can be used with a range of raw materials, including flour, grist, and mixtures with seeds for thermal swelling. It is used for its natural sweetness and its role in reducing added sugar in the recipe.

The guided predough process, including the DIOSNA AromaStück®, comprises the preparation stage, when the raw materials are brought together (including the DIOStart, in the case of AromaStück®), which are then mixed and fermented/ heated to obtain the final predough. For an example of a working recipe, 100 kg of flour can be mixed in this process with 2 kg of DIOStart and around 150 kg of water.

Raw materials to use in thermally-guided predoughs:

Most suitable cereals and seeds:

- Flakes e.g., oat flakes

- Semolina and flour

- Wholemeal/shredded grain

- Whole grain

- Linseeds

Seeds with low soaking capacity:

- Sunflower seeds

- Pumpkin seeds

Flour:water ratios

When preparing thermic predoughs, different flour:water ratios are used, as the swelling and gelatinization depend on the type and accessibility of the starch, i.e. on the raw material. For the Grain Cooking process, flour:water ratios differ from 100:300 (Dough Yield 400) with wheat flour, to 100:600 (DY 700) – with oat flakes. For AromaStück®, flour:water ratios start at 100:150, using flour, and can go further depending on flour type, and if grains are added.

Enzymes

Some thermal predough processes are designed to also benefit from the effect of enzymes. In the case of grain cooking, in addition to a certain degree of sweetening achieved, enzymes that open the fiber could help to:

- improve dough handling,

- improve intake of minerals/trace elements from the grain.

For AromaStück®, enzymes can provide further support:

- to enhance sugar formation,

- to improve the intake of minerals/trace elements from the raw materials.

The DIOSNA aroma process

To develop the DIOSNA aroma process, experiments have been made with various natural ingredients that form sugar, in particular maltose, from the raw materials through natural biological activity. The characteristics of this process are the following:

- Rounded taste, obtained through the formation of different natural sugars from the starch

- Selective natural enzymatic reaction of fibers and proteins

- Distinct flavor profile for the entire range of baked goods

- Pleasant product browning using the natural sugar content

- Improved freshness, due to starch pre-gelatinization

- Reduction of malt products

- Neutralization of sour extremes

Read the full article in Baking+Biscuit International, issue 3 – 2023

Photos: DIOSNA