An enticing range of breads is carefully crafted to answer the consumer’s unwavering love for a slice of wholesomeness, whether it’s an artisan-style bread or roll, ciabatta, focaccia, or a baguette. It’s their time to shine, in all creative interpretations, with the technology ready to reliably back up production.

A relaxed dough makes the best bread! For artisan breads of European inspiration (and beyond), dough need not only to be stress-free during the process, but also well-hydrated, in many cases.

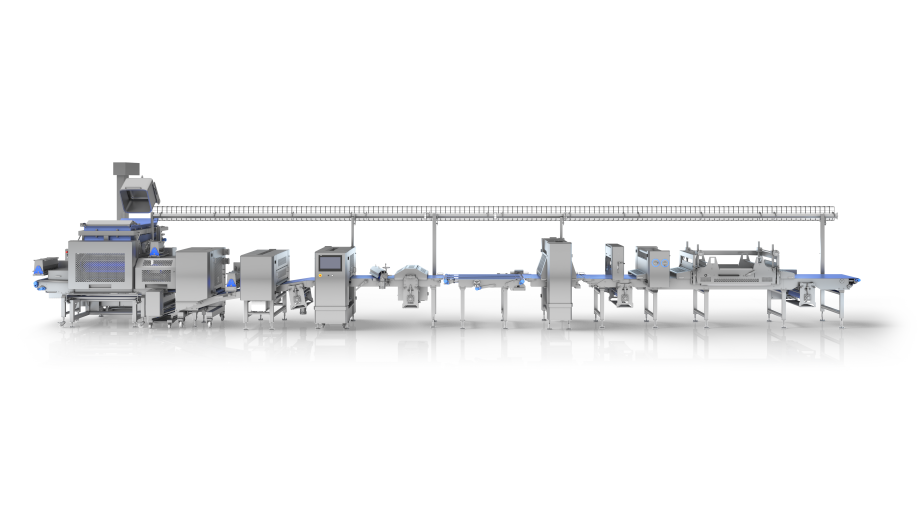

A new IMPRESSA for bread, by FRITSCH

Making its debut on the best stage for a first impression, at iba, the new, compact IMPRESSA bread line developed by FRITSCH for industrial production manages to save 20% of the floor space – about 5 m. This was accomplished, in part, by new sheeting technology incorporated in the revised Soft Dough Sheeter (SDS) and the new Soft Dough Roller (SDR). A sensor in the SDS monitors the dough level in the hopper; when it falls below a certain threshold, new dough is brought in on another conveyor belt. “This allows for greater precision and more even weight distribution when producing the dough sheet,” the specialists point out. Next, the SDR gently rolls out the dough, a uniform dough sheet with very well-defined edges, obtained with no separating agents and without applying shearing forces to it. In this way, dough scrap is reduced to a minimum throughout the process. Moreover, thanks to its fold-up conveyor belts, the SDS flours the dough sheet on all sides, thereby eliminating the need to use any oil at all when rolling the dough out.

The line’s open design allows modules to be easily swapped as well as ample access for cleaning. This is because the design is now flatter, making many components easily accessible from the side. Another design revision was made to the handling concept of the longitudinal cutter: the roller can now be accessed by opening the hood. If the hood is raised above a certain point, the cutting roller is released and can be changed quickly. A counterpressure roller ensures the appropriate power transfer during cutting.

The design of individual components also favors hygiene: it features smooth surfaces, watertight covers on threaded connections, and rounded corners where no dirt can accumulate. Some components, such as the conveyor belt table of the SDS and the SDR are now mobile and can be cleaned in the washing area. In addition, “Fold-up knife edges, like those on the feed table of the calibrating head for example, ensure good accessibility for cleaning even in relatively tight spaces,” FRITSCH specialists illustrate. The drives on the line are also new – on the so-called ‘omega drives’, the belt can be completely relaxed in a matter of seconds, which makes cleaning under belts a quick and easy process as well.

The new Dough Twisting Unit used for twisted bread rolls achieves an output of 60 cycles/min and row.

The new IMPRESSA bread also comes with FRITSCH Smart Services, a family of digital solutions such as the Smart Production Insights (SPI) and the newly developed ‘Watchdog’ for drive monitoring. The smart tools help monitor the key performance data of the line in real time. The aim is to achieve complete production transparency, in addition to insights supporting predictive maintenance. The SPI service was established to give production and shift managers real-time insights into the most important performance data of the line on a clear dashboard. FRITSCH explains: “Even minor malfunctions that occur intermittently during production are recorded by the SPI and reported on. This data can be inspected to determine what is causing the faults, and the appropriate measures that can be taken to prevent unplanned line stoppages.”

The ‘Watchdog’ digital service monitors the motor power and the temperature of every drive on the line. “As soon as an algorithmically calculated value deviates by a specified amount from the set target value, a warning is sent to a defined group of people, so they can react accordingly before the drive unit becomes damaged or even destroyed,” adds FRITSCH.

The article is part of an in-depth feature published in Baking+Biscuit International, issue 1 – 2024.

Photos: FRITSCH