From the beloved classics to the unexpected modern creations, the finest viennoiserie and puff pastries enjoy unwavering commitment from consumers. Along with the enthusiasm around all things patisserie, expectations are also rising.

The love of pastry and viennoiserie products is unbothered by cost-of-living worries; on the contrary, the appreciation for fine bakery is growing, as it provides an important moment of indulgence and affordable luxury, when other experiences have had to leave shopping lists. The global pastry market, in which Europe ranks first, is estimated to be around EUR 61 billion this year, and projections show it could reach EUR 72.27 billion in five years – a CAGR rate of 3.44% . Consumers increasingly expect unique flavors, premium ingredients (including healthier options and sustainable options), innovative recipes and craftsmanship, regardless of the type of shopping channel at hand.

Specialized equipment that allows close control of the entire manufacturing process is a considerable advantage in industrial bakeries. How to mass-produce delicate creations that look, feel and taste on par with hand-crafted offerings? Dedicated lines are involved. Looking at the endless product possibilities, a flexible line is needed, to answer various production demands, while also ensuring accuracy with no exception.

French specialties made with French technology

Bringing French flair to viennoiserie and French technology into production, Mecatherm offers a concept line that can help manufacture many types of viennoiserie (and other products such as morning buns): the Mecacroissant production line, with equipment covering all processes from proofing to cooling and freezing. The company develops solutions that reliably produce croissants matching the French product quality standard.

The line ensures smooth handling of the product throughout its processing cycle, to guarantee its iconic shape is preserved. But, Mecatherm also tailors this line to meet the product characteristics of any international product range in this segment. Besides the traditional flaky French croissant, made from laminated Danish dough, a very popular trend in Eastern Europe is the brioche dough croissant, for example. Both of them can also be topped or filled, which brings additional challenges in industrial production.

“The software plays out different production scenarios on the 3D model of the manufacturer’s production line to help them achieve the best

availability rate and the lowest changeover times.”

Mecatherm specialists

The Mecacroissant line can be adapted to run as a multiproduct line, as the machines in its setup are suitable for different types of products. The M-TA tunnel oven is designed to support extended product ranges with precision; the same goes for the M-UB proofer, which is also suitable for a wide range of products, including the most delicate ones, with any type of filling. Mecacroissant lines can produce up to 35,000 baked regular croissants per hour.

François Retailleau (Production Lines Manager), Fabrice Bourion (Equipment Product Manager) and Xavier Gotti (Ovens Product Manager) share Mecatherm’s perspective on processing pastry and viennoiserie products and how to utilize the Mecacroissant to fully make use of all its benefits. This production line is adapted to each project and to the products, processes, constraints and production rates of each manufacturing site, the specialists explain. The process stages may remain unchanged for all types of viennoiserie; however, perfecting each specific product is in the details, with parameters to match their size and unique profiles.

For example, proofing times can vary: they are usually longer for long shelf-life products – which can take up to eight hours – compared with frozen products, which only require two hours for proofing. This process step poses challenges to preserving product characteristics; the proofing temperature must not be too high, so that it doesn’t alter the fat, and the proofing time must be adapted to the desired shelf life. Mecatherm credits the M-UB proofer and cooler for smooth product handling, which is essential to preserving the unique shape of delicate viennoiserie such as croissants.

In a different scenario, if various types of products need to be produced on indented or flat trays, the equipment will be similar in both cases; but, the operators will have to change the trays between batches. “To make this operation fully automated, we can add a storage gantry to the production line, which can manage several sets of trays,” the specialists add.

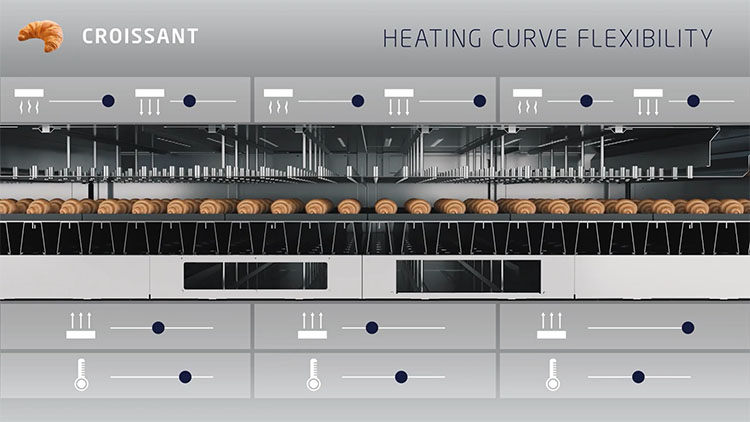

The Mecacroissant can also be adapted according to the process required by the final product. “For a product with a long shelf-life or premium quality products, it is important to be able to precisely adjust the baking curve and the heat transfer mode; the M-TA oven is particularly adaptable for that, for example. On the other hand, to optimize industrial performance, footprint and energy efficiency, the vertical oven is a very good alternative,” Mecatherm’s team illustrates. The oven’s baking curve can be adjusted by fine-tuning the heating mode (radiation or convection):

+ To obtain the expected crust coloration: color contrast or even coloration

+ To customize the texture and volume: from crispy to flaky, with a more or less open crumb

+ To manage the moisture content (which impacts the product shelf-life).

Perfecting viennoiserie production

The production of viennoiserie, and, in particular, layered pastries filled with cheese or meat, is a considerable endeavor in terms of hygiene, as these ingredients come with strict requirements. “To meet these challenges, the M-TA oven can be equipped with an access window for easy cleaning and a stainless steel belt to reduce clogging. With these options, it becomes an excellent solution for products that require a high level of hygiene, as it provides very precise and flexible baking in a full wash-down oven. Its hygienic design makes it especially suitable for the production of sensitive products,” Mecatherm’s specialists explain.

Flexibility is also a major challenge to be addressed when manufacturing fine bakery, and is particularly reflected in the baking process, respectively the oven technology behind it. “To meet this challenge, we recommend the M-TA oven, which is very flexible thanks to its very precise and customizable baking curve. It allows manufacturers to produce even the most demanding clean-label products, formulations that have no additives and are made with natural ingredients, as well as free-from and better-for-you product ranges (such as gluten-free, or wholemeal recipes) – both important trends in the viennoiserie market,” Mecatherm’s team underlines. The M-TA is also the best oven choice from Mecatherm’s range when producing a diverse range of products or when a precise adjustment of the baking curve is needed, as it features independent baking zones. “The adjustable parameters make it possible to have either convection or radiation at the top or bottom,” Mecatherm’s specialists highlight. The hygrometry can also be adjusted on this oven, which is particularly beneficial for products with a long shelf life.

If the product requires convection baking only, then the vertical oven solution is the recommended technology – a compact solution designed to optimize industrial performance.

“In order to better manage the perfect hygrometry level in the ovens, both types of ovens are compatible with the Hygro Control System, which will be launched soon. This innovative solution will allow the automatic adjustment of the hygrometry inside each oven module independently,” Mecatherm’s team explains.

New developments for energy savings

Both of Mecatherm’s oven technologies come with a unique profile, a list of benefits that includes the potential for energy savings. The vertical oven significantly limits energy losses through its walls, conveyors and fumes, thanks to its compact design. Moreover, using convection means that they can bake at lower temperatures, while benefiting from an even heat transfer around the product, again translating into energy (and time) savings.

Mecatherm is also developing new solutions to optimize energy consumption, starting with the Hygro Control system, which will offer automatic hygrometry management, reducing CO2 emissions and energy losses due to fumes. The Energy Recovery System is another soon-to-be-launched solution, which will make it possible to save additional energy throughout the line by recovering the energy produced by the baking vapor and converting it into pre-heated dry air. The energy recovered can be used to preheat the oven with dry air, but it can also be used for other pieces of equipment along the line, including the proofer, the steam boiler, or even beyond the line, such as the building’s hot water circuit. Moreover, “Most of Mecatherm’s ovens will soon be compatible with an electrical heating source,” the specialists note, which will not only save resources, but will also limit C02 emissions.

The fill level of the oven and the production rate are also considered, so that the oven is heated accordingly: the parameters will automatically adapt, thanks to modular burners. “Our oven convection technology limits the flash heat effect thanks to the convection baking mode and a high rate of air renewal in the baking chamber,” the oven specialists explain.

Accurate and sustainable baking

Perfecting the baking curve for each product guarantees the best results with optimum resource allocation. Both of these priorities can be fulfilled along the entire production line, for increased sustainability in production, on one condition: that all processes are under complete control. Here, smart features play a decisive role.

For example, the pastry line can integrate the EYE-Q quality control system, developed by Mecatherm’s sister company, ABI LTD. The system is driven by AI to perform real-time quality control for every single product on the line – not just samples selected at random every 100 items or every 15 minutes. “The EYE-Q classifies the products and provides a trend analysis to improve line performance,” the specialists explain. The smart inspection system can be positioned at any critical point on the line, such as depositing, where it can ensure that no double dough pieces are entering production and that each piece is correctly positioned at the center of the conveyor. Another possible placement is at the exit from the proofer, to inspect that the level of the dough rise is correct.

The greatest enemy of productivity is, undoubtedly, sudden production stops. The company can integrate a buffer on the Mecacroissant line to save production when such stops occur: it will store the products in the oven so the batch is not lost.

And this is not the only waste management mechanism that is utilized (on all Mecatherm solutions) to limit product loss. Most of the machines ensure smooth product handling, to avoid bringing any shocks to it (such as the M-UB handling system), and are designed to minimize necessary manipulations/transitions, to further avoid damage. Overall, “The precision of the equipment guarantees production homogeneity, limiting product losses,” the team adds.

Correct planning also contributes to baking more sustainably. The M-plan simulation tool can be used to optimize production scheduling. Its batch follow-up feature also allows for changeover management optimization and minimizing waste: “The software plays out different production scenarios on the 3D model of the manufacturer’s production line to help them achieve the best availability rate and the lowest changeover times,” they explain.

The setup of the Mecacroissant line supports product innovation, as it can easily introduce new creations into production. To optimize settings and formulations, new products can be tested at Mecatherm’s Demo Center in Barembach, with support from the company’s team of master bakers.