Tyrolean family business MPREIS is taking technology innovation personally. Its bakery in Innsbruck, Therese Mölk, is a state-of-the-art facility that continuously adds the latest improvements to optimize efficiency in production.

Therese Mölk Bakery’s century-old history can be understood in the diversity and the quality of the products it offers. Its breads and pastries are made with premium, local ingredients that are free of preservatives. Over 80 varieties are sold, ranges including organic,

vegan, and lactose-free products. The specialties made here include appetizing options such as sourdough buns, ancient grains breads, rye sourdough breads, carrot pumpkin seed bread, and organic butter kamut bread, to name just a few.

Björn Buschhorn, sales manager, Rademaker; Catalina Mihu; Nancy den Dunnen, Marketing and Communication, Rademaker; Mathias Mölk, Manager, Therese Mölk Bakery, co-owner of MPREIS

he company runs 260 stores in Austria, South Tyrol, and Italy, with a total staff of 6,000 – out of which, the bakery employs 180 people. Sustainability and regionality are the utmost important values to MPREIS, for the food it sells and the ingredients it uses. It is also why they chose to create a distinct identity for each of the locations; each store is unique and sustainable. What started as a bakery founded by Therese Mölk in 1925 is now a 12,500-sqm, IFS-certified, state-of-the-art facility that produces around 12,000 tons of bread per year. MPREIS rebuilt its facility in 2011 to better fit the operations of Tyrol’s biggest bakery, bringing the latest technology on board to support this rich tradition and the company’s growth. The newest solution to be installed in the facility in Innsbruck is a bread and bun sheeting line from Rademaker, which went into production just a few months ago. Its role is to support an ambitious capacity increase of 250% (with existing product ranges) and raise the level of automation in all manufacturing sequences. The dough for the company’s ‘Alpenspitz’ organic baguette, for example, was manually rolled, a process this Rademaker line is now automating. Similarly, tray-loading was automated for half of the production before adding the line, and now the system automatically does this 100% of the time.

”This bread line is one of the most versatile versions of the Rademaker bread lines on the market, in what product variety is concerned, as well in its design.“

Björn Buschhorn, sales manager, Rademaker

The project of bringing a new line on the production floor, however, started quite some time ago, before the pandemic. The market research began as early as 2014. The company saw the momentum that single-serve, smaller breads were enjoying, a trend that fits right in with its focus on product variety, and included the organic segment, in which MPREIS is a market leader. Once the assessment was made, a detailed list of requirements followed, which a new line would need to meet: it should support scaling up production, be able to produce a wide variety of breads, including clean-label products with no additives and long resting times; and be able to manufacture products with an artisan look and feel. Such a line would also need to have and easily support a high hygiene level, support fast changeovers, and minimize dough waste, detailed Mathias Mölk, Manager, Therese Mölk Bakery, co-owner of MPREIS.

It goes without saying, flexibility and automation topped the list. It was the flexibility of this line, which could take on the product variety the bakery needed, that made it the best fit for the job, the way it combines handcrafting techniques with high-volume, automated capacities, Mölk added. Efficiency is also in the spirit of the entire design of the modern facility, a must for all new equipment.

© Rademaker

Four-in-one

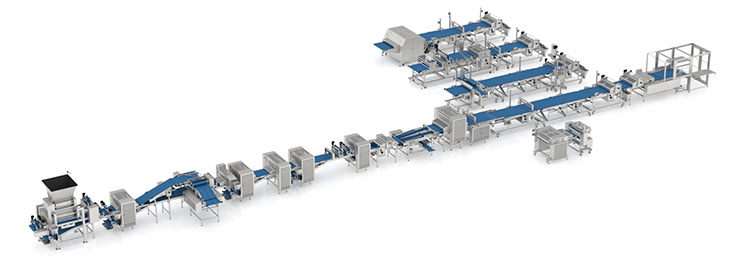

The Rademaker bread line was designed around a very similar checklist, which made it such a good fit for the bakery’s needs (and plans). It is one of the most versatile versions of the Rademaker bread lines on the market, in what product variety is concerned, as well in its design, said Björn Buschhorn, sales manager, Rademaker. It can be used to produce a wide range of breads, with soft dough, strongly hydrated dough, pre-fermented dough, dough made with organic ingredients, and firm dough. This particular modular bread line has a working width from 600mm up to 1,000mm, with a pre-sheeting system and inline laminating. The Rademaker bread line produces five product groups/shapes:

+ Cut products, for instance heart-shaped buns;

+ Long molded products like baquettes;

+ Rounded products. e.g., 90-gram bun 650-gram bread;

+ Coiled products such as salzstangen or kornstangen;

+ Flatbread, for example fladenbrot.

After or during shaping, toppings can be added to the products such as seeds, coarse (pumpkin seeds), medium (sunflower seeds) and fine (sesame seeds) particles. Sprinkle mixes can also be used. Sprinkling can be done from above and below. At the end of the line, peelboards, as well as baking trays, can be used.

© f2m (Mihu)

The dough is brought onto the line and is being formed into a continuous sheet by the pre-sheeting system. The dough is gently reduced with a quick reducer and then travels on the conveyor belt to the next step, lamination, where 4 to 6 dough layers are created. Laminating the dough provides a better proofing stability and creates more volume of the baked goods. For even more product variety, this step can be skipped, and the dough sheet can be rolled out right away, the so-called non-laminated dough. The dough is then formed via a second quick reductor, a cross-roller and two gauging stations. The crossroller is used to avoid dough tension/stress as it runs left and right across the dough sheet that comes out of the reduction stations. It also ensures that the dough is here at the desired thickness and width.

After the reduction steps, the dough sheet is cut lengthwise, trimmed at the sides, spread and cut to length with the guillotine, and then, depending on the shape of the product, formed. At the end of the line, the products are automatically deposited on trays or proofing boards.

The line includes a new dough recycling system Rademaker developed. It ensures the rework dough, which results from cutting the sheet into its final size, is directly transferred back into the pre-sheeter to maintain the high quality of the dough. Benefits are three-fold: minimizing waste, saving labor and costs, which can be significant especially when using premium, organic ingredients.

The bakery switches in between various mobile modules to have each alternating on the line. The line was producing Mantovane breads when we visited; dough sheets formed, sized, oiled, cut, rolled, and positioned on trays. At the start of the shift, the module is swapped before production starts. A product changeover varies from 10 minutes (for cut products) up to 20 minutes (for rounded products). Depending on the type of product and required tooling you need one ore two bakers. The modules are built on wheels for ease of handling and easier changeovers at the request of the customers. The modules can be modified, supplemented and extended at any time, Rademaker explains.

A team of two is assigned to the line’s operating shift: a baker who mixes the dough and a baker who monitors and supervises the production line. Few manual operations are needed, filling the flour sifter among them. Each shift makes two types of products, for efficiency.

The line is suitable for wet and dry cleaning. It is designed with round edges, tubes, ducts and angled surfaces to make cleaning easier.

Never a waste

Bread waste is virtually eliminated with the bakery’s newest project, the distillery, which MPREIS kindly included in our tour of the facilities. It uses stale bread, which is fermented with sugar for one week: 100kg of bread crumbs result in 12.5l of high-percentage alcohol. A container of white bread is distilled in about 1.5h, while for dark bread, the process takes up to 3h, depending on the properties of the alcohol, the flavor (of the bread and/or the desired flavor of the resulting drink). At the beginning of the pandemic, hand sanitizer was also made here for in-house use, which helped maintain hygiene when it wasn’t easily available elsewhere.