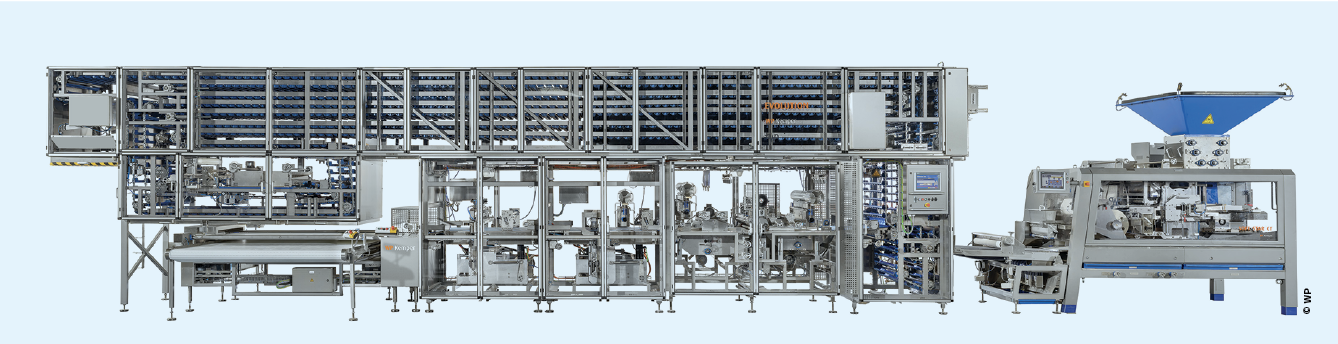

A system for industrial bread roll production

WP ROLL is the name of the system consisting of the EVOLUTION bread roll machine and the SOFT STAR CT high-performance dough divider from WP. Production is gentle on the dough, precise and hygienic.

WP ROLL is the name of the system consisting of the EVOLUTION bread roll machine and the SOFT STAR CT high-performance dough divider from WP. Production is gentle on the dough, precise and hygienic.

The L’Artisane baguette line is destined to change the world of industrially produced baguettes. As a result of Benier’s new system, the baked products are designed to achieve high quality without final proofing.

FactoryXperts, baking industry consultants from Switzerland, uphold this motto in the sustainability sense as well. According to the advisers, although

SALTEK is an international leader in the production of Pita Bread Automatic Production Lines. Saltek’s facility is located in the industrial zone of Mazraat Yachouh/ Metn in Lebanon.

The Verhoeven Bakery Equipment Family in the Netherlands – BVT, NEWCAP and VACUUM & BAKEPACK are parts of this Family – which offers turnkey solutions, e.g. in the lamination technology area.

The F-Series proofer concept from Sveba Dahlen belongs to a new generation of proofers jointly developed with bakers from all over the world. Smart functions are given high priority to simplify and streamline everyday workflows at the bakery.

At the südback trade fair, Werner & Pfleiderer showed their new Puncho hole punch module for bread rolls. It now allows the manufacture of products with holes, e.g. bagels or donuts.

The packing solution from Rego Herlitzius: a BS 45 band slicer combined with a Vertec 30 promises to be a powerful bread slicing and packing combination for industrial bakeries.

The bakery machine constructor Gostol-Gopan is growing steadily. Further expansion is taking place especially in the “Complete bakery solutions” area.

Metering and depositing – machines in the Dutch manufacturer BAKON’s BD series can also undertake these tasks. The BD3 Multi-Depositor is designed as a bench-top equipment for smaller bakery businesses, bigger machines such as the BD9 variant allow the metering and depositing process to be increasingly automated.

The GEA Comas DV3 Multi-Depositor system allows simultaneous extrusion and deposition of two doughs and an additional medium-viscosity filling input.

The VEMAG Slice Depositor made by the US-American company Reiser can automatically top sandwich slices with chicken salad, peanut butter,