Technology is optimized to meet the clear trend for flexible equipment that can support changes in production and a diverse range of breads, respectively. New developments also aim at bridging the gap between artisan and industrial production, in terms of product quality and production volumes, so that the production lines can grow together with the operation.

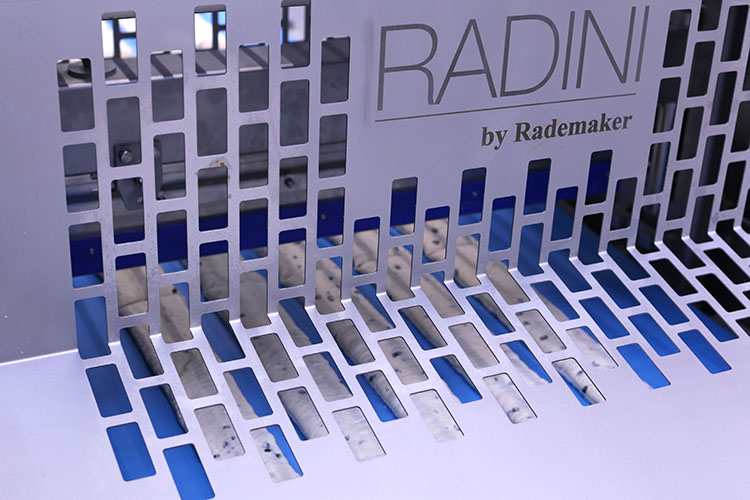

iba set the stage for numerous new concepts in all specialty fields. Bread remains at the very core of the industry, with several new developments that serve improved manufacturing processes encompassing all possible needs. The Radini bread line was one of the new technologies making its official debut this October, in Munich. It joins the namesake range of equipment that specializes in laminating, pastries, croissants and donuts under the ‘artisanal meets automation’ theme.

Bread with Radini

Rademaker designed the Radini bread line as a modular concept that can process from 250 up to 1,200 kg of dough per hour. The modularity allows for changing configurations and growth together with the business. The line can be configured for partially- or fully-automated setups, for products such as seeded baguettes.

“Manual labor can be added, for shaping products from the automatically produced dough sheet with operations such as twisting, braiding, or rounding. Decorations can also be made by hand, by adding almond paste filling to make Christmas bread, for instance, or by adding raisins on top of the product. The flexibility of fully automated combined with manual processes contributes to the flexibility of the baker’s product range,” explains Arjen Eberwijn, Manager, Business Development, Radini.

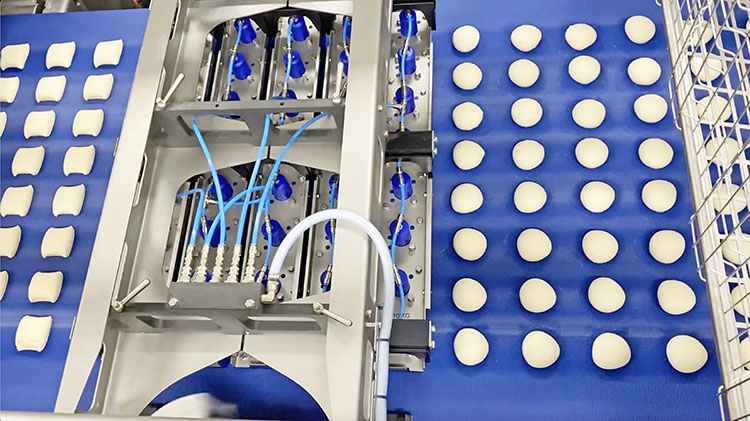

To determine the right levels of automation that fit the bakers‘ production goals, they can start with manual shaping and rounding, Eberwijn recommends: “When the baker decides that a higher level of automation or increased output is needed, modules can be added. In this case, a molding unit or rounder can be easily added to an existing line.” Another automation opportunity is the step of placing dough products on trays. A tray loader can be added to the line for automated tray loading even at a later stage and can (gradually) be expanded with a rack (un)loader. “Such options are possible because the software is modular, and so are the mechanical units. The Radini platform is prepared to add units over time,” he adds.

The minimum configuration of the Radini bread line consists of a Dynamic Pre Sheeter, combined with a traveling guillotine. To this, every unit in Radini’s portfolio can be easily added. Everything following the guillotine is plug and play, designed to be interchangeable and customizable to specific process requirements. “Developments in this segment do not stop with the launch: meanwhile we have developed a molding conveyor, and next year we will start the development of a bread rounding module,” Eberwijn shares. Its pre-sheeting system allows the Radini bread line to handle various types of dough, from firm toast bread to pre-proofed ciabatta. All kinds of multigrain doughs and doughs with inclusions of fruits, seeds, nuts, or olives can be made into bread. “A consistent, low-stress, high-quality dough structure is achieved by gentle dough handling,” the specialist highlights.

To optimize production efficiency, dough sheets of different widths can be processed. For a changeover, in this case, the final sheeting rollers can be easily exchanged. In addition, the cutting knives can be changed, and the spreading conveyor is adjustable to produce the needed number of lanes. For a different product shape or length, the cutting tool in the guillotine can be switched.

This line prioritizes space limitations, with the Dynamic Pre Sheeter at its heart, which has a footprint that only spans 3.5m and produces dough sheets ranging from 15 to 40mm thick. A relatively thin sheet of dough can already be achieved by this unit, which means that fewer sheeting components are needed further along the line, so that its overall layout can be more compact while producing the desired dough characteristics – to answer one of the questions Rademaker frequently received from iba visitors at the launch. “While the dough batch is processed in a continuous dough sheet, gas is retained,” Eberwijn adds.

Another frequently asked question is regarding Radini’s ability to eliminate rework dough. “For example, by not having to take rework dough into account, it does not have to be recalculated in the recipe of the next production run and returned in the dough batch. When seeds are added for decoration, there is no costly waste,” the specialist illustrates. Producing without rework is made possible by enclosing the dough sheet, among other things.

And more bread on the line: the Rademaker bread line

When higher volumes are the priority, the Rademaker bread line can be the next step, with a capacity of up to 9,000 kg per hour and the option for dedicated, custommade solutions, to also provide a high degree of flexibility.

The latest upgrades to this line were also among the novelties at iba this year, where the latest version of the make-up section was presented. Improvements on this high-volume line include increased efficiency and functionality. The enhanced line is also more user-friendly, has improved hygiene features and its footprint has been reduced. “A highlight is our state-of-the-art weighing conveyor. The system combines a high-quality weighing system with innovative software algorithms, enabling bakeries to precisely control the weights of any dough products,” Olaf Stok, Product Manager, Rademaker, explains. The weighing conveyor is placed after the spreading conveyor and before the cutting unit. The system helps regulate the line’s software, upstream and downstream. This functionality enables bakeries to precisely control the weight of end products.

“Our new bread rounder has improved process control, excellent process visibility and a new conveyor belt design.”

Olaf Stok, Product Manager Rademaker

Product shaping modules have been upgraded: “Our new bread rounder has improved process visibility, a new conveyor belt design and lighter weight of changeover parts,” Stok adds. The rounder is an evolution of the successful previous generation and features a programmable excentre working in a 20mm – 50mm range, to optimize the rounding movement for an optimized end product quality.

A wide range of possible configurations increases the flexibility of the Rademaker bread line. Starting with the sheeting technology, a household specialty of the Dutch company, a diverse range of doughs can be handled with this bread line, with either long or short pre-proofing requirements. The first step is creating a continuous sheet of dough, for which there is a choice of two pre-sheeters: the Double Chunking Stress Free System (DSS) and the Dynamic Pre Sheeter (DPS). “Processing pre proofed doughs up to TA185, meaning a water percentage up to 85%, both pre-sheeters use the same technological principles to work on their own range of dough processing capacity. The pre-proofed doughs are sheeted using Quick Reducers (multi-roller), Cross Rollers and gauging stations. Depending on the required dough sheet thickness, line configurations can vary.

Then, there are various options to form products from the dough sheet: “We have multiple units such as guillotines (for cut products), a molding table (for rolled products) and our new version of the bread rounder (for rounded products), which has just been introduced,” Stok says. The guillotine itself can be equipped with different product-related changeover parts to produce cut products in unique designs, while the versatile molding table can be used to optimize the shaping of artisan baguettes, for example. The bread rounder can handle short and long pre-proofed doughs, as well as rye-based doughs ranging from 40 to 950 grams in dough weight.

Rademaker’s Radilinq product group offers solutions for further automation in dough handling through the baking facility. “Our innovative and flexible production lines allow our customers to stay ahead of their customer (future) needs. Through smart, modular designed units, fast product changeovers are made possible. It will yield maximum results in terms of product quality and return on investment.” Stok underlines.

As market requirements are changing in time, existing lines can be modified by either adding new modules or features, so that the line is ready for the next decade.

Read more on bread lines, in the previous issues of baking+biscuit international, 4 and 5.