Under the current circumstances, it has never been more important to look into ways to increase efficiency in bakeries, starting with their centerpiece: the tunnel oven. Mindful technology innovation is here to provide benefits in efficiency and sustainability. Baking a vast range of high-quality products is only the start of what cutting-edge tunnel ovens can do.

Oven preferences are different on each side of the ocean: while European bakeries favor product flexibility, high-capacity oven systems are preferred in the US. Electrically heated ovens are also more in demand in Europe. However, all markets and technology developers share one common priority for oven improvements: sustainability.

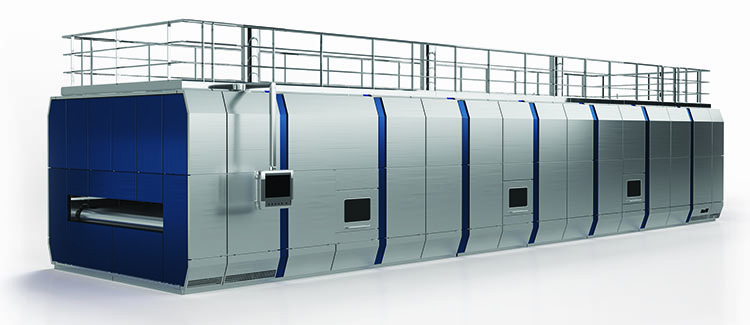

© Mecatherm

Flexibility for industrial volumes: MECATHERM

MECATHERM provides many choices to adapt tunnel ovens to specific needs, including certain cleaning options, different types of conveyors, energy sources, or settings to adjust baking parameters according to the product range.

For the all-important product quality trend, MECATHERM developed the modular M-TA tunnel oven. This award winning oven offers multiple heat transfer modes, such as convection or radiant heat, or a combination of both, in each of its independent heating zones, to the required product specifications. “It is a flexible oven choice for a line that excels at baking vastly different products, from crusty, pastry to patisserie products,” explains Marie Laisne, Product Marketing Manager at MECATHERM. “By providing just the right quantity of energy in a minimum baking time to reach the product quality criteria, this oven offers an optimal energy consumption solution,” she recommends. The kind of product influences the type of energy transfer that should be used for the best results. The baking phase is also considered for this choice, from development to stabilization and coloration.

For industrial production, MECATHERM’s main focus is performance optimization. In this regard, the ease of access for the operators is key to enabling easier maintenance and cleaning operations. For instance, for baking products with the highest sanitation standards (e.g., protein-based products), the FDAN tunnel oven is fully accessible and can be easily cleaned with high-pressure water.

MECATHERM is also making advances with innovative digital solutions to help with current market challenges: “The new M-CARE digital solution is an intuitive interface that enables industrial bakers to detect drifts in equipment, anticipate potential breakdowns, and support operators and maintenance teams to ease the first level of maintenance,” Laisne explains. Most of MECATHERM’s new ovens are ‘M-Care ready’.

Through automatic settings, baking parameters can be precisely controlled via the HMI settings including baking times, temperatures, heat transfer modes and their intensity, as well as steam injection and extraction.

Sustainability and consistency

Regarding the increasing concern for sustainable solutions, MECATHERM recommends using as much as possible convection as a heat transfer mode, which both shortens the baking time and reduces the fumes’ temperature (when using gas burners). In addition, “The oven temperature regulation should be monitored with precision to avoid unnecessary overheating,” she recommends. For instance, lowering the temperature of the fumes from 350°C to 150°C lowers energy loss through fumes by 40%.

A new energy-saving feature of MECATHERM ovens manages the damper opening settings, to minimize the amount of fresh air that enters the oven during regular baking operations. “A digital solution assesses the exact quantity of extracted flow as well as the quantity that is effectively extracted. This data allows the baker to adjust the extraction settings close to the required balance point and optimize the energy consumption,” the French specialist adds. Additionally, MECATHERM is currently working on project development that will measure and precisely adjust the humidity rate inside the baking chamber, she reveals.

To ensure process consistency between batches, recipes are pre-registered in the HMI. To finetune the process, MECATHERM runs numerous airflow simulations in the oven’s design phase. The company’s R&D team has developed its own simulation tool to help analyze the simulations, which is used for more than five years in every development process.

Last but not least, all Mecatherm tunnel ovens are compatible with an electrical power supply without any changes in baking performance, while also reducing the ovens’ CO2 emissions.

The next steps in oven tech

A new solution is currently under development, to help provide adjustments for increased productivity: a data analysis tool for the information collected from a single piece of equipment, or an entire line. “Ultimately, it will provide a dashboard to monitor the equipment/line performance,” anticipates Laisne.

Long-term developments at MECATHERM will aim to support industrial bakeries in their road to sustainability, with ovens with improved energy management and, consequently, lower CO2 emissions. Green baking is completed by baking precision: “A development area we are researching is, for instance, precise humidity management that plays a key role in the final product quality,” she shared.

Sustainability is well on its way to being profitable, for the environment, for the baking process efficiency, and for the business, with plenty of interesting opportunities regarding tunnel ovens.

The article is part of an extended feature, which was originally published in [BBI 4 – 2022]. Read the full article in the magazine: