Whether sliced bread rolls, crispy rolls, yeast pastries or rye bread – the König plant manufacturer supplies the appropriate technical equipment for the production of a wide variety of rolls and breads.

General and detailed view of the bread roll plant. All conveyor belts can be relaxed without tools for easy cleaning. The hourly output of the Combiline plus is up to 11,880 dough pieces in a 6-row operation

“We see a big demand for cleaning reworked materials and the ‘Easy Clean’ design fits the bill as an easy to operate system. Offering a high degree of versatility for different types of bread rolls, the Combiline plus EC bakery machines are easier to clean, maintain and service.

We will therefore be continuing to extend the ‘Easy Clean’ series, which does what its name suggests to our commercial and industrial range,” explains König Managing Director, Wolfgang Staufer.

König sees similar trends worldwide, such as the demand for more cost-efficient machines and processes through easier cleanability and maintainability to reduce non-productive time. A system should also offer flexibility and future security so that new products can be easily adjusted to when market requirements change. In addition, there is another trend: “In general, we see a development towards quality products. We are again limiting ourselves to the essentials: Baking with high-quality ingredients and giving bread the time, it needs, for example with long-time dough methods,” Wolfgang Staufer explains.

Modular bread roll line

Easy cleaning, short changeover times and the prevention of contamination are becoming increasingly important for bakeries of all sizes. For this reason, König has completely redesigned the Combiline plus, already a benchmark for high product quality, to meet the demand and to minimize downtime. The ‘Easy Clean’ concept allows for reduced cleaning and downtime, while the innovative frame design ensures optimized hygiene and accessibility.

The system has a maximum output of 11,880 pieces per hour in 6-row operation. Bakeries can use this line to produce sliced rolls, ribbed rolls, Kaiser rolls, hamburgers, hot dogs, rose rolls etc.

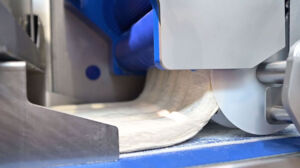

The ‘Easy Clean’ design with a new type of frame construction ensures optimized hygiene and accessibility. According to the company, the slanted surfaces at a 45° angle prevent flour and dough residues being deposited. All conveyor belts can be relaxed without tools for easy cleaning. The plant offers generous floor clearance of at least 300mm and adjustable feet are not positioned directly next to each other. In the plant design, screws were predominantly omitted, and welded constructions were mainly used to prevent dirt from depositing. The stamping station, forming station etc. are in open design for easy access; the forming tools are easy to remove and can be stored cleanly and are protected on their own storage trolley. The machine is also equipped with UVC tubes for sterilization of the hangers. This serves to disinfect the surfaces and inhibits the formation of mould.

The dough band line is designed as a modular system. It is easy to clean, as the most important parts can be easily dismantled and the system is easily accessible

Dough band machine in ‘Easy Clean’ design

The Artisan SFM EC will process both fine-pored doughs and coarse-pored doughs with high water content gently and accurately, and can process a wide range of bread roll varieties from corn snacks to crispy fresh to Mediterranean ciabatta. The Artisan SFM dough band machine in the ‘Easy Clean’ design is made as a modular system. It is easy to clean because the most important parts can be easily dismantled and nothing sticks to the surfaces due to the sloping surfaces and generous legroom. Since the system can be quickly adapted to different products, it is suitable for craft businesses.

The plant has a dough throughput of 400 to 1,200 kg per hour for rolls and 400 to 1,500 kg per hour for bread. For square rolls this corresponds to a capacity of 16,200 pieces/hour with 6-row operation and 45 strokes/min.

Another special feature of the system is that the special shaping of the dough band without residual dough means that the dough quantity is 100% used, as opposed to other systems which have losses of more than 15% due to residual dough, according to König. Forming tools such as inserts of the rounding station, cutting or punching tools can be easily changed without tools. Flour and sprinkling containers can also be changed easily by means of a slide-in unit.

The forming tools can be easily changed without tools. Flour and sprinkling containers are also easily exchangeable by insertion