Continuous baking: Go with the flow!

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Providing excellent-tasting products is a must, but the eating experience is only one of the goals for successful snacks. The challenge lies in balancing health benefits, clean-label compliance, and manufacturing efficiency – all while meeting consumer expectations.

An entire fleet of iconic crackers built its consumer base on their open, flaky texture, which is produced by layering the dough. Reading Bakery Systems designed a new, 90-degree technology concept for the laminators manufacturing this dough.

Savimex has been thriving on disruptions; those that came its way and those that it is boldly innovating. The cracker and pretzel producer has made a name for itself in Europe and beyond, with its own brands including Savi, and private-label offerings.

The conversation around increasing manufacturing sustainability will unavoidably start with analyzing ovens, for any baking operation. Visible results are a necessity.

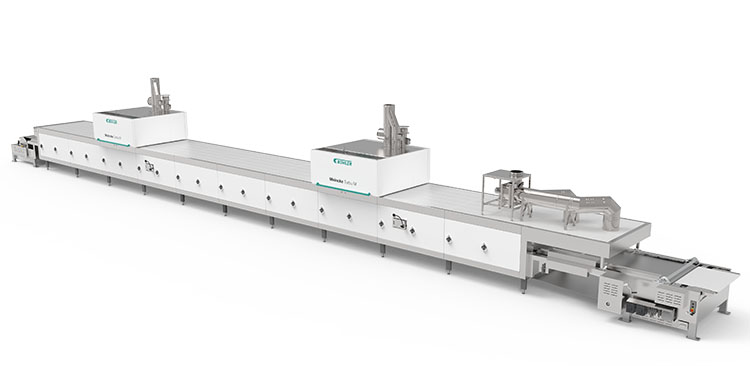

Reading Bakery Systems unveiled the new Thomas L. Green Emithermic XE Oven, a superior replacement for traditional Direct Gas Fired (DGF) ovens. This new oven reduces energy and emissions, and simplifies cleaning and maintenance.

While the salty snack market continues to grow, it is feeling some effects from tightened budgets. Mintel research shows those who report their financial situations as struggling/in trouble are most likely (34%) to have decreased year-over-year salty snack consumption.

As crackers exit the oven, the cooling process is important to guarantee product quality and a long shelf life. A gentle cooling process will ensure the delicate product’s integrity until it is ready to be consumed.