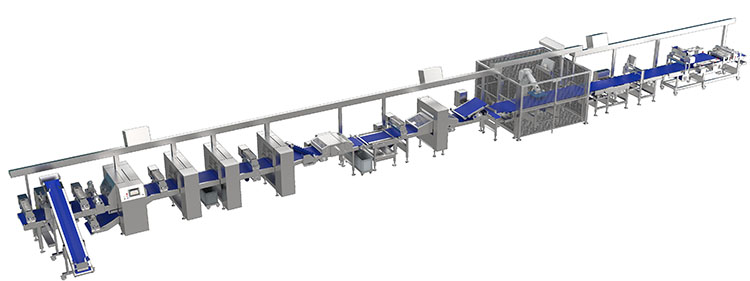

RONDO launched its most recent automated line for bread production, the Smart Bread Line, at iba 2023. It was designed to make more bread, faster, while reproducing artisan quality.

A market analysis dedicated to the world of bread allowed RONDO to identify a specific need in the small-medium industry segment for a flexible and modular line that would make different types of bread, an all-breads-in-one-machine concept. The experience of designing the ASTec industrial lines helped in designing the Smart Bread Line, RONDO explains: “In fact, we took advantage of our expertise to create a line capable of responding to semi-industrial needs while guaranteeing a final product with an artisanal look.”

With a modular configuration, the new bread line can process up to 1,000 kg of dough per hour for a wide range of breads. It is designed to improve ergonomics in production environments to increase efficiency and labor efforts. “The simplicity of use and ease of mobilization of the individual modules makes it a versatile and high-performance line,” its maker highlights. The modular design of the Smart Bread Line allows setups for the production of all bread categories, either cut, stamped, rounded, or molded. Niche and special requirement products such as gluten-free bread can also be made. “It is possible to create over 1,000 recipes,” RONDO adds.

The equipment changeovers are fast and easy to make, the specialist explains. Additional products can be added into production by replacing tools, such as the blades or molds. “The Smart Bread Line was created to have the product change as quickly as possible. Obviously, this depends on the workload, the number of families of bread products made, and the space the company has available in the production area, to name the main factors.” The line was created to meet the production capacity of 1,000 kg/h in a word schedule of two shifts per day.

The operator was also factored into the design of the line: programming, diagnostics, the speed of the conveyor belt and the thickness of the dough band are managed via HMI, for user-friendly operation.

Gentle dough processing was a priority; it is ensured from shaping the dough band through to placing the formed products in trays. This enables the Smart Bread Line to process all kinds of dough, especially difficult types such as highly hydrated and pre-fermented dough, with close control over its structure.

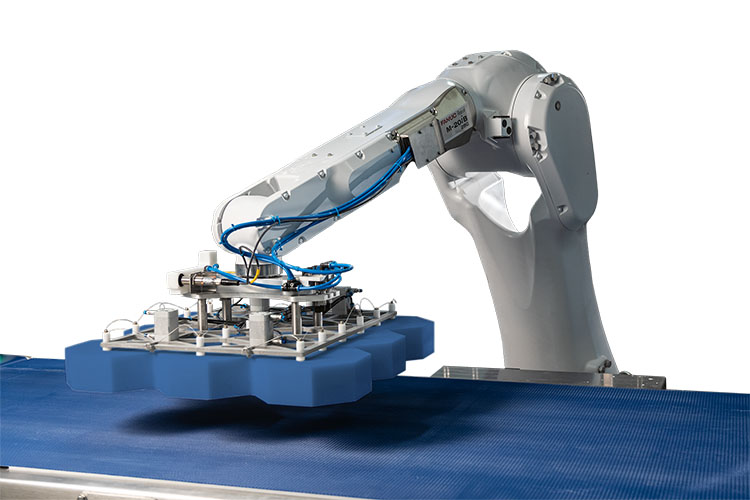

New automation features

Among the new technology developments that come with this bread line, the RONDObot is a notable feature. It is a round molding system that can process highly hydrated dough with long resting times. It is suitable for producing round rolls in various weights, shapes and sizes, contributing to the line’s flexibility. In addition, “RONDObot is an innovation in the oval molding process. The new cross-rolling movement of RONDObot permits the formation of oval shapes from small to big loaves,” says the specialist. The system can change between tools automatically, so that molders of different sizes can be used. Its rounding speed, number of rotations and width are all managed by its built-in software, with no mechanical intervention required. Several working cycles are available:

+ Standard rounding movement (round shaping)

+ Cross-rolling movement (oval shaping)

+ A combination of the two movements

More features

There are various additional features to choose from, to customize the Smart Bread Line to specific needs, such as different automatic feeding systems, different automatic seeding units and different automatic panning units.

Options for feeding systems include stocking hoppers with a feeding belt, floor-level stocking hoppers with a feeding belt, or just a feeding belt. For product differentiations, automatic seeding units are available, either top seeding units, or seeders for the top and the bottom of the product. For panning automation, one option is a unit with one or two trays, or a panning unit with an automated tray circuit. “The different options are available to meet the customer’s production requirements. The objective remains to simplify work and reduce employee workloads,” RONDO explains.

Safety and hygiene were also integrated into the design of the Smart Bread Line. In order to guarantee the integrity and safety of the final product, RONDO applied the same production methods when building the Smart Bread Line as those used to make industrial ASTec lines: “We apply the MOCA regulation, which serves to certify compliance with hygiene standards and to regulate the food contact of materials, such as steel, in our case.”

For best results

When baking fresh products, RONDO recommends changing the tools in line with the programming, respecting the logic per product family, to optimize production effiency: “We therefore want to avoid changing molds or blades in an unorganized and confusing way. This will save you time and money.”

Balancing product diversity and the optimum process efficiency requires a flexible technology solution, which takes all production steps of an array of products into consideration. It is also a matter of correctly planning the production using the line, throughout the day, the week and all year round.