Flatbreads contribute significantly to the sustainability of food systems. They can be made from various cereals, pseudocereals, or pulses, promoting the use of local produce from marginal lands. Their short baking times, which can even eliminate the need for an oven, reduce energy consumption. Additionally, their ability to wrap around food or serve as utensils lessens the need for tableware and saves water. Their compactness during transportation reduces energy impact, and when baked dry, they have a prolonged shelf life, minimizing waste.

By Dimitris Argyriou, food scientist, Grainar Managing Director

Among its myriad forms, ‘flat’ breads stand out due to their distinctive thinness, ranging from mere millimeters to a few centimeters in thickness. These ancient breads, originating from varied parts of the world, have found their way from the Fertile Crescent to regions including North Africa, Southern Europe, the Middle East, the Anatolian peninsula, the Indian subcontinent, the Caucasian region, Xinjiang, and the Arabian Peninsula, with connections extending to the Horn of Africa. In the Americas, flatbreads are prevalent too, especially in Central and South America, and also among Native American communities.

Despite their ancient origins, flatbreads remain popular today. They can be produced traditionally or through modern, fully automated industrial processes. They are versatile, often used as a base for street foods like döner kebab, shawarma, gyro, Italian pizza, focaccia, and French fougasse, which are enriched with various ingredients. The demand for ready-to-eat foods has led to a significant increase in the consumption of flatbreads, with the global market expected to grow substantially.

However, there is still potential for improvement in both technical and nutritional aspects. The fast, high-temperature baking process can cause quality issues, such as uneven cooking and the formation of harmful compounds like benzopyrenes and polycyclic aromatic hydrocarbons (PAHs). New baking systems, such as indirect heating with rotary baking trays, and Bake Off Technology (BOT) for domestic baking, show promise. Moreover, flatbreads offer opportunities for nutritional enhancement through fortification with various animal or plant-based ingredients, boosting protein and micronutrient content.

Fact: The global flatbread market size was valued at USD 38.8 billion in 2018, then increased to USD 41.17 billion in 2019, and is estimated to reach USD 62.8 billion by 2026, at a compound annual growth rate of 6.2% (Allied Market Research, 2021).

Flatbreads are generally made from flattened dough of flour, salt, water, and yeast. The main production steps are kneading of ingredients, leavening (optional), shaping and baking.

Flatbreads categorization

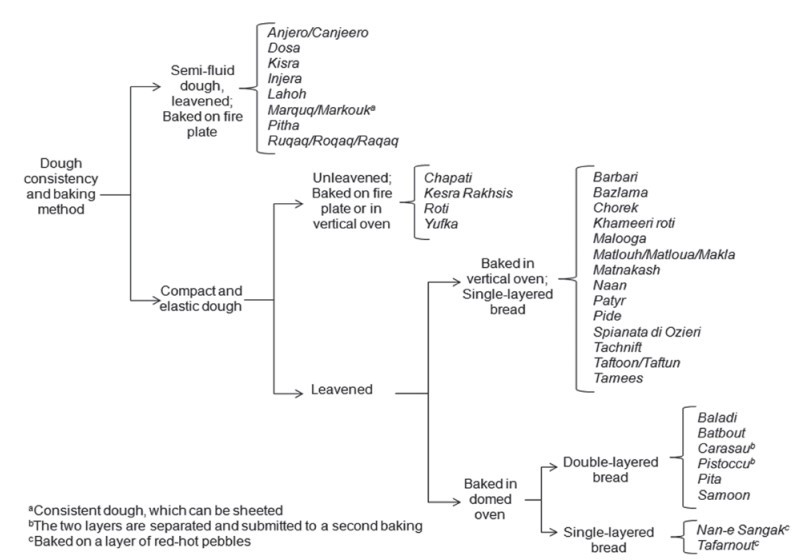

Owing to their unique composition and preparation techniques (Figure 1), various classifications have been proposed to categorize flatbreads. Broadly, flatbreads can be divided into two main types: single-layered and double-layered.

Figure 1: Types of flatbreads. Source: A. Pasqualone, Tecnica Molitoria International, Yearly issue 2018

Single-layered flatbreads are typically categorized into two subgroups: leavened and unleavened. Leavened flatbreads are created from semi-fluid batters or doughs. An example of a flatbread made from a semi-fluid batter is the Ethiopian injera, often made from gluten-free cereals such as rice, sorghum, teff, maize, or black beans. These batters are usually fermented twice before being pan-baked. The fermentation process, involving lactic organisms and yeast, imbues these breads with prebiotic and probiotic benefits. Alternatively, leavened flatbreads from doughs are allowed to rise twice before being baked at high temperatures in an oven.

Unleavened single-layered flatbreads, like roti, tortilla, and paratha, typically measure 12–25 cm in diameter and have a thickness of 1.3–3.0 mm. They are traditionally cooked on a clay griddle like naan, iron pan like roti, or fried with oil like paratha or deep-fried like poories. These frying methods impart unique organoleptic properties, identified by specific compounds like 𝛿-decalactone -oily/peach, 2-acetyl-1-pyrroline – roasty/popcorn-like. However, due to their high-fat content, these fried flatbreads are generally less recommended for consumption. Industrially, flatbreads are produced using methods such as hot-press, die-cut, and hand-stretch.

Main ingredients used

The quality of flatbread is significantly influenced by two primary factors: the genetics of the wheat and its growing conditions, and the quality and quantity of raw materials used in conjunction with the breadmaking methods. High-quality flatbread is characterized by its ease of digestion, a delightful and fine aroma, and a texture that neither crumbles too easily nor stales rapidly.

- Flour – For flatbreads like lavas, taftoon, barbari and sangak, the preferred flour is usually soft white wheat flour with higher extraction levels. It is generally observed that for several types of flatbread, flour with an extraction rate of 80% or less is ideal. Extensive research has been conducted to identify the most suitable type of soft wheat flour for flatbread production. For instance, soft white wheat has been found to be optimal for making baladi bread. In the context of Arabic bread, which is a double-layered flatbread, the finest quality is achieved using hard wheat flour with a protein content of 10-12% and over 6% of damaged starch.

Mixing durum wheat flour with Indian wheat flour has been shown to enhance the quality of Chapati. Durum wheat flour, known for its higher starch damage during the grinding process, results in a softer crumb in flat bread due to increased water absorption and starch gelatinization.

The water absorption rates of flours used in flatbread production vary widely. While flour for pan bread typically has an optimum water absorption of 60-65%, the range for flatbread flour can be between 38% and 85%.

- Yeast – Flatbreads can be either leavened, using bakers’ yeast or sourdough, or unleavened. Bakers’ yeast contributes to the aroma, matures the dough through the fermentation of fermentable carbohydrates, and aids in dough rise through CO2 Sourdough, a mixture of flour, salt, water, and a piece of dough from previous baking, involves a complex interaction of lactic acid bacteria and yeasts. Sourdough fermentation can improve the texture and palatability of various bread types, stabilize or increase levels of bioactive compounds, reduce starch bioavailability (resulting in low glycemic index products), and enhance mineral bioavailability.

Key production steps

- Mixing and kneading: The process begins by combining wheat flour with ingredients like salt and water, and often bakers’ yeast or sourdough, to create a dough. This step is crucial for blending all elements uniformly.

- Resting: Unlike fermented breads, many flatbreads are made from unleavened dough that doesn’t undergo fermentation. Therefore, the dough is typically allowed to rest for 30 to 60 minutes. This resting period is essential for the dough to absorb water, which aids in the development of starch and proteins. However, too long a rest can negatively impact the quality of the flatbread.

- Fermentation: For flatbreads requiring fermentation, the dough is leavened with bakers’ yeast or sourdough. This process produces carbon dioxide and ethanol, causing the dough to rise. Fermented doughs often have enhanced flavor, texture, and longer shelf life.

- Dividing, rounding, sheeting: The dough is divided into portions and rounded to improve gas retention and facilitate shaping. The thickness of the dough sheet, which ranges from 2 to 10 mm, is critical and varies based on the type of bread. This stage also involves removing gas from the dough structure.

- Baking: Flatbreads are baked at high temperatures (typically between 350-550°C) in specialized ovens (Figure 2) or on hot plates (Figure 3). The baking time and method vary depending on the type of flat bread. For example, some are baked quickly on a hot plate, while others are baked in an oven for a longer period. The high temperature and baking duration are key factors in achieving the desired crust characteristics.

Shelf life enhancement in flatbreads

Flatbreads, valued for their taste, aroma, and texture, tend to stale quickly due to lean formulations. This staling, marked by firmness and altered organoleptic qualities, diminishes consumer acceptance. With lifestyle changes, urbanization, and a shift towards convenience foods, there’s a growing demand for fresh flatbreads.

Large-scale production, mechanization, and packaging that preserves the bread’s sensory characteristics are required. New technologies and processing conditions have been developed to combat staling and extend shelf life. This includes altering recipe components and modifying process conditions to provide fresh bread at any time.

Emulsifiers like Glycerol Monostearate (GMS) and Sodium Stearoyl Lactate (SSL) have been effective in reducing staling, particularly in Chapatis stored at ambient and refrigerated temperatures. They help by forming complexes with starch, maintaining moisture content and reducing starch solubilization. Surfactants can form complexes with amylose and amylopectin, contributing to bread softening. This interaction helps in preserving the freshness of the bread. Hydrocolloids such as guar gum enhance the extensibility of both fresh and stored flatbreads, contributing to longer shelf life. Alpha-amylases of the maltogeMIC type A are used to slow down the staling rate of flatbreads. These, along with water, act as plasticizers, preventing the rigidity of starch and gluten chains, thus extending shelf life. Various wrapping materials have also been explored for packaging flatbreads, showing potential in keeping them fresh during storage and distribution.

Nutritional values

The nutritive value of flatbread is fundamentally linked to the chemical composition of the flour and additional ingredients used in its preparation. Incorporating optional ingredients not only improves the processing quality but often enhances the nutritional value, leading to the creation of specialty and novelty breads. The main ingredient in flat breads, wheat flour, significantly influences their nutritional quality. The use of wheat flour with different extraction rates in flatbread production markedly affects its nutritional profile. Lower extraction rate flours reduce the content of minerals and other phytochemicals in flat breads, whereas higher extraction rates result in increased levels of protein, fiber, sugars, lipids, and minerals, along with a reduction in starch content. Flatbreads made from whole wheat flour are particularly noted for their higher levels of nutrients and minerals.

Conclusion

In conclusion, flatbreads, encompassing varieties like naan, pita, and focaccia, are today a remarkable blend of tradition and modernity. As symbols of cultural heritage, they remain integral to our diets even amidst evolving culinary trends. Flatbreads have changed to fit modern tastes and health needs. They are a big part of street food culture and are now being made healthier to meet what people want today. This shows how flatbreads have grown from being an ancient basic food to something that brings together old traditions and new ways of eating.

Selected references:

1. AlliedAnalytics. (2021). Flatbread market size 2021 | business status, industry trends and forecast to 2026 | allied market research – EIN Presswire https://www.einnews.com/ pr_news/557304899/flatbread-market-size-2021-business-status-industry-trends-and -forecast-to-2026-allied-market-research

2. AlliedMarketResearch. (2021). Flatbread market size and demand | industry research report, 2026 https://www.alliedmarketresearch.com/flatbread-market

3. Boukid, F. Flatbread-a canvas for innovation: A review. Appl. Food Res. 2022, 2, 100071

4. Mintel. (2020). A year of innovation in bread & bread products, 2020 – Mintel https://clients. mintel.com/report/a-year-of-innovation-in-bread-bread-products-2020?fromSearch = %3Ffreetext%3Dbread%2520types

5. Mintel. (2021). Mintel global new product database https://www.gnpd.com/sinatra/search_ results/?search_id = 3tMdwh5e47&page = 0

6. Pasqualone, A. Traditional flat breads spread from the Fertile Crescent: Production process and history of baking systems. J. Ethn. Foods 2018, 5, 10–19

7. Qarooni, J. Flat Bread Technology; Chapman and Hall: New York, NY, USA, 1996; p. 208

Read the full article in Baking+Biscuit International, issue 1 – 2024.