At iba, Baker Perkins will highlight its equipment solutions for dough dividing and molding, at the Coperion stand it shares with all the companies in the group, including Diosna, Bakon, Peerless and Shaffer, Unifiller, Shick Esteve and VMI.

Robert Francis, Head of Applications – Food Sales, Baker Perkins shared the company’s iba highlights and plans that meet current trends, in an interview:

BBI: What is the theme of your stand at iba 2025? What solutions will you highlight?

Robert Francis: Baker Perkins will be featured at the Coperion stand (12A.41 and 12A.51), which will bring together Coperion’s entire portfolio of technology brands. In this way, the Group will showcase all its integrated technologies and comprehensive production systems for the bakery, food, and pet food industries. Visitors can expect an immersive experience, exploring how these cutting-edge technologies seamlessly work together to meet diverse production needs.

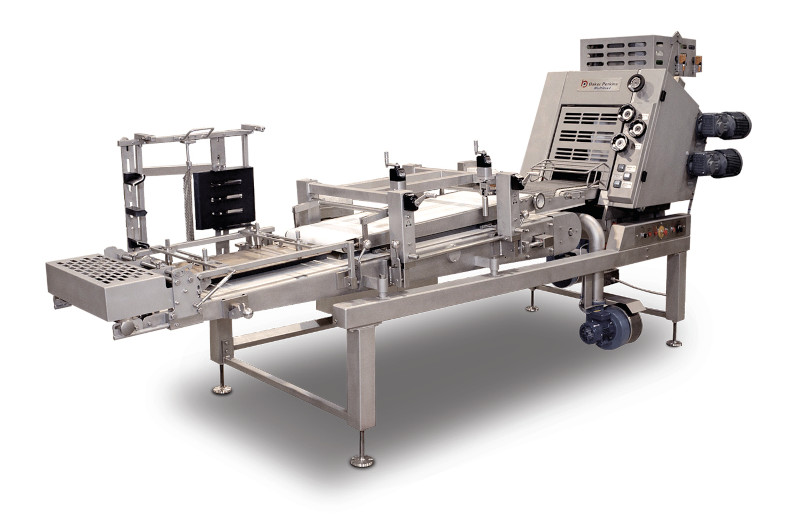

Baker Perkins will be exhibiting an updated Accurist2.1 Washdown Dough Divider and the Multitex4 Molder with a seeding attachment. Both machines are integral to producing pan/tin bread at high outputs – of up to 9,200 loaves per hour, while delivering high-quality products consistently, through a hygienic process. The units ensure weight control accuracy and gentle dough handling throughout the mixing and forming process, which enables them to achieve consistent high quality with lower production costs.

Ingredient costs are also reduced as less yeast and improvers are required to achieve these results. Because the dough is handled gently throughout the process, the cell structure developed in the mixer is preserved so the dough proves and bakes consistently, achieving the required volume, color and softness, for a lower price. Production costs are further reduced as the gentle handling eliminates the sticking and smearing that lead to jams: all machines in Baker Perkins’ range are designed for hygienic operation and easy cleaning, reducing maintenance costs, and lowering cross-contamination risks.

BBI: What new solutions or features will be introduced at the show?

Robert Francis: The Accurist2.1 Divider on display features an upgraded ram and knife arrangement as well as a full foam and rinse washdown function. The divider has been updated to make key components easier to clean. The knife can now be removed using an integrated support arm that allows the cleaning to be carried out outside of the divider. The knife is supported and swung away from the rear of the machine, enabling access to the ram, which can be cleaned on the spot. This way, components can be easily cleaned and inspected without manually removing them from the divider.

The Multitex4 Moulder will be displayed with its new seeding attachment, a module that can be fitted prior to coiling for the production of fully-enrobed seeded loaves. Rather than sprinkling seeds onto the loaf after forming, the molding process consolidates the seeds into the dough sheet as it is coiled, resulting in consistent coverage on each side of the loaf. As well as a visually improved loaf, this also reduces the waste inherent to the sprinkling process.

BBI: Are there any l events at the stand that visitors should schedule to attend?

Robert Francis: Coperion’s booth is designed to be a hub of activity and engagement. Visitors can look forward to live production line demonstrations, product showcases, and even the chance to taste goods from the bakery area. Baker Perkins will be featuring a laboratory-scale model of our high-speed Tweedy Mixer in the Coperion bakery area. We will be running demonstrations on this mixer throughout the show to illustrate the differences in dough produced with a vacuum-only mix, a pressure-only mix, and a combined pressure-vacuum mix, and how customers can use these varied mixing styles in their processes to improve their bread quality.

BBI: What are your main priorities in the baking market in 2025? What new/growing trends are you focusing on?

Robert Francis: As a technology brand of Coperion, we will begin identifying opportunities to integrate other Coperion technologies into our forming lines. Our forming units are well suited to work with mixers provided by VMI, DIOSNA, and Shaffer, as well as with Peerless’ dough feeders and conveyors. This allows us to bring comprehensive solutions to our customers.

The issue of hygiene, including eliminating cross-contamination risks, is a constant presence in all factory environments. So, Baker Perkins will continue to focus on hygiene improvements, washdown accessibility and innovations – such as the new ram and knife arrangement on the Accurist2.1 Divider.

Baker Perkins exhibits at the joint Coperion stand: Hall 12 – A 51.

Photo: Baker Perkins