Consumers are bound to reach for snacks more and more in the following years. Snacks are diverse and enticing additions to any eating occasion, whether they stand in for an entire meal, or are seen as a treat, a catering option for events, or a movie-night companion. Manufacturers stand to gain by keeping up the pace with innovations in this category. Extrusion provides particularly interesting opportunities.

It’s not just an increasing number of occasions that is boosting snacking; even ‘no occasion at all’ can call for a snack. For example, Euromonitor lists boredom among the core reasons why consumers reach for snacks in 2023, a habit boosted by their availability.

To meet this growing appetite, manufacturers of extruded snacks and pretzels have the opportunity to increase their product variety and SKUs. Flexible pretzel and snack systems that can process a variety of snacks can best support an expanding portfolio. Reading Bakery Systems (RBS) provides such technology: “For any type of bread or pretzel snack, the RBS Low Pressure Extruder (LPE) can produce a variety of shapes and types of products. From traditional pretzel twists and flat ‘chips’ to sticks, rods, braided ropes and even filled nuggets, it can handle all ranges and unique variations,” the RBS specialists highlight. Recipe-driven oven settings can create customized baking profiles for a wide range of products.

The LPE has recently been upgraded for improved functionality, ergonomics, and sanitary design of the hopper structure. The latest hoppers are made of single-piece blue plastic with no seams or weld points, eliminating any nooks where dough could get lodged and risk harboring any pathogens. Additionally, the new hoppers are now easily removed from the machine without the need for tools. “A single operator can easily disassemble the hopper structure in minutes and carry each piece away for cleaning without the need for a crane or any heavy-duty equipment,” the specialist explains.

“From traditional pretzel twists and flat ‘chips’ to sticks, rods, braided ropes and even filled nuggets, the Low Pressure Extruder can handle all ranges and unique variations.”

Reading Bakery Systems specialists

The LPE system forms the dough in a two-step process: at first, the dough must be cut into 4-6 kg chunks (10-12 lb) to feed into its hoppers. “The RBS DoughBot system automatically takes dough from the mixer and cuts it into these chunks using our loafmaker,” RBS says. Then, a shuttle system distributes the dough to the LPE hoppers. In the second step, the dough then works its way into the extrusion chamber of the LPE, where two augers force the dough toward the compression head and die. “This force is what develops the pressure in the chamber. For bread snacks and pretzels, you typically do not want pressures to exceed 100 psi,” the specialist recommends. This pressure is determined by the spinning speed of the augers. These settings can be automatically adjusted using controls that modify the size of the dough chunk and the pressure applied.

The dough is then cut into its final shape as it exits the extruder die. The bandcutter cuts the dough to the user’s desired thickness. The related settings can also be automatically adjusted based on the recipe needed for each product, keeping in mind that thinner pieces require faster cutting. For sticks and nuggets, the dough is extruded and then cut after the proofer by a guillotine cutter or an ultrasonic guillotine cutter, depending on the fragility or stickiness of the product.

One machine, all of the snacks

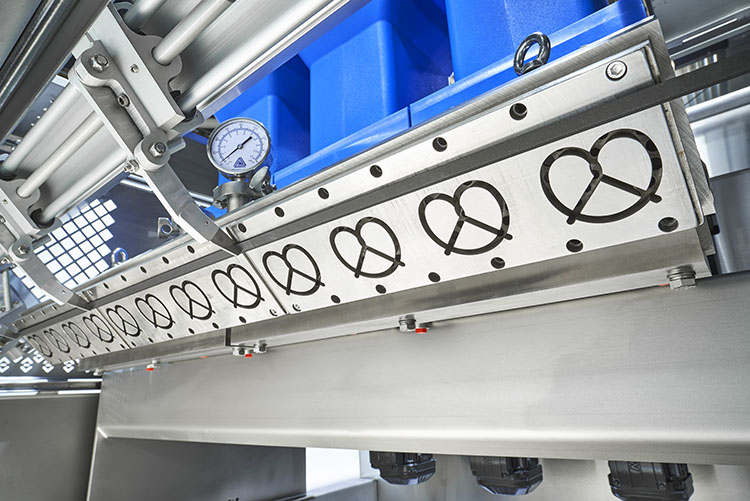

To increase the product variety of shapes on the LPE, interchangeable compression heads and dies are used. The ability to support fast changeovers is key to the flexibility of this extruder. “Switching between a standard pretzel shape and a round flat piece simply requires changing these plates and takes just a few minutes. Recipes can also be saved into the control system to automatically adjust dough pressure, auger and band cutter speed to create pieces of dough of consistent weights every time there is a changeover”, RBS explains.

There are numerous dies available to choose from with shapes ranging from sticks, rods, braided sticks to filled and co-extruded products. But these are only a few of the options, as a whole world of other new shapes can be custom-designed from ideas brought to the RBS team of engineers and extrusion experts. Snack manufacturers can also visit the Science & Innovation Center to develop the new products together with RBS. A test die can be designed to create the shape desired, and then modified if the shape is not working exactly as intended.

Almost any conceivable shape can be created, with only a few limitations, such as shapes with extended ‘arms’, for instance, that would make the resulting piece prone to breakage in the process or the package. “The more compact the shape, the stronger it is. Our experts can design shapes with appropriate feed plates that help meter the dough through the die at adequate speed and pressure so the dough is able to knit back together in time to form a cohesive shape. A customer can present a concept to our experts and together we can work with them to make the shape into a snack, or adjust it to improve strength and integrity to withstand the entire process,” RBS explains.

Once a new die has been created, new products can be introduced into production with the LPE system by changing over the system to the new die, and then running its recipe from the control settings. “If the dough has any allergens or requires cleaning from a previous allergen, there would be time needed to clean the line prior to running the new product,” the specialist observes.

The high-capacity pretzel lines developed by RBS can run volumes ranging from 500 to 1,000 kg per hour. Volumes will vary according to the size of the product and the weight of each piece and are ultimately determined by the size of the oven. The longer and wider the oven, the more volume the line is capable of.