At iba, Baker Perkins will highlight its equipment solutions for dough dividing and molding, at the Coperion stand it shares with all the companies in the group, including Diosna, Bakon, Peerless and Shaffer, Unifiller, Shick Esteve and VMI.

Technology alone can only ever be part of a solution – it also requires the knowledge to use it efficiently and profitably. This is precisely why Rademaker has installed the RTC at its headquarters.

Last year, Raymond Nogael was promoted to President of MECATHERM. He shared the company’s strategy for development and sustainability, along with his perspective on the industry after 10 years with MECATHERM.

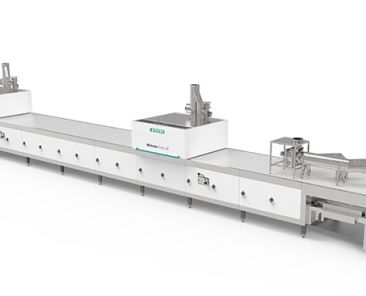

Continuous baking in industrial bakeries answers production needs for volumes and consistency over time. However, it comes with several challenges that need to be managed to ensure efficiency, product quality and profitability.

Batch mixing goes hand-in-hand with product diversity and varying quantities. It ensures the uniform distribution of the ingredients in the mix, with strict recipe control, yet great flexibility for diversity in formulations.

Two-stage batch mixing brings multiple advantages to industrial-scale baking. Two-stage batch mixing is especially suited to long-fermentation doughs, where structure and flavor are needed.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Artezen developed a technology concept for dividing doughs that are challenging to process, which ensures excellent end products.